A reciprocating dynamic seal

A technology of dynamic seals and seals, applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problems of seal failure, excessive wear, large friction, etc., to improve sealing performance, prolong service life, and produce low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Describe the present invention below in conjunction with specific embodiment:

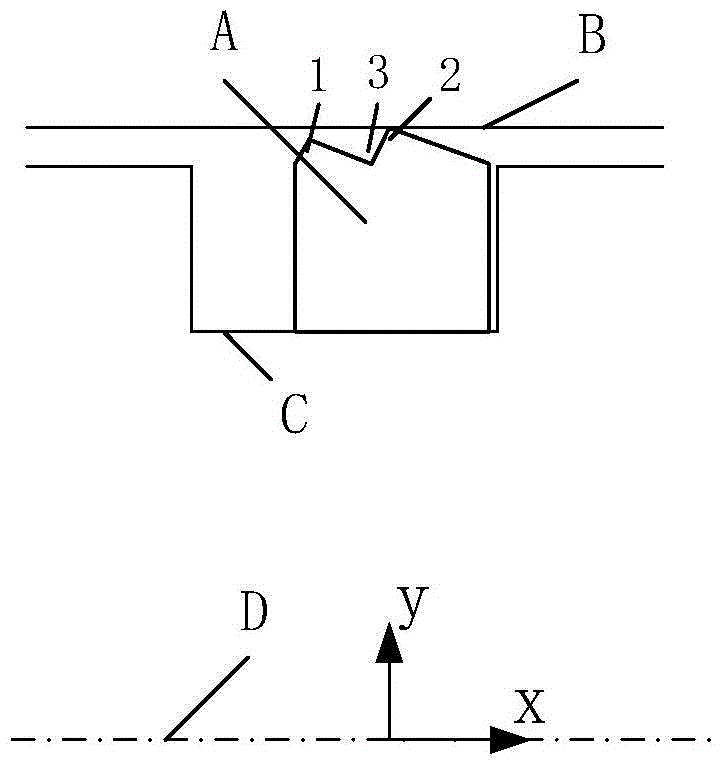

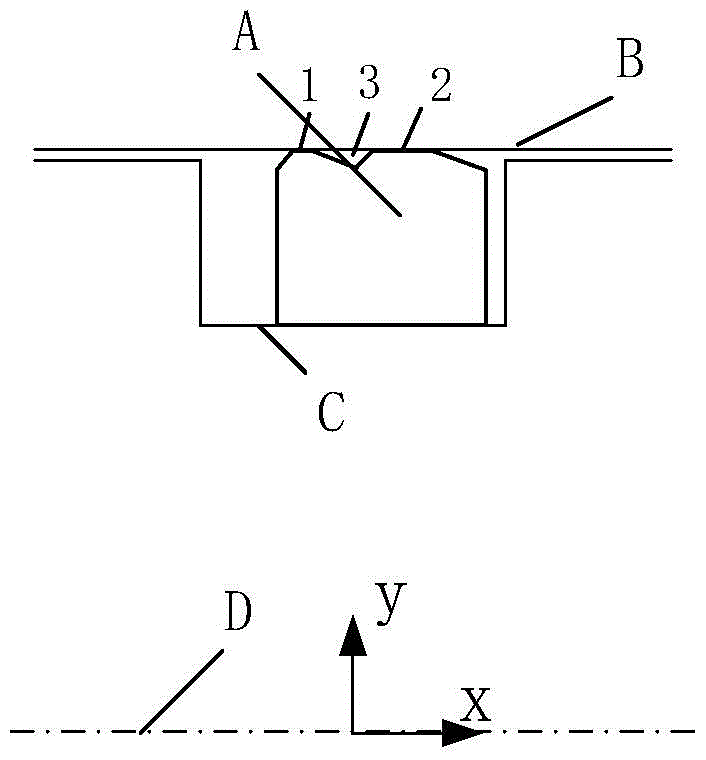

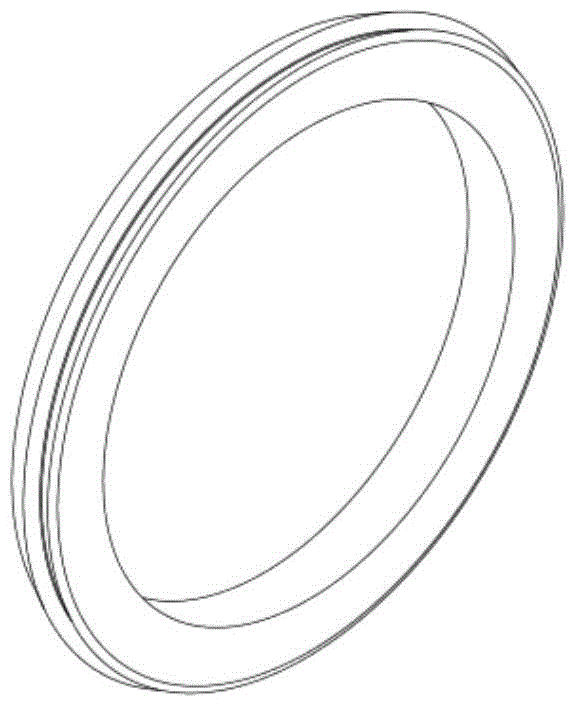

[0017] Refer to attached figure 1 , the seal in this embodiment is used for the sealing fit of the flange connection. Such as figure 1 As shown, the seal is a ring-shaped structure, the direction of the axis of symmetry is defined as the x direction, and the direction of the axis of symmetry perpendicular to the sealing ring is defined as the y direction.

[0018] The seal in this embodiment is made of rubber material, and its cross-sectional shape is as follows: figure 1 . The positive direction of the y-axis of the seal, that is, there are two rings of serrated teeth on the outer ring surface of the seal, which are used to produce two sealing contact surfaces, namely the front sealing surface and the rear sealing surface. After the seal is installed, it is close to the sealed medium. The sealing surface is the front sealing surface, and the corresponding circle of saw-shaped teeth is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com