Steel tube bundle combined structure consisting of steel plates and L-shaped steel

A combined structure and steel pipe bundle technology, which is applied in the direction of building components, building structures, building materials, etc., can solve the problems of complex component production, a large amount of labor, and difficult construction, and achieve reliable product quality, fast production speed, and flexible division. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

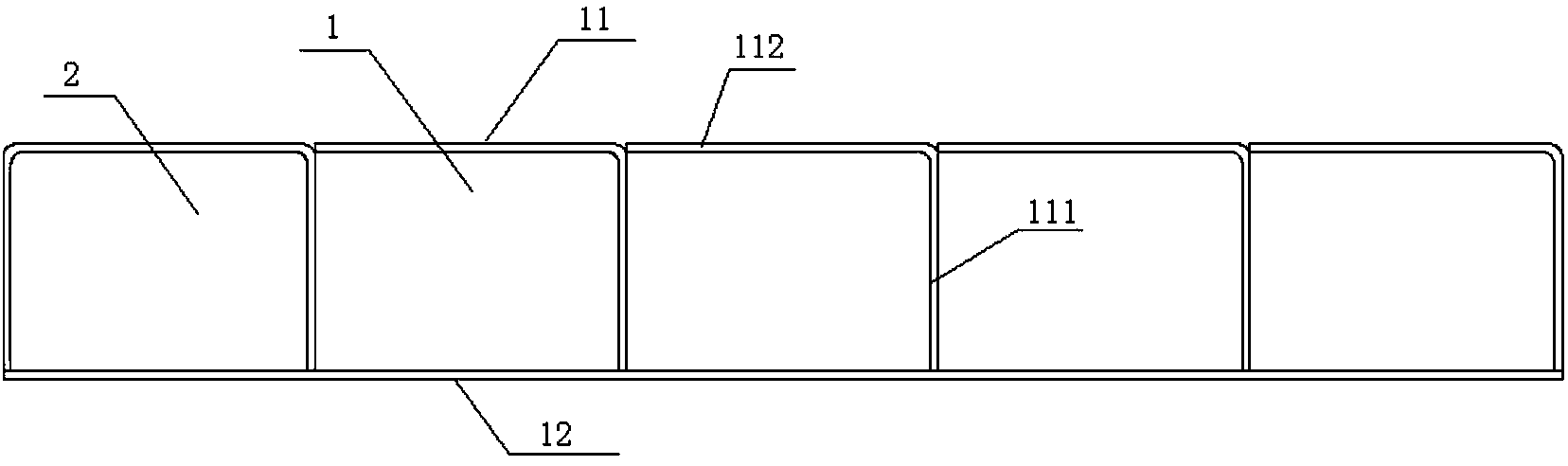

[0021] refer to figure 1 , a steel pipe bundle composite structure composed of steel plates and L-shaped steel, which is composed of a steel pipe bundle assembly, the steel pipe bundle assembly is composed of a plurality of steel pipe units 1 connected in sequence, and the steel pipe units 1 have cavities, so Pouring concrete in the cavity mentioned above;

[0022] The steel pipe unit 1 is composed of a plurality of L-shaped profiles 11 spliced in the same direction on the continuous flange 12, and each L-shaped profile 11 is formed by connecting a web 111 and a flange plate 112 perpendicular to each other. The plate 111 is vertically welded on the continuous flange 12, and the free end of the flange plate 112 is connected to the bend of the previous L-shaped profile; the flange plate 112 of the L-shaped profile is spliced to form a joint with the continuous flange 12 opposing flanges;

[0023] The L-shaped section and the web and continuous flange of the adjacent L-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com