Wheeled loader

A wheel loader and tire technology, applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, climate change adaptation, etc. and other problems, to achieve the effect of good floating performance, good performance and small wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

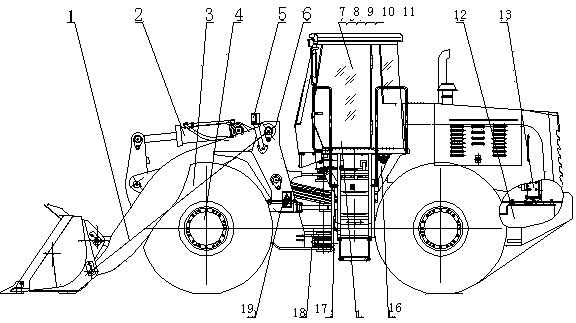

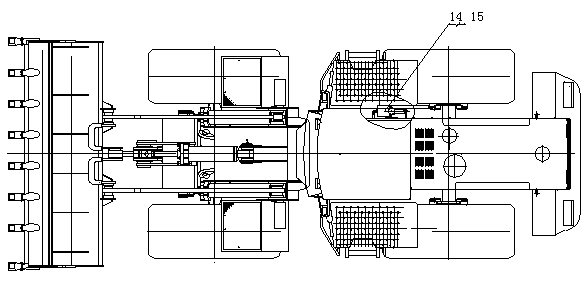

[0021] Below in conjunction with accompanying drawing, the present invention will be further described: a kind of wheel loader, comprises a. tire, and tread pattern adopts desert to use E-7 pattern tubeless tubeless tire;

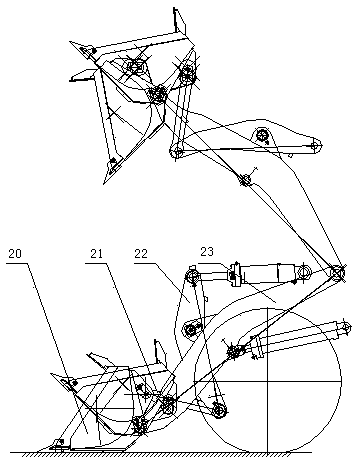

[0022] b. Working device. The working device is matched with the tires. It mainly consists of boom assembly, rocker arm assembly, bucket assembly, and tie rod assembly. The components are connected by pin shafts, and each pin shaft is designed with lubrication. Oil passage, oil seals are installed at both ends of the hinge;

[0023] c. Walking platform assembly, the said walking platform assembly complies with ergonomics, and mainly consists of walking platform, handrails, ladders and brackets; handrails, ladders, brackets and walking platform are connected by bolts, and then rigidly connected as a whole to the on the frame;

[0024] d. Engine, the engine described is a desert-type air filter;

[0025] e. Radiator assembly, said radiator assembly is a des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com