Production method and device capable of reducing polypropylene ash

A production method and polypropylene technology, applied in the field of polypropylene production, can solve the problems of difficult implementation and low usage of alkyl aluminum, and achieve the effects of low ash content, good effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

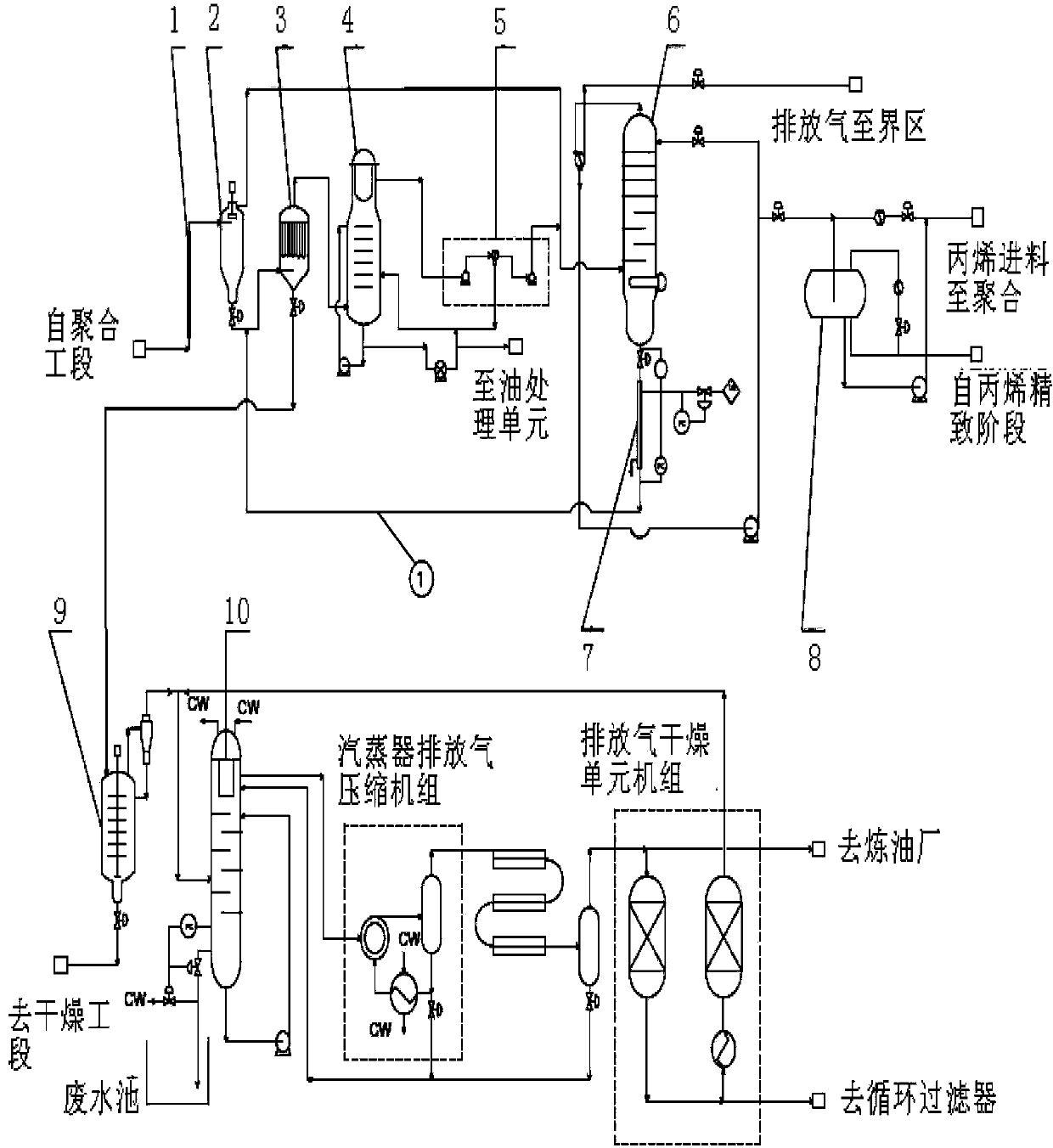

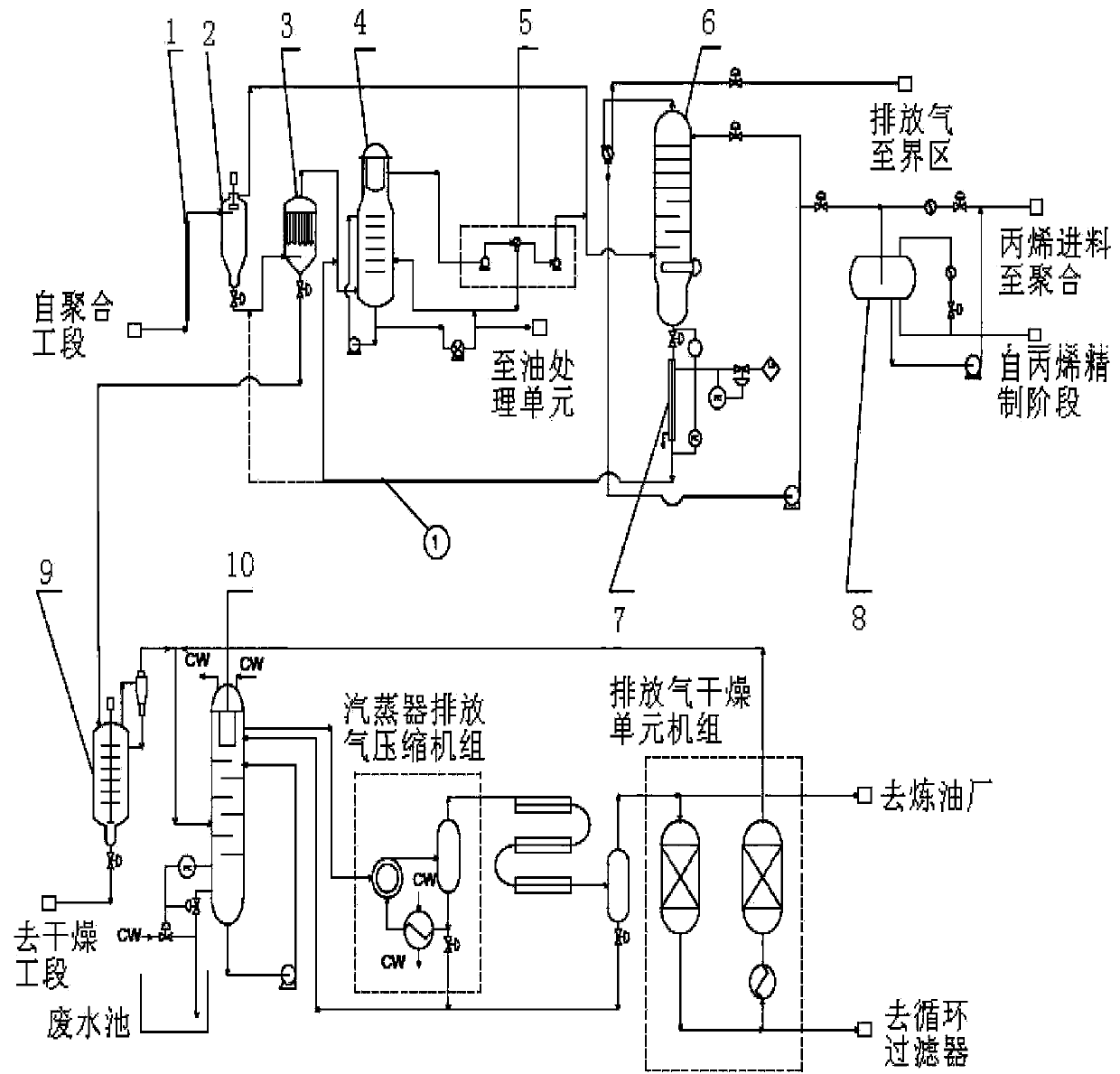

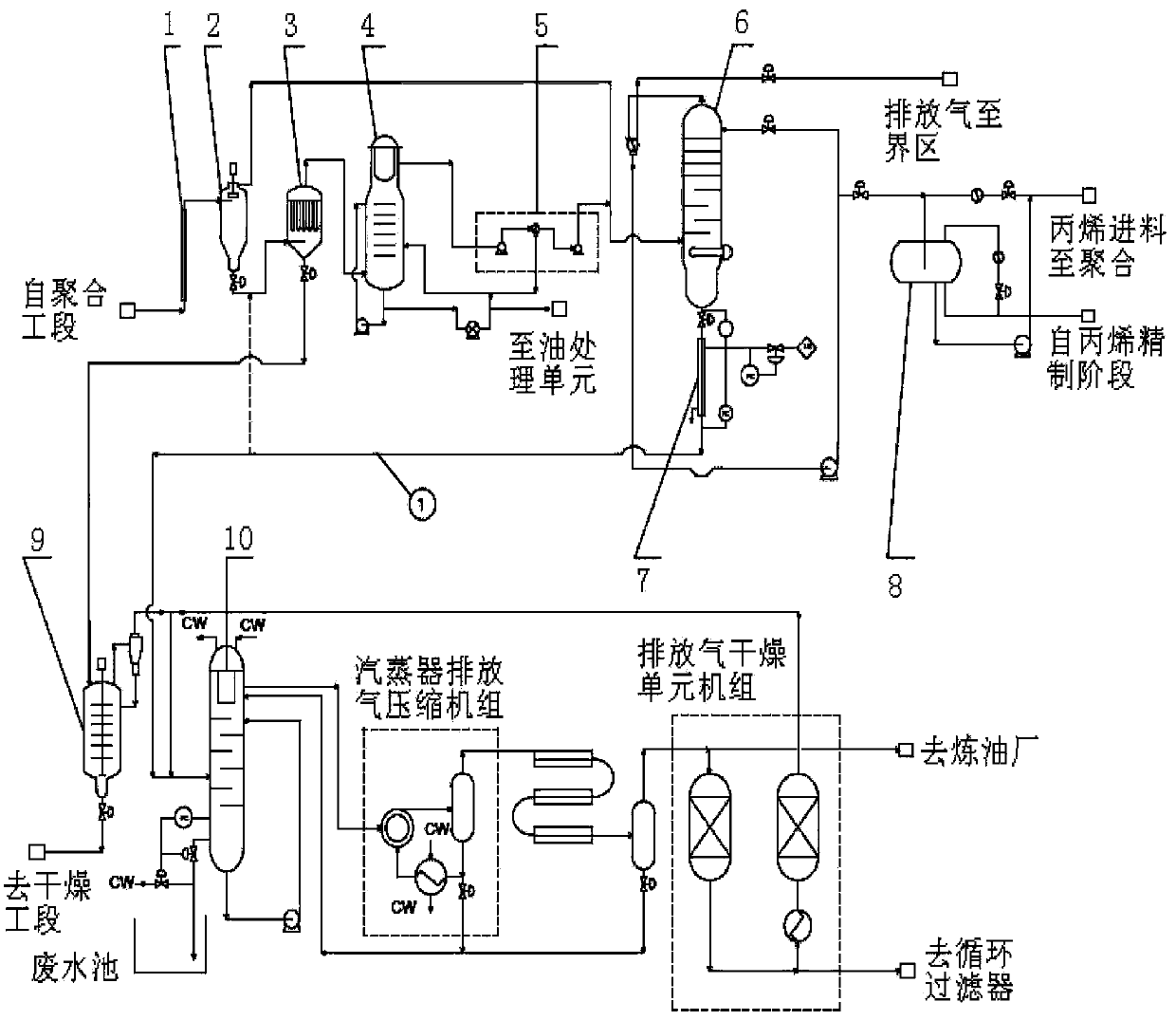

[0056] The concrete production technological process of present embodiment and the improvement to above-mentioned comparative example are as figure 2 shown. The reaction products of alkylaluminum and alkylaluminum with impurities are discharged from the loop reactor in the polymerization section along with a large amount of polypropylene and liquid propylene monomer and then enter the first flash line 1. After the liquid propylene monomer is flash vaporized, it is Gas-solid separation is carried out in tank 2. The reaction product containing polypropylene powder, gaseous propylene monomer, alkylaluminum and alkylaluminum and impurities separated from the flash tank 2 enters the high-pressure