Repeatable fuse for high current

A self-resetting, high-current technology, applied to circuits, resistors, electric switches, etc., can solve problems such as electrical and electronic product circuit overheating, electrical and electronic product fires, self-resetting fuse abnormalities, etc., to prevent fires or failures Effects of minimizing and suppressing fire or failure and suppressing overheating of circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

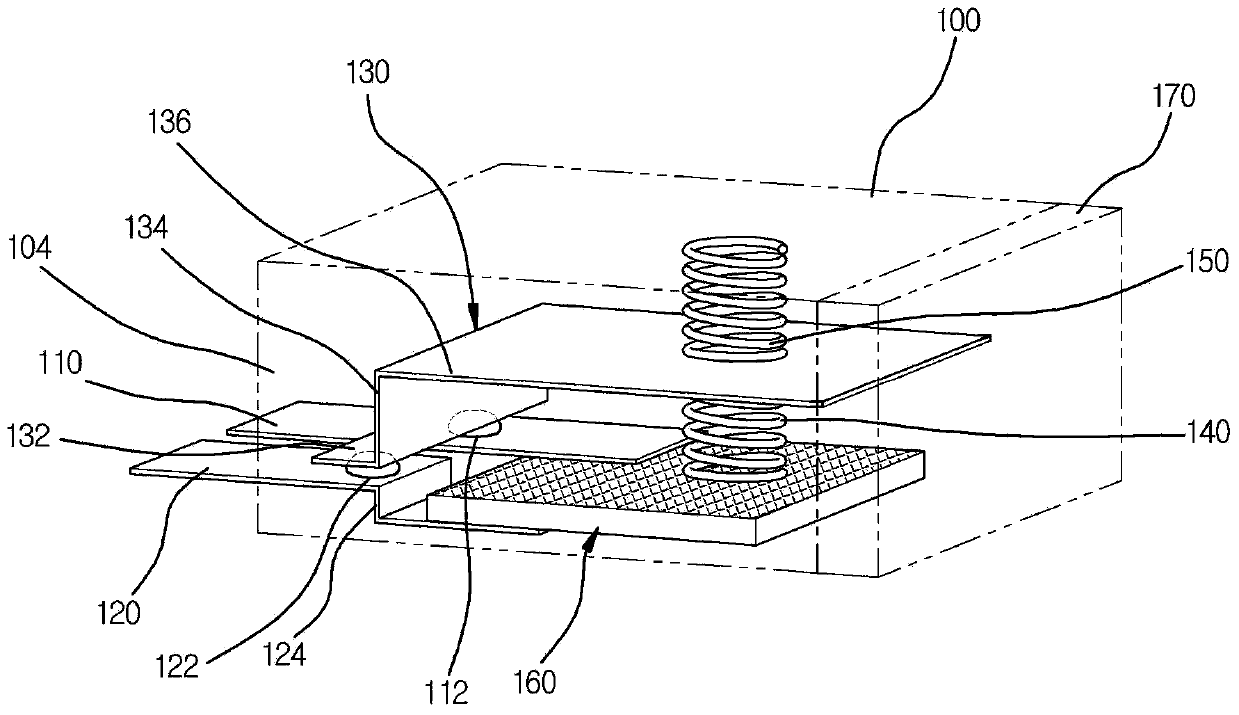

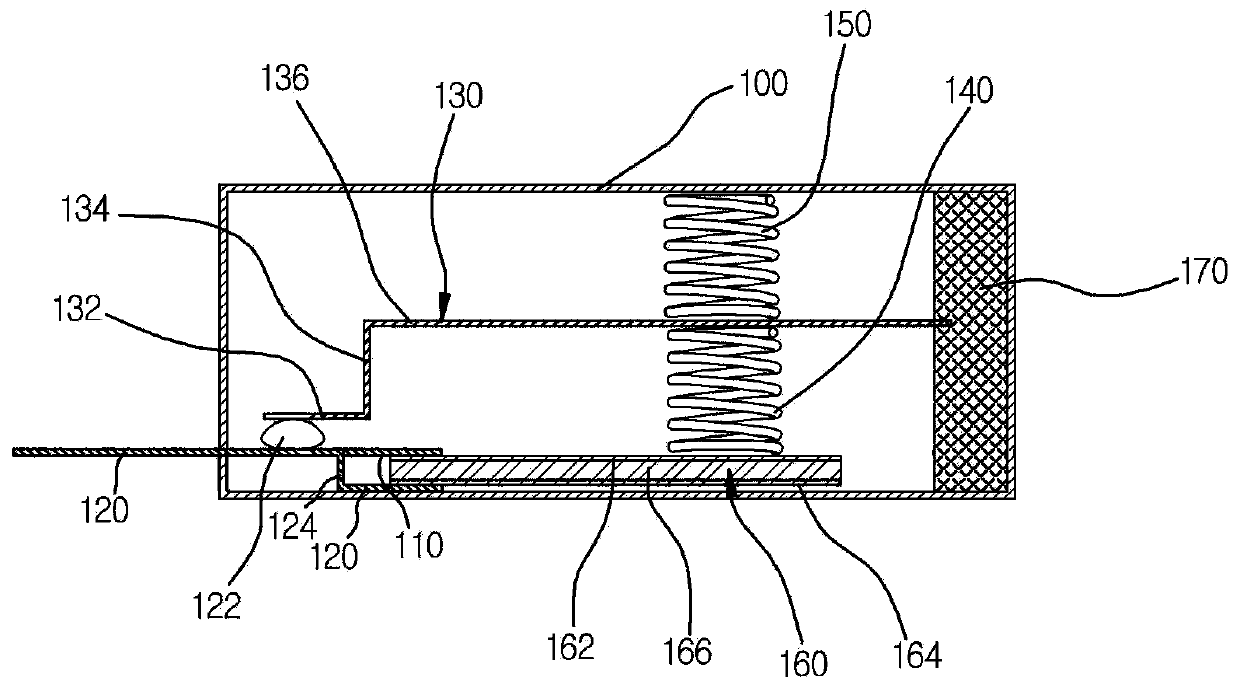

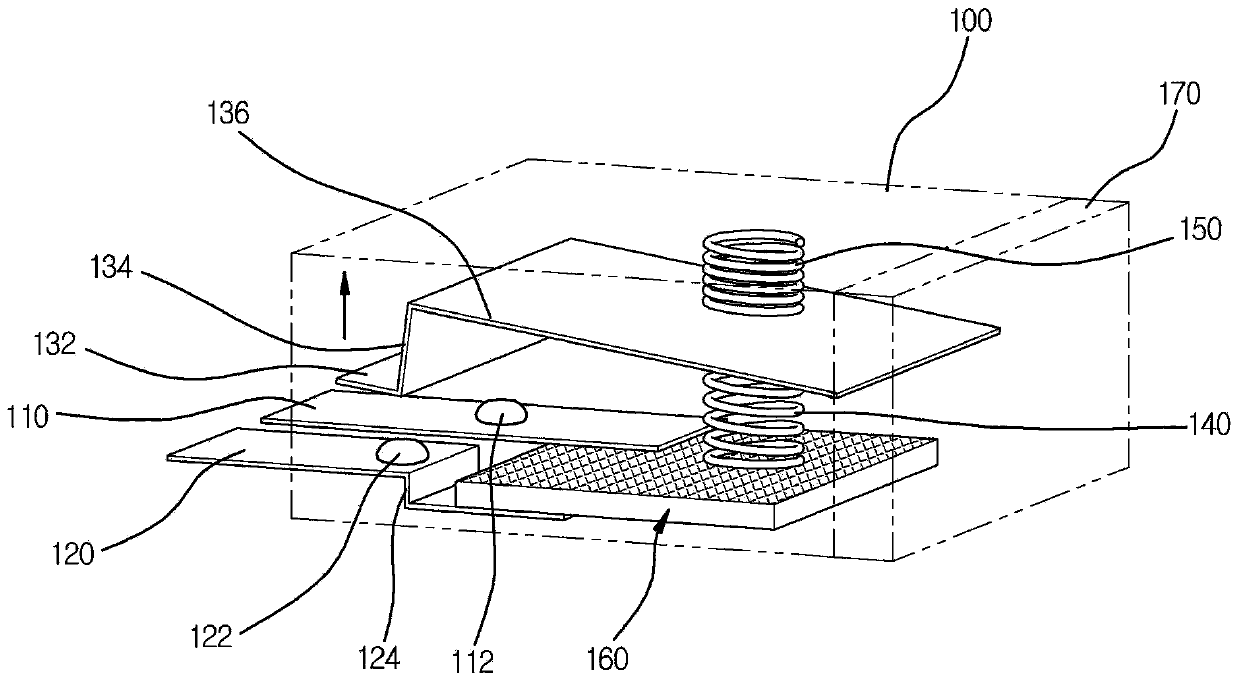

[0104] figure 1 A diagram schematically showing a self-resetting fuse for large current according to a first embodiment of the present invention, figure 2 for schematic representation figure 1 The cross-sectional view of a self-resetting fuse for high current, image 3 for expressing in figure 1 A diagram of the situation where the first lead terminal and the second lead terminal are electrically disconnected in a self-resetting fuse for high current, Figure 4 is a diagram showing an example of a positive temperature coefficient thermistor (positive temperaturecoefficient thermistor), Figure 5 This is a graph showing the resistance characteristics of a positive temperature coefficient thermistor based on temperature.

[0105] refer to Figure 1 to Figure 5 , according to the first embodiment of the present invention, the self-resetting fuse for large current includes: a casing 100 having an inner space; a first lead terminal 110 disposed on a first side surface of the ...

Embodiment 2

