Boiler drum water level control method based on fuzzy neural network PID (Proportion Integration Differentiation) control

A fuzzy neural network and boiler drum technology, which is applied in the fields of industrial automation control and process industry, can solve the difficulty of coordinated debugging of fuzzy neural network PID control strategy and control system, affect the application effect of boiler drum water level control, and update the control strategy online. The efficiency is difficult to grasp and other problems, so as to improve the communication efficiency, improve the adaptive ability, and improve the real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

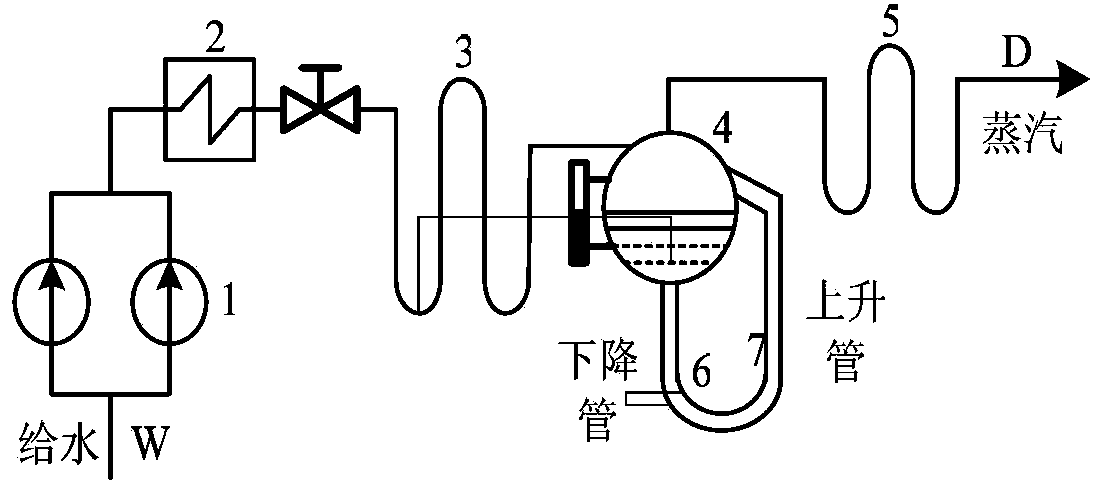

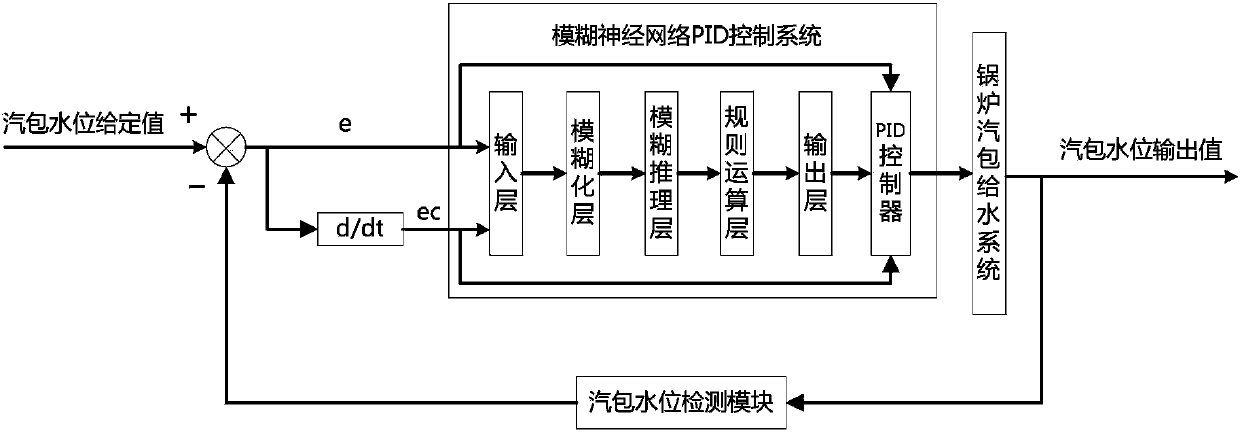

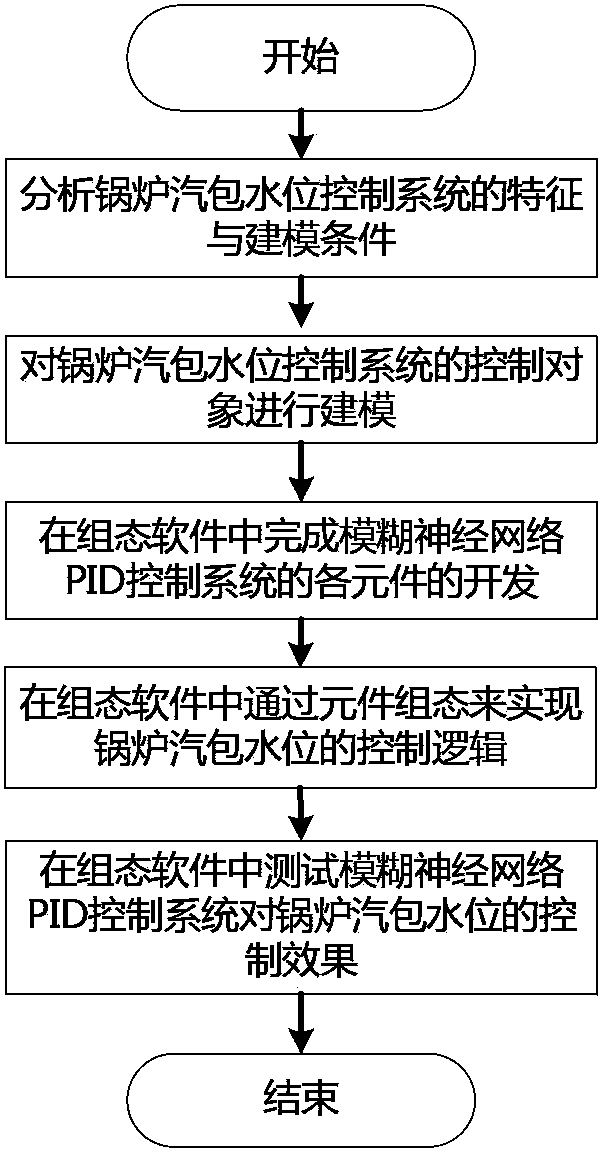

[0017] see figure 2 with image 3 Shown, the present invention is a kind of method based on the boiler drum water level control of fuzzy neural network PID control, the boiler drum water level control system involved in the method (such as figure 2 shown) is composed of a fuzzy neural network PID control system and a boiler drum water supply system; the method includes the following steps:

[0018] Step 1. Analyze the characteristics and modeling conditions of the boiler drum water level control system; specifically: Step 10. Obtain the control object of the boiler drum water level control system and the influencing factors of the control object. The control object is the steam drum, and the control object The influencing factors include changes in water supply, combustion, steam load and steam pressure;

[0019] Step 20, obtain the dynamic characteristics of the steam drum water level control, the dynamic characteristics include: when the feedwater flow of the boiler drum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com