washing tower 6 for washing. The polypropylene separated from the flash tank 2 enters the bag filter 3 for low-pressure gas-solid separation (working pressure is 0.06Mpa), the solid phase flows into the downstream steaming and drying process, and the gaseous propylene monomer and system ...

Embodiment 2

[0059] The concrete production technological process of present embodiment and the improvement to above-mentioned comparative example are as figure 2 shown. The reaction products of alkylaluminum and alkylaluminum with impurities are discharged from the loop reactor in the polymerization section along with a large amount of polypropylene and liquid propylene monomer and then enter the first flash line 1. After the liquid propylene monomer is flash vaporized, it is Gas-solid separation is carried out in tank 2. The reaction product containing polypropylene powder, gaseous propylene monomer, alkylaluminum and alkylaluminum and impurities separated from the flash tank 2 enters the high-pressure washing tower 6 (working pressure is 1.8Mpa) for washing. The polypropylene separated from the flash tank 2 enters the bag filter 3 for low-pressure gas-solid separation (working pressure is 0.06Mpa), the solid phase flows into the downstream steaming and drying process, and the gaseous ...

Embodiment 3

[0062] The concrete production technological process of present embodiment and the improvement to above-mentioned comparative example are as figure 2shown. The reaction products of alkylaluminum and alkylaluminum with impurities are discharged from the loop reactor in the polymerization section along with a large amount of polypropylene and liquid propylene monomer and then enter the first flash line 1. After the liquid propylene monomer is flash vaporized, it is Gas-solid separation is carried out in tank 2. The reaction product containing polypropylene powder, gaseous propylene monomer, alkylaluminum and alkylaluminum and impurities separated from the flash tank 2 enters the high-pressure washing tower 6 (working pressure is 1.8Mpa) for washing. The polypropylene separated from the flash tank 2 enters the bag filter 3 for low-pressure gas-solid separation (working pressure is 0.06Mpa), the solid phase flows into the downstream steaming and drying process, and the gaseous p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com