Steel tube bundle combined structure provided with arc type wavy web

A combined structure and steel pipe bundle technology, which is applied to building components, building structures, building materials, etc., can solve the problems of difficult construction, complicated component production, and a large amount of labor, so as to achieve reliable product quality, labor saving, and fast production speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

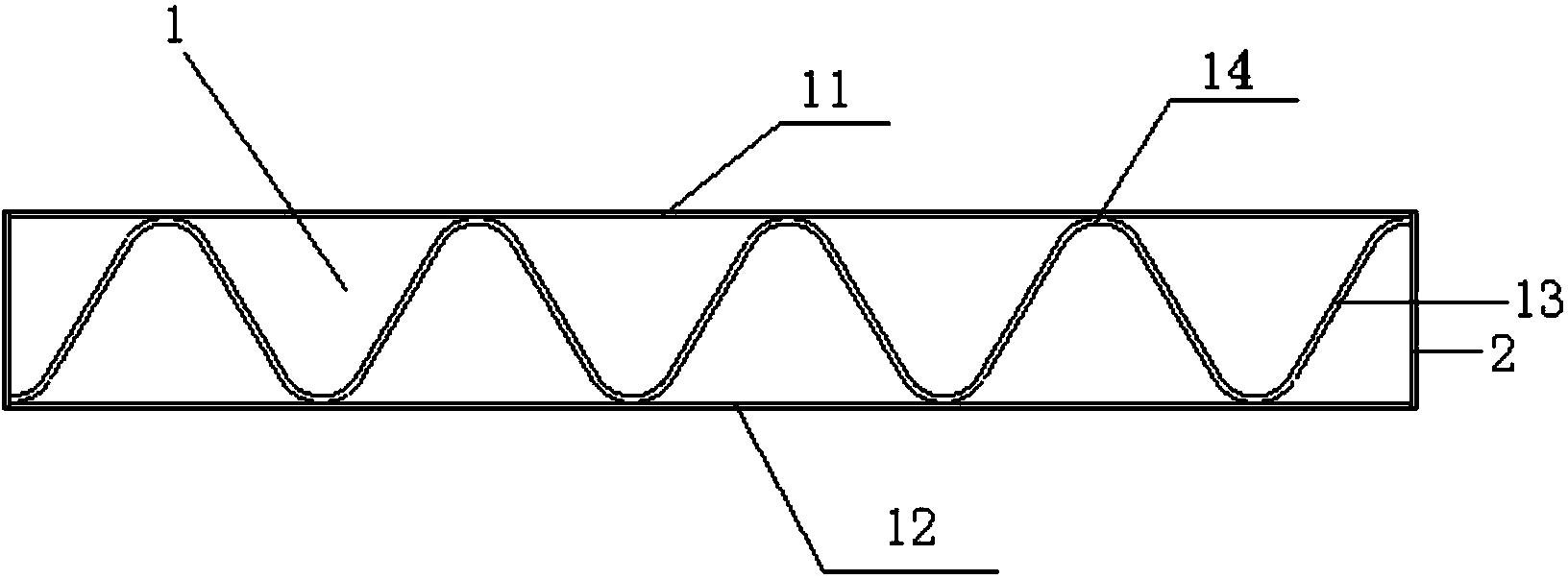

[0023] refer to figure 1 , an arc-shaped corrugated web steel pipe bundle composite structure, which is composed of a steel pipe bundle assembly, the steel pipe bundle assembly is composed of a plurality of steel pipe units 1 sequentially connected, the steel pipe units have cavities, and the Pouring concrete in the cavity;

[0024] The steel pipe unit 1 includes an upper flange 11 and a lower flange 12, and the upper flange 11 and the lower flange 12 are continuous steel plates;

[0025] The wavy continuous web 13 is arranged between the upper flange 11 and the lower flange 12, the continuous web 13 is composed of arc segments, the size and shape of adjacent arc segments are the same, and the opening faces On the contrary, the arc top 14 of the arc segment is arranged on the upper flange 11 or the lower flange 12;

[0026] The arc segment and the upper flange 11 or the lower flange 12 jointly enclose a steel pipe unit;

[0027] The arc segment constitutes a partition betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com