Cleaning control method of particulate matters on probes of probe card

A control method and particle technology, which is applied to the components of electrical measuring instruments, measuring devices, instruments, etc., can solve the problems that affect the accuracy of contact resistance detection, test PAD and metal wire short circuit, and device burnout, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

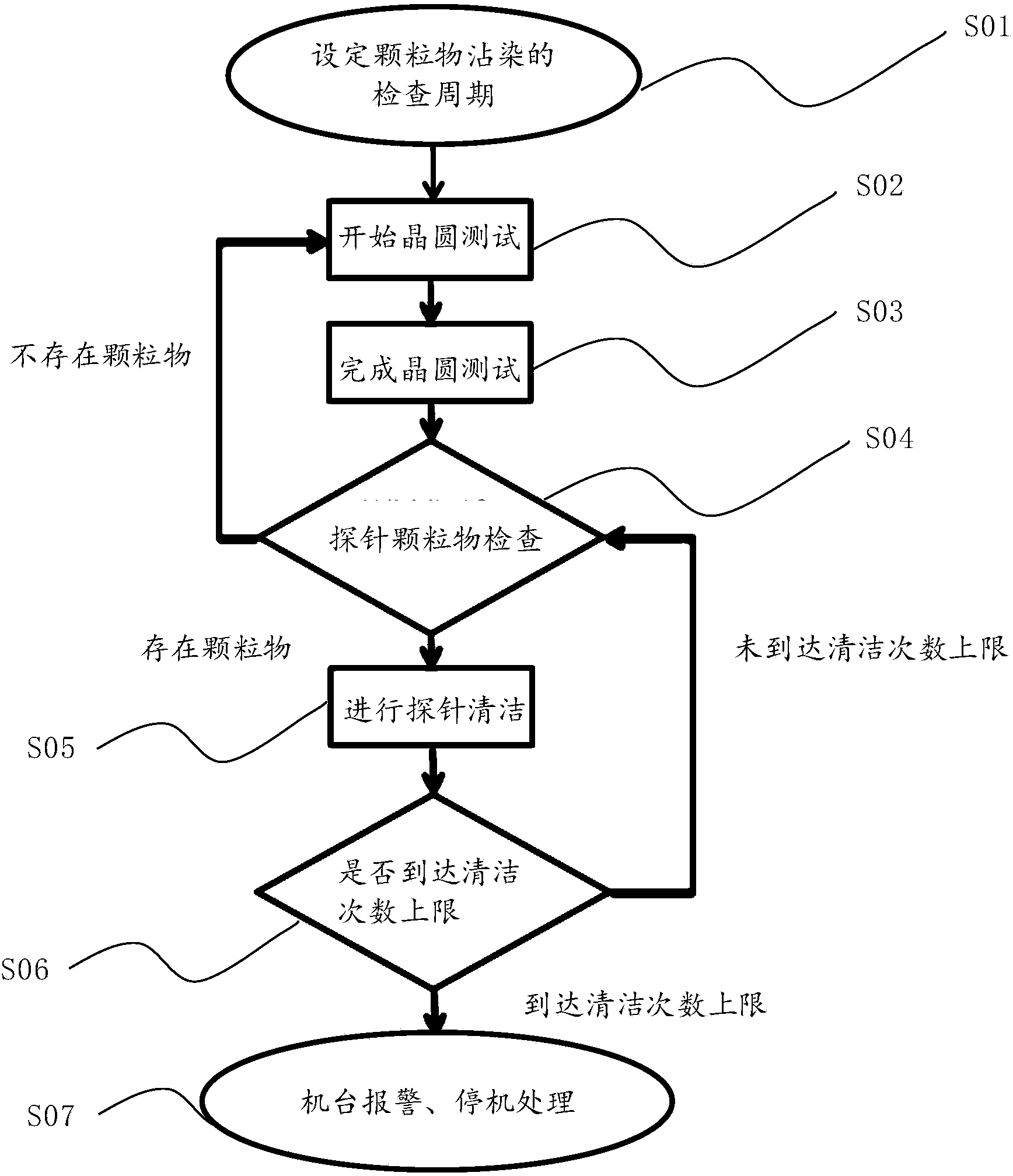

[0030] In this example, please refer to figure 1 , figure 1 It is a control flow chart of a particle cleaning control method of a probe card probe of the present invention. As shown in the figure, the particle cleaning control method of the probe card probe of the present invention is implemented through the following steps:

[0031] Step S01: Set the inspection cycle for particle contamination. The inspection cycle of the particle contamination of the probe is set in the probe card machine, and the inspection cycle is set to perform the inspection of the particulate contamination of the probe after the electrical test of each wafer is completed.

[0032] Step S02: Start wafer test. According to the inspection cycle, the electrical test of each wafer is started.

[0033] Step S03: complete the wafer test. Complete the electrical test on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com