Pure titanium powder forming method based on selected area laser melting technology

A technology of selective laser melting and forming method, applied in the direction of improving process efficiency, improving energy efficiency, etc., can solve the problems of difficult use environment of parts, low flexibility, affecting the life of parts, etc., to achieve good dynamic performance and high flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] This embodiment introduces the process of the present invention for preparing pure titanium porous structure parts.

[0075] The present invention adopts a 3D printing equipment model SLM-125HL produced by German SLM Solutions Gmbh, and the used supporting software is SLM AutoFab MCS1.1 or SLM AutoFab64 1.8 software that comes with the 3D printing equipment.

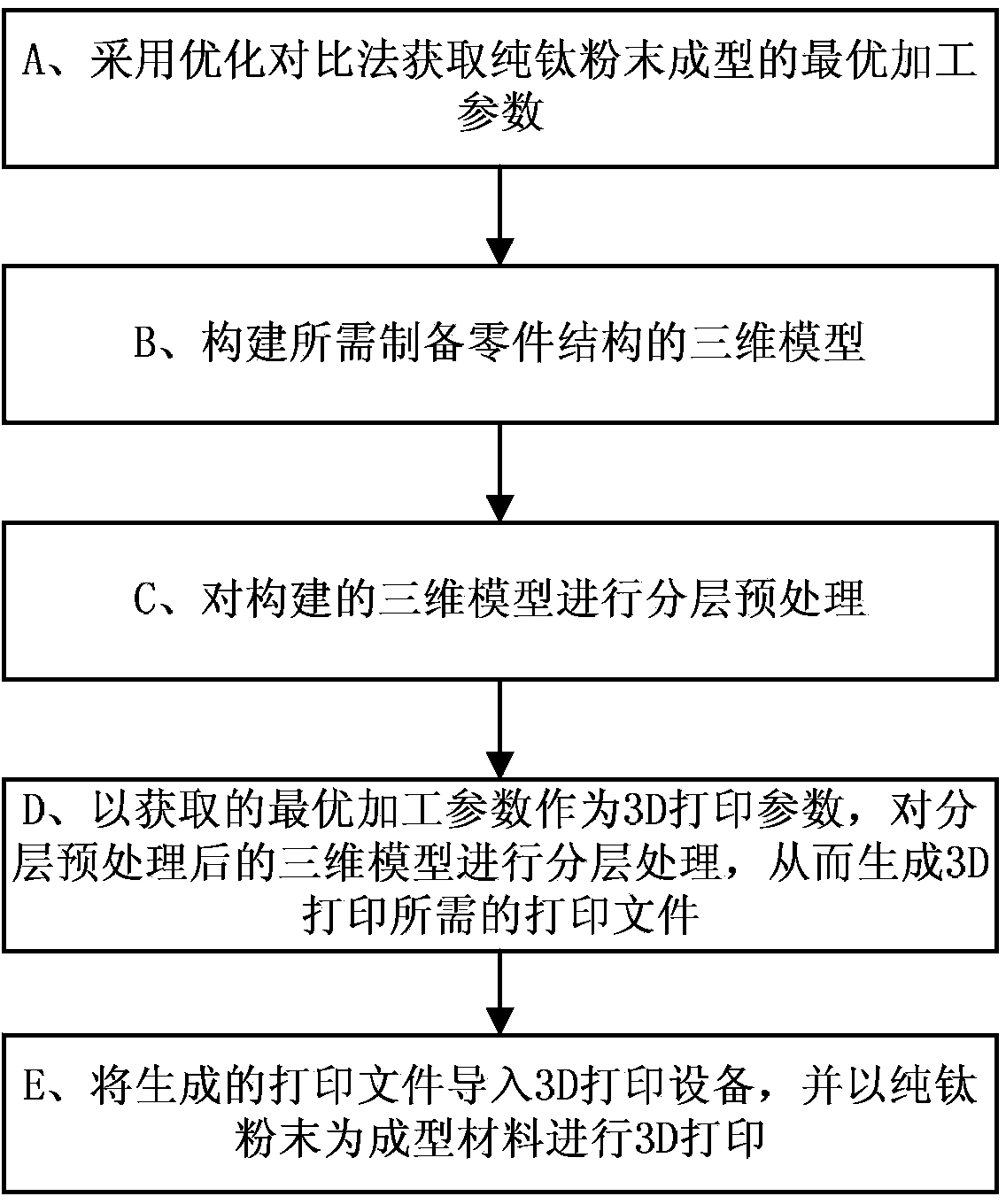

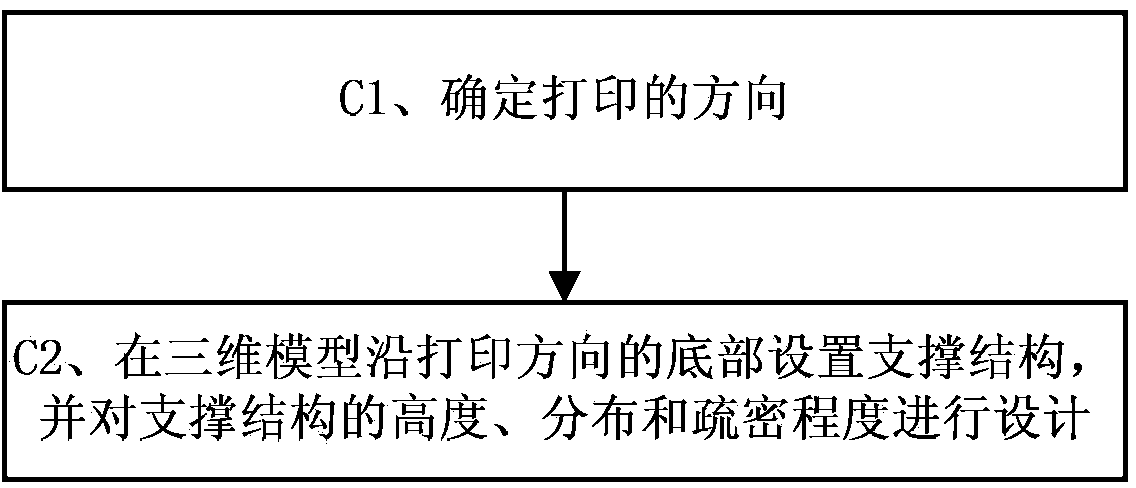

[0076] The process of the present invention for preparing pure titanium porous structure parts includes:

[0077] S1. Establish a three-dimensional model of the porous structure to be prepared in the computer.

