Multifunctional bioceramic orbital implant as well as preparation technology and application thereof

A technology of bioceramics and preparation process, which is applied in the medical field and can solve problems such as orbital bone wear and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

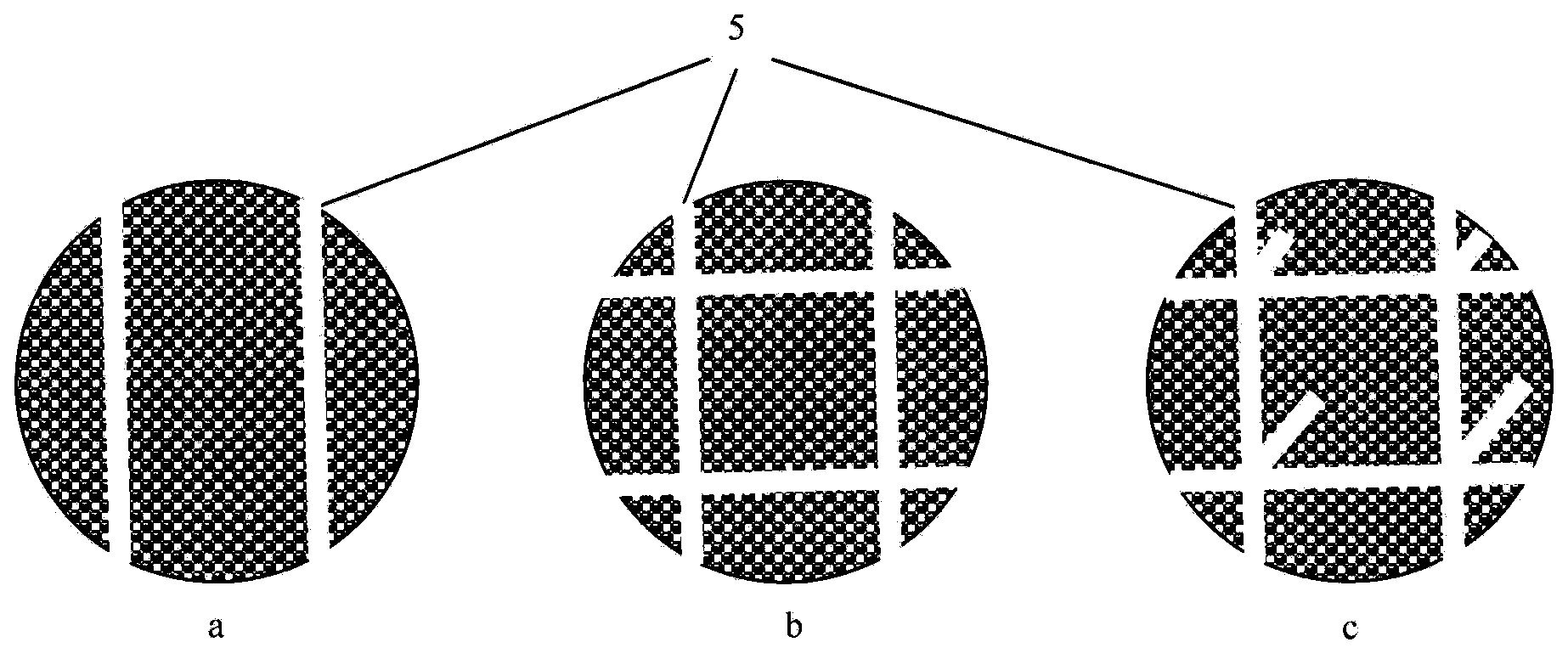

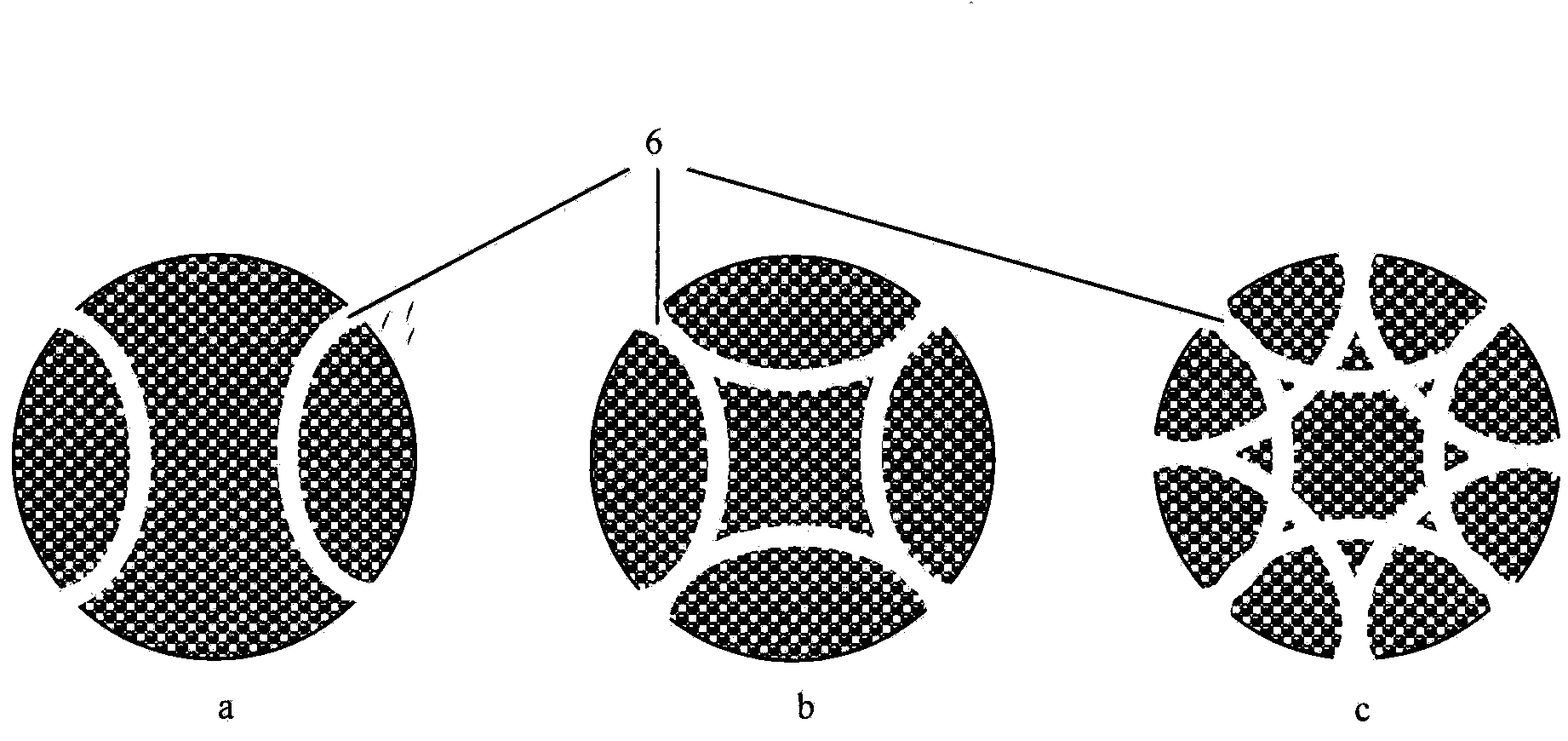

[0028] Embodiment 1: Set the final product as The hydroxyapatite (powder shrinkage rate 10%) bioceramic prosthetic eye platform. Select stainless steel to prepare the metal positive die mold, the required metal ball diameter=20*(1+0.10)=22mm, and the height of the ball holder, the inner diameter and the outer diameter are respectively 11, 22 and 66mm for processing ( Figure 4 ). Put the metal ball into the ball holder on the glass, the outer diameter of the jacket matches the ball holder and the plastic casing with a height of 10cm, pour 200ml of slurry containing 60% gypsum powder and 40% water, and solidify and demould to form a gypsum female mold . The female molds are paired and fixed in pairs to form a spherical cavity ( ), one of the female molds rotates at the lowest part of the concave The through hole is used to load the pore forming agent ( Figure 5 ).

