Quantitative determination method for cross section porosity of loose mineral

A technique for quantitative determination and porosity, applied in the direction of measuring devices, permeability/surface area analysis, suspension and porous material analysis, etc., to achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

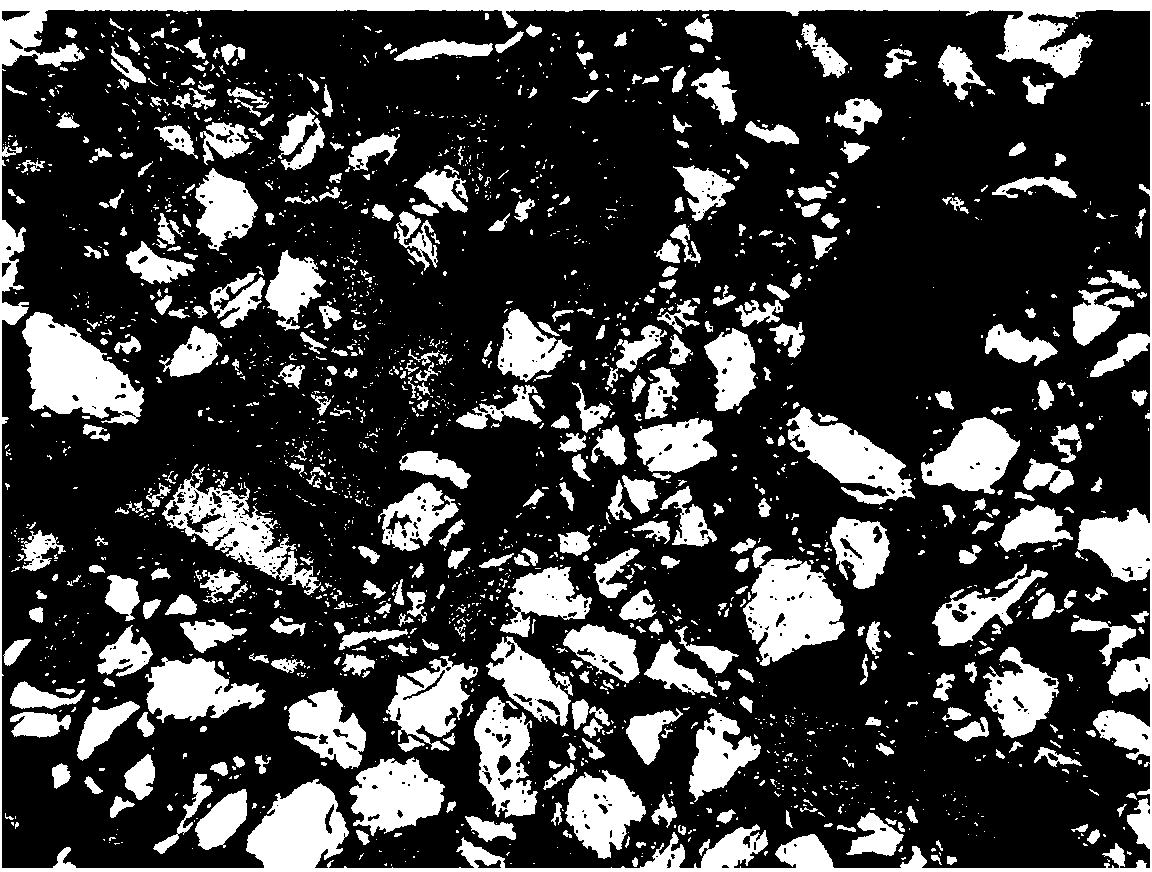

Image

Examples

Embodiment Construction

[0017] Hereinafter, an exemplary embodiment of the method for quantitatively determining the cross-sectional porosity of a loose mineral according to the present invention will be specifically described.

[0018] According to an exemplary embodiment of the present invention, the quantitative determination method of the cross-sectional porosity of loose minerals mainly includes the steps of sample preparation-image acquisition-porosity measurement-drawing the cross-sectional porosity change curve, etc. The determination method of the present invention is applicable to Sintered ore, molten slag and other loose minerals, but the present invention is not limited thereto.

[0019] Each step of the present invention will be described in detail below.

[0020] Step a:

[0021] Epoxy resin is used to vacuum-mount representative loose minerals to obtain mosaic samples, cut the mosaic samples and expose the cross-section of loose minerals, and use the cross-section as the observation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com