[0078] According to the actual structure of the parts to be prepared, solidworks, UG, ProE and other engineering drawing software are used to design and build a three-dimensional model of the actual porous structure, and save it in STL format. Among them, the parameters of the three-dimensional model are based on the actual parameters of the porous structure, including the shape and size of the external whole, the...

Embodiment 2

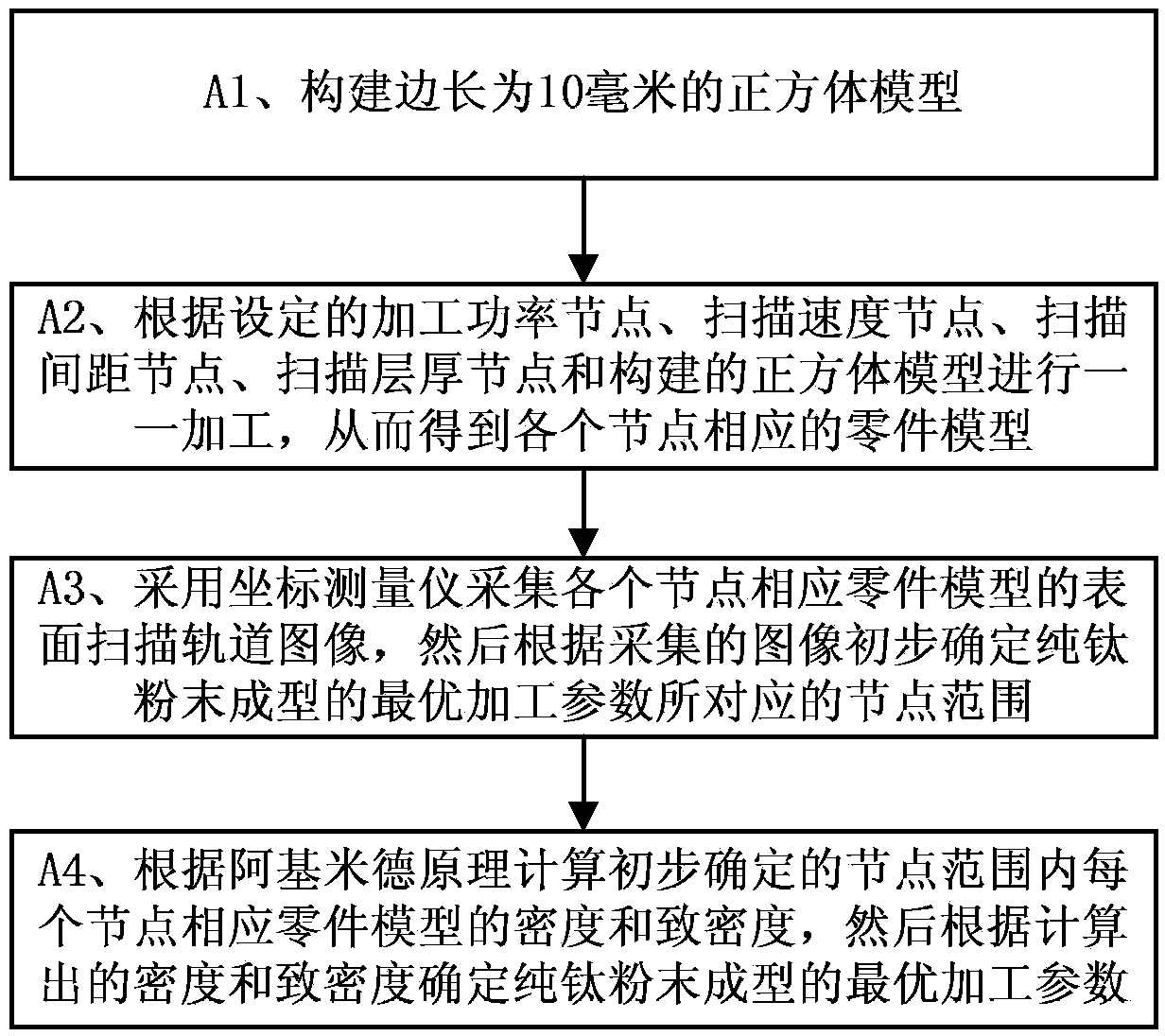

[0088] This embodiment introduces the specific process of obtaining the optimal processing parameters of pure titanium powder molding by using the optimization comparison method.

[0089] The invention first constructs a cube model structure with a unified structure, and then compares and calculates according to the significant technical effects produced by different changed processing parameters.

[0090] When performing comparative observation and calculation, the present invention uses the coordinate measuring instrument Quick View 200 to observe the surface scanning track of the model, and by processing the constructed cubic model, the parts after removing the support structure and smoothing the bottom surface are placed on the platform of the coordinate measuring instrument , And select the magnification 1.5 to 2 times to observe the surface melt channel state clearly and comprehensively.

[0091] The comparison of the significant technical effects produced by the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com