Embodiment 2

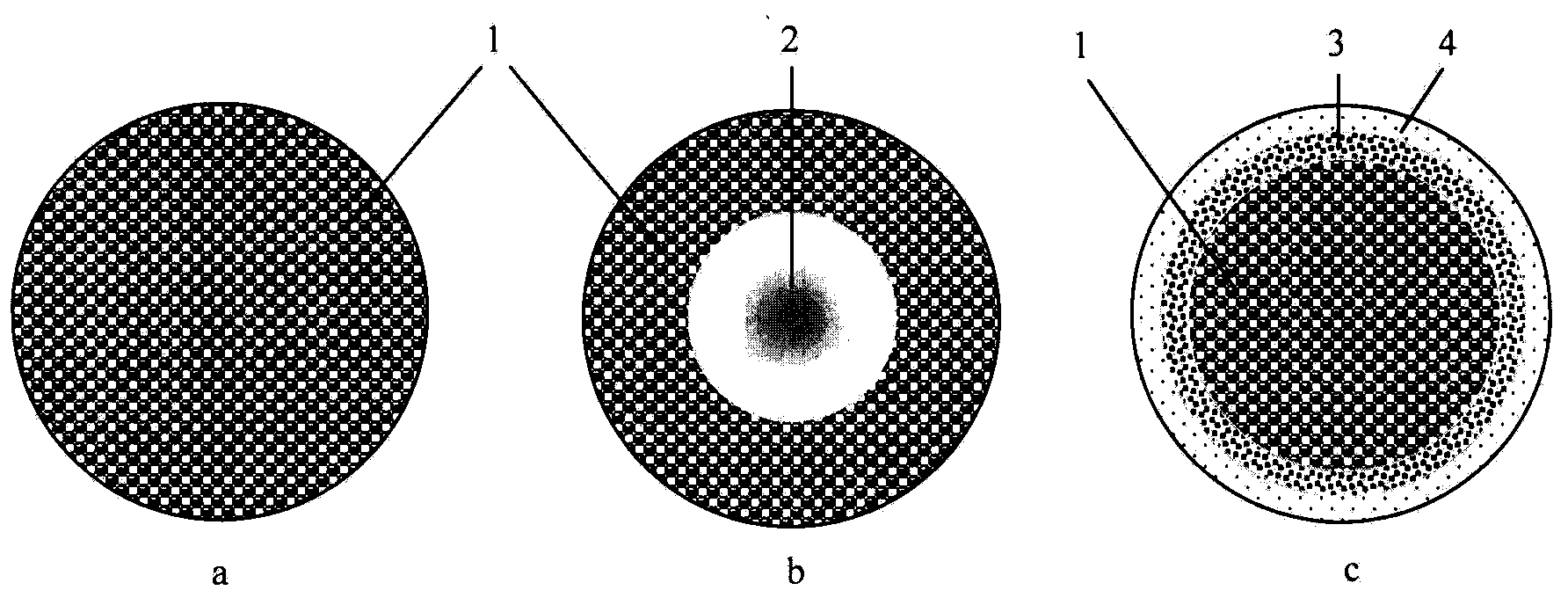

[0029] Example 2: Will Pour the PMMA pearl particles of μm into the composite female mold cavity of Example 1, add 8ml of acetone after checking the filling, add 20ml of pure water after 2 minutes, rinse and fix it into a spherical pore-forming scaffold, and dry it at 70°C for 48 hours. The hydroxyphosphate slurry was injected into a plaster mold loaded with a dry pore-forming bracket, and dried at 50°C for 48 hours to demould into a ceramic body. The ceramic body is baked at 300°C for 12 hours in a debinding furnace to remove organic matter, and sintered at 1200°C for 4 hours in a sintering furnace Hydroxyapatite homogeneous porous bioceramic prosthetic eye platform ( figure 1 Middle a).

Embodiment 3

[0030] Example 3: Prepare a spherical pore-forming stent according to the method in Example 2, and bake at 50°C for 12 hours to retain 20% of the water in the center of the sphere; then inject the tricalcium phosphate slurry into the plaster mold loaded with the pore-forming stent, Dry at 50°C for 48 hours to demould into a ceramic green body; the green body is baked at 300°C for 12 hours in a debinding furnace to remove organic matter, and sintered at 1100°C for 4 hours in a sintering furnace to form Tricalcium Phosphate Slurry Hollow Porous Bioceramic Prosthetic Eye Platform ( figure 1 Middle b).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com