[0151] Figure 6 is a diagram schematically showing a resettable fuse for large current according to the second embodiment, Figure 7 for schematic representation Figure 6 The cross-sectional view of a self-resetting fuse for high current, Figure 8 for expressing in Figure 6 A diagram of the situation where the first lead terminal and the second lead terminal of the high current self-resetting fuse are electrically disconnected. In the following examples, descriptions of parts that overlap with those described in Example 1 are omitted as much as possible.

[0152] refer to Figure 6 to Figure 8 The resettable fuse for large current includes a trigger terminal 180 disposed on the second side surface of the housing 100 . The trigger terminal 180 is positioned by being inserted through the second side of the case 100, and may be formed of a conductive material. The trigger terminal 180 is configured to be connected to the positive temperature coefficient thermistor 160 ,...

Embodiment 3

[0163] Figure 9 is a diagram schematically showing a resettable fuse for large current according to the third embodiment, Figure 10 for schematic representation Figure 9 A cross-sectional view of a self-resetting fuse for high current.

[0164] refer to Figure 9 to Figure 10 , in the self-resetting fuse for large current, the main spring 140 and the bias spring 150 are configured to be able to expand or compress in a direction parallel to the direction in which the connecting portion 132 of the contact operating plate 130 moves, and the main spring 140 is arranged between the positive temperature coefficient thermistor 160 and the first plate portion 136, and the bias spring 150 is arranged on the contact operation plate 130 on the opposite side to the side where the main spring 140 is arranged based on the first connecting portion 134. between the connecting portion 132 and the inner wall of the casing 100 . The connection part 132 of the contact operation plate 130 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com