Method for treating waste electrolyte generated in production of electrolytic aluminium

A waste electrolyte and electrolytic aluminum technology, which is applied in the field of waste electrolyte in the production of electrolytic aluminum, can solve the problems of extra consumption of carbon anodes, large consumption, and accumulation of waste cryolite that cannot be processed, so as to reduce additional consumption, prolong service life, The effect of reducing exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0017] Example 1 Application of water-based coating

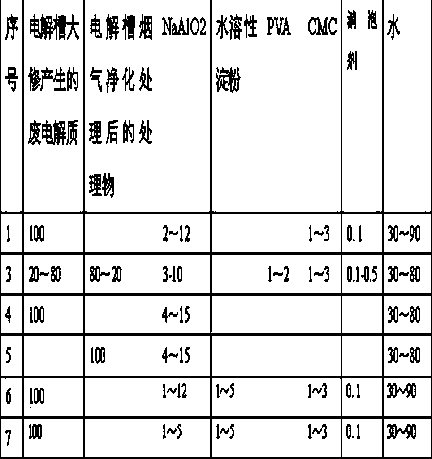

[0018] The formulation of the coating is shown in Table 1

[0019] Table 1 Formulation of water-based coating

[0020]

[0021] The waste electrolyte produced by the overhaul of the electrolyzer and the treated product after the flue gas purification treatment of the electrolyzer

[0022] Note: The aggregate of the paint is 100%, and the other contents are the percentage of the aggregate

[0023] Prepare the coating according to the formula in Table 1, apply (or spray) the coating evenly on the upper surface and side upper surface of the carbon anode during the cooling stage of prebaked anode preparation, apply (or spray) 1 to 5 times, and the coating thickness 0.2 ~ 8mm, the coating can be composed of a single coating or a composite coating, and then dry the coating for industrial electrolytic aluminum production.

[0024] The results of the electrolytic cell test show that the electrolysis process is stable, the par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com