Green tea and its preparation process

A preparation process and technology for green tea, applied in the field of green tea and preparation thereof, can solve the problems of steamed green tea with a dull aroma, easily destroying chlorophyll, unclear soup color and the like, and achieves maintaining the appearance and color, the tea soup is light green, and the color is dark green. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

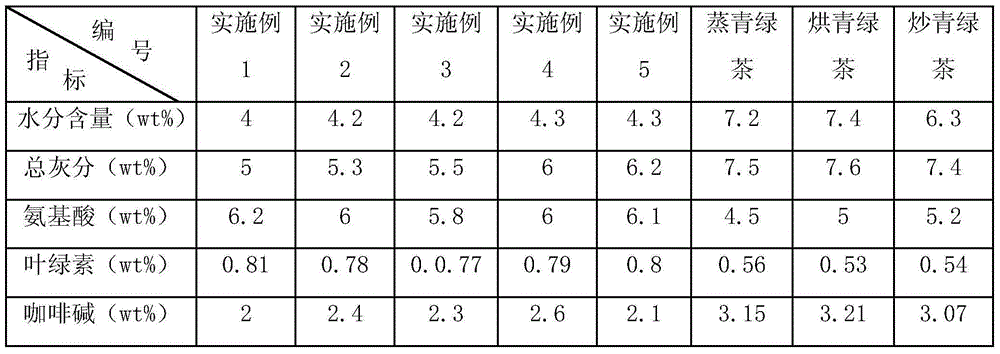

Examples

Embodiment 1

[0085] The preparation of embodiment 1 green tea of the present invention

[0086] A. Weigh 6.5kg of tea leaves, steam the tea greens, control the steam flow to 140kg / h, steam temperature to 100°C, and steam the greens for 80s;

[0087] B. Air-cool the steamed tea leaves to 30°C, and beat the leaves after the air-cooling. The temperature of the hot air is 100°C when the leaves are beaten, the temperature of the tea leaves is controlled at 36°C, and the leaf-beating time is 16 minutes;

[0088] C. Roughly knead the tea leaves after the leaves are beaten for the first time. During the first rough kneading, the hot air is passed. The temperature of the hot air is 90°C. The spindle speed of the rough kneading machine is 35r / min. 16 minutes; after the first rough kneading is completed, the second rough kneading is carried out after 40 seconds. During the second rough kneading, the hot air is turned on. The temperature of the hot air is 80°C. At 36°C, the rough kneading time is 1...

Embodiment 2

[0092] The preparation of embodiment 2 green tea of the present invention

[0093] A. Weigh 6.5kg of tea leaves, steam the tea greens, control the steam flow to 120kg / h, steam temperature to 90°C, and steam the greens for 70s;

[0094] B. Air-cool the steamed tea leaves to 42°C. After the air-cooling, beat the leaves. The temperature of the hot air is 90°C when the leaves are beaten. The temperature of the tea leaves is controlled at 34°C. The time for beating the leaves is 18 minutes;

[0095] C. Roughly knead the leaves after the leaves have been beaten for the first time. During the first rough kneading, the hot air is passed. The temperature of the hot air is 85°C, the temperature of the tea leaves is controlled at 34°C, the spindle speed of the rough kneading machine is 35r / min, and the rough kneading time 18 minutes; after the first rough kneading is completed, the second rough kneading is carried out after 60 seconds. During the second rough kneading, the hot air is tur...

Embodiment 3

[0099] The preparation of embodiment 3 green tea of the present invention

[0100] A. Weigh 7.5kg of tea leaves, steam the tea greens, control the steam flow to 120kg / h, steam temperature to 100°C, and steam the greens for 90s;

[0101] B. Air-cool the steamed tea leaves to 38°C. After the air-cooling, beat the leaves. The temperature of the hot air is 100°C when the leaves are beaten. The temperature of the tea leaves is controlled at 38°C. The time for beating the leaves is 16 minutes;

[0102] C. Roughly knead the tea leaves after the leaves are beaten for the first time. During the first rough kneading, the hot air is passed through. The temperature of the hot air is 95°C. The spindle speed of the rough kneading machine is 35r / min. 16 minutes; after the first rough kneading is completed, the second rough kneading is carried out after 50 seconds. During the second rough kneading, the hot air is turned on. The temperature of the hot air is 90°C. At 34°C, the rough kneadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com