Communication cable

A communication cable and cable core technology, applied in communication cables, insulated cables, cables, etc., can solve the problem that the cable sheath material cannot meet the harsh working environment, and achieve excellent oil resistance, strong heat insulation performance, and good insulation and shielding effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

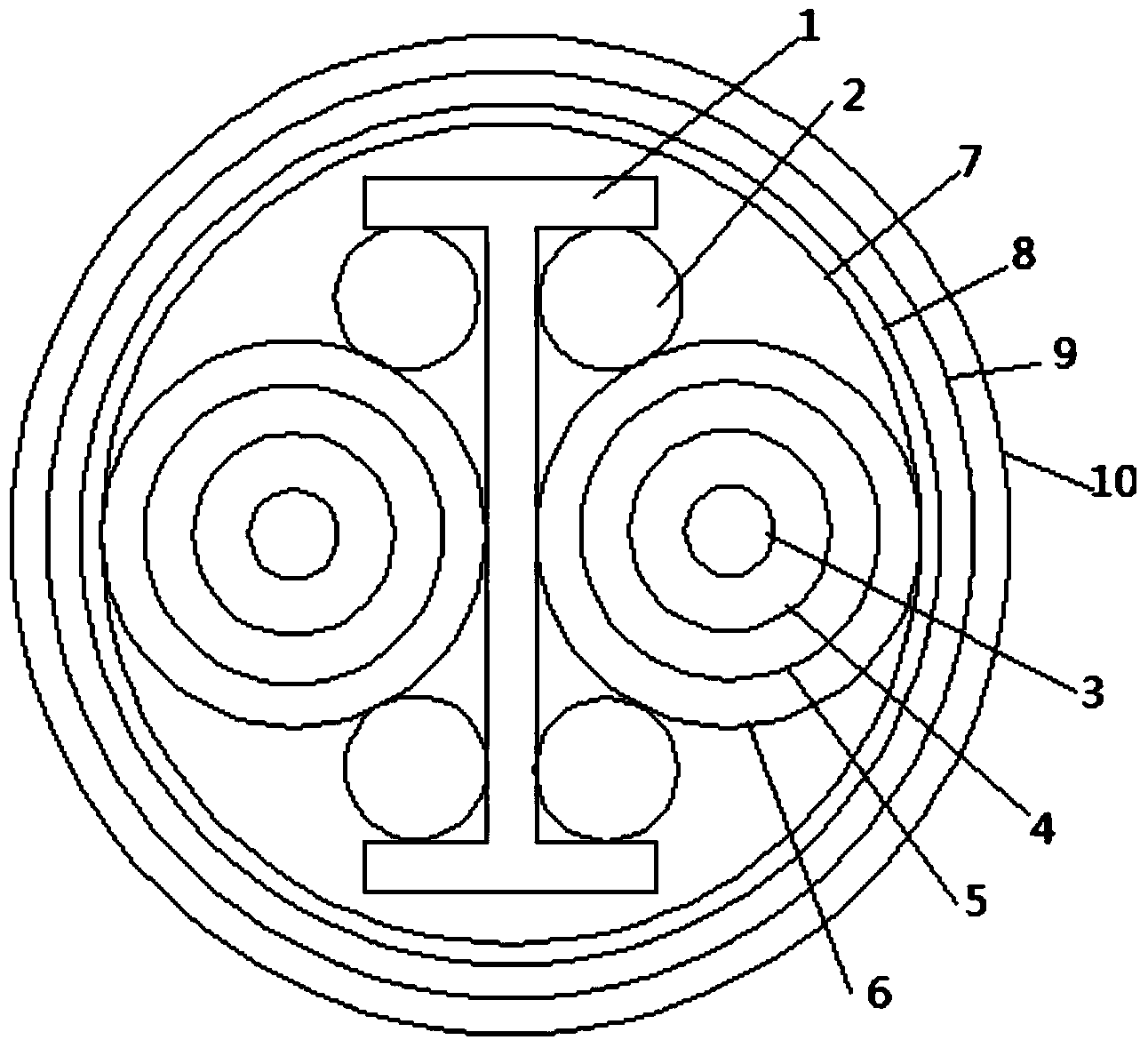

[0011] Such as figure 1 As shown, a communication cable includes a cable core, and the cable core includes an I-shaped rubber skeleton 1, and wire cores are respectively placed on the left and right sides of the I-shaped rubber skeleton 1, and each wire core is connected to the Elastic rods 2 are respectively arranged between the front and rear ends of the I-shaped rubber skeleton 1, and the wire core includes a conductor 3, and the outside of the conductor 3 is covered with a polyperfluoroethylene insulating layer 4, tin-plated Steel wire braided shielding layer 5 and inner sheath 6 are coated with glass wool rope winding layer 7 , aluminum-plastic composite film shielding layer 8 , heat insulation layer 9 and outer sheath 10 on the outside of the cable core in sequence.

