Argon arc welding back shielding gas device for vertical welding seam

A technology of argon arc welding and shielding gas, which is applied to devices, auxiliary devices, arc welding equipment, etc. for supplying/removing shielding gas. The effect of grinding and sealing welding process, improving welding efficiency, reducing labor intensity and engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

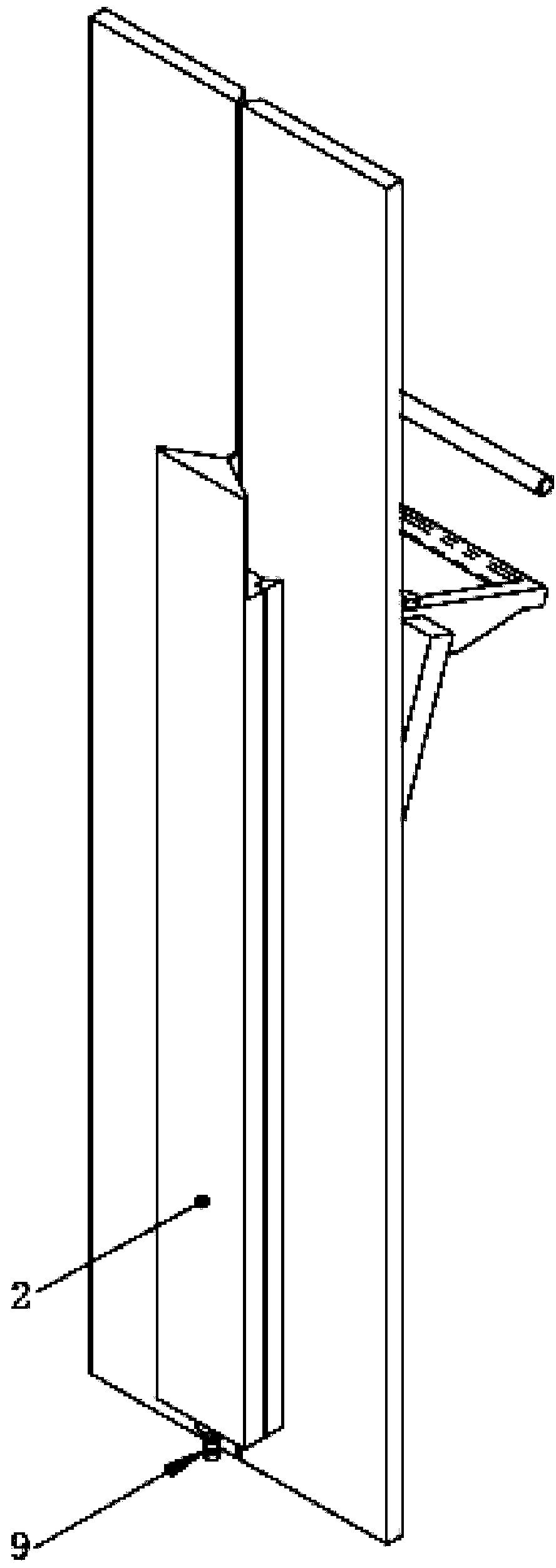

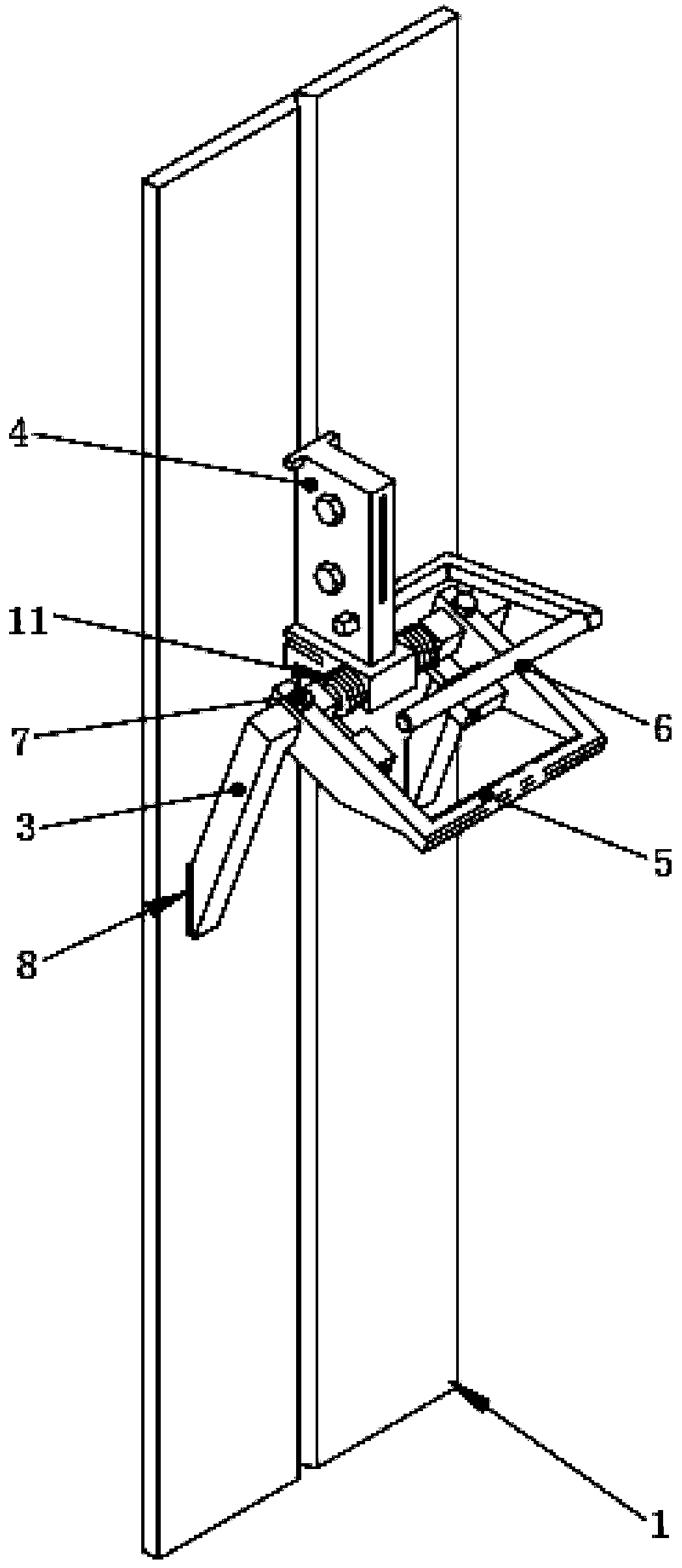

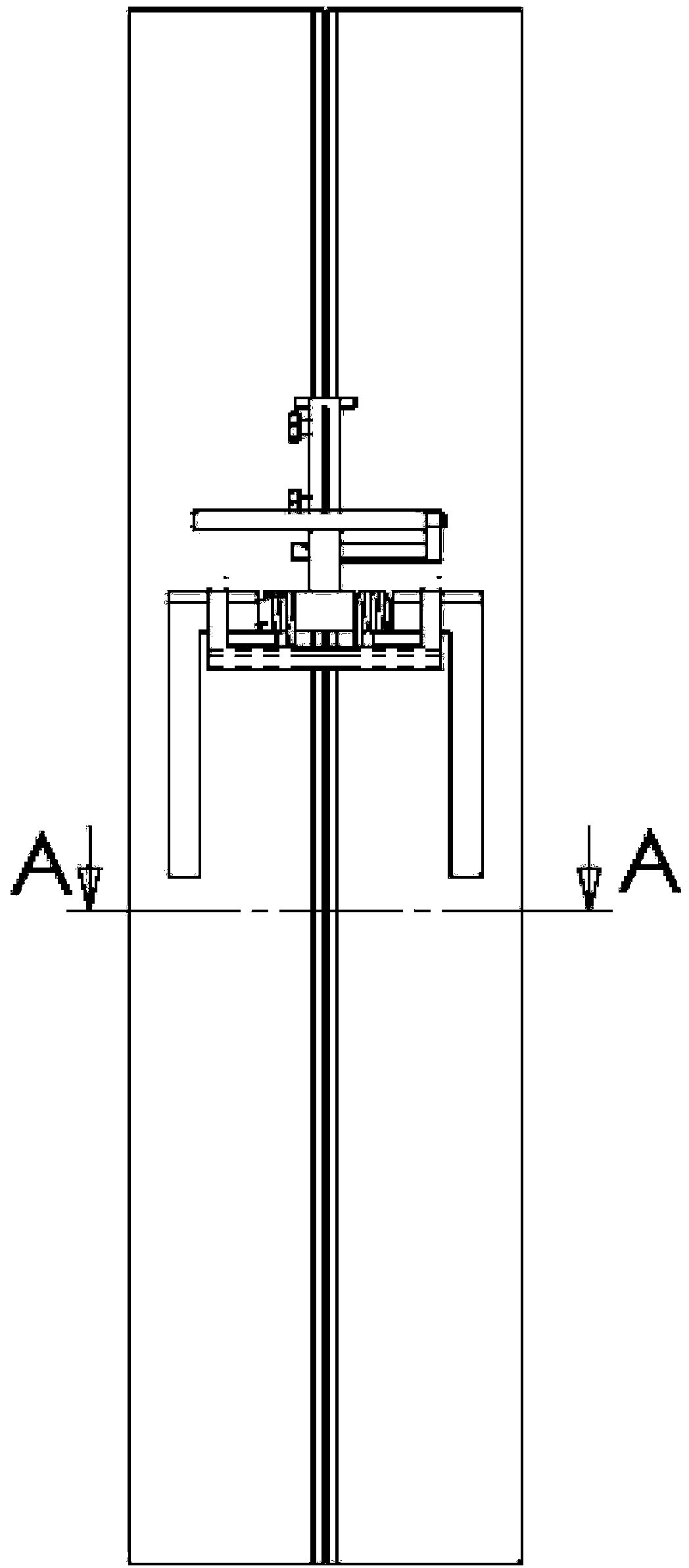

[0021] like Figure 1-6 As shown, the present invention includes: a guide rod 2, a clamping structure connected to the guide rod 2; wherein, the guide rod 2 is used as a protective gas delivery structure, and its shape is: a rectangular structure; the top of the guide rod 2 is a triangle, and the triangle A protruding insertion piece 21 is connected to the guide rod 2 by welding, and the insertion piece 21 is used to pass through the gap between the paired welds of the workpiece 1 to be welded; the guide rod 2 below the insertion piece 21 is fixed with a Flexible sealing strip 10, the flexible sealing strip 10 is a frame-shaped structure, and the section of the sealing strip 10 is "V" shaped, and the sharp corner end is in contact with the workpiece 1 to be welded, which can be better compatible with the uneven surface of the workpiece and achieve good seal. The sealing strip 10 is fixed at the peripheral position of the rectangular guide rod 2; a connector 9 is installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com