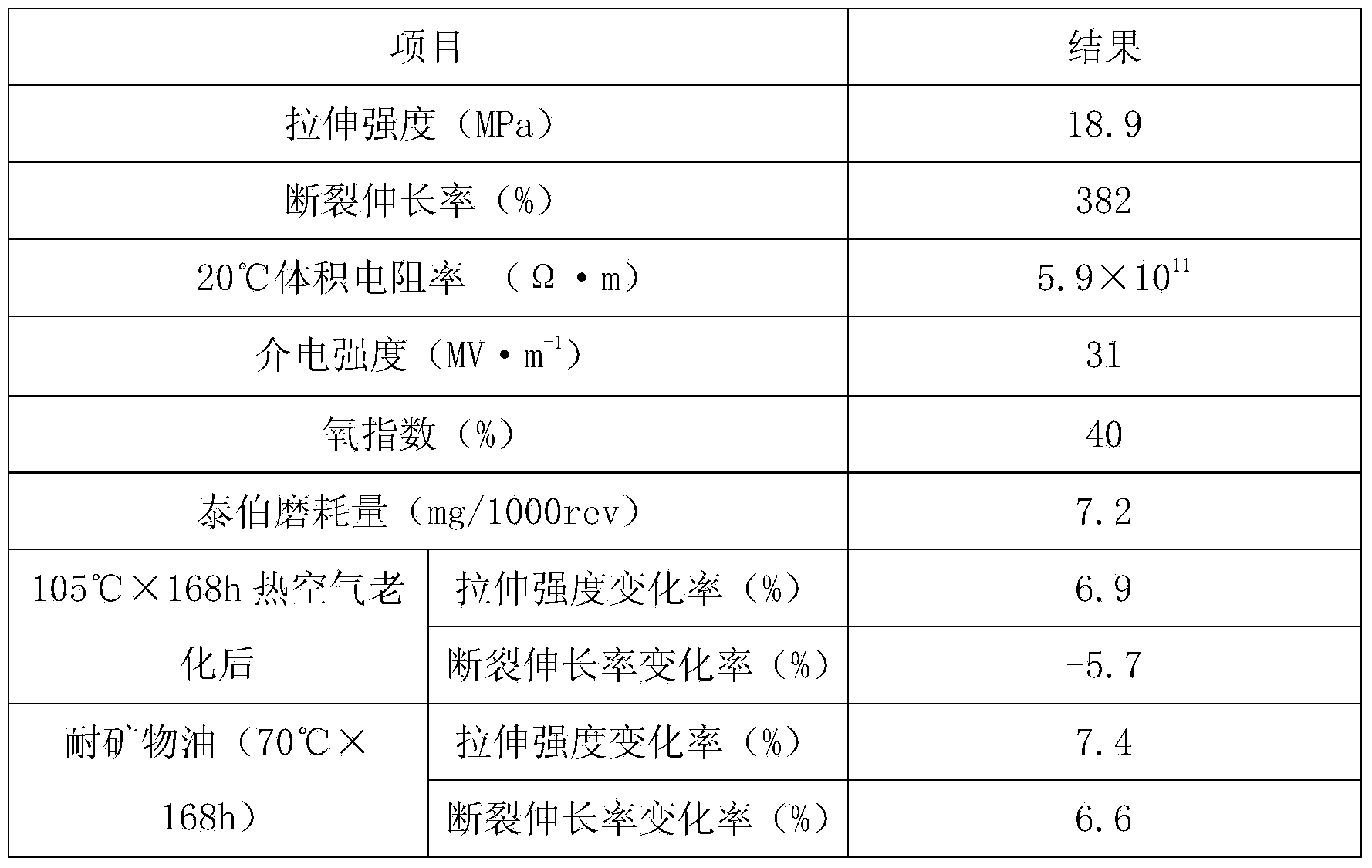

[0012] The material of the outer sheath 10 is made of the following raw materials in parts by weight: methyl vinyl phenyl silicone rubber 62, butadiene-vinyl pyridine rubber 38, acrylate rubber 24, coumaron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com