Detaching and recovery processing integrated machine and recovery processing method for waste motor

A technology of recycling and integrated machine, which is applied in the field of waste motor dismantling, recycling, and processing integrated machine and recycling process, which can solve the problems of inconvenient dismantling, unfavorable copper recycling, labor-intensive and time-consuming, etc., and achieves a simple dismantling method Scientific, improved dismantling status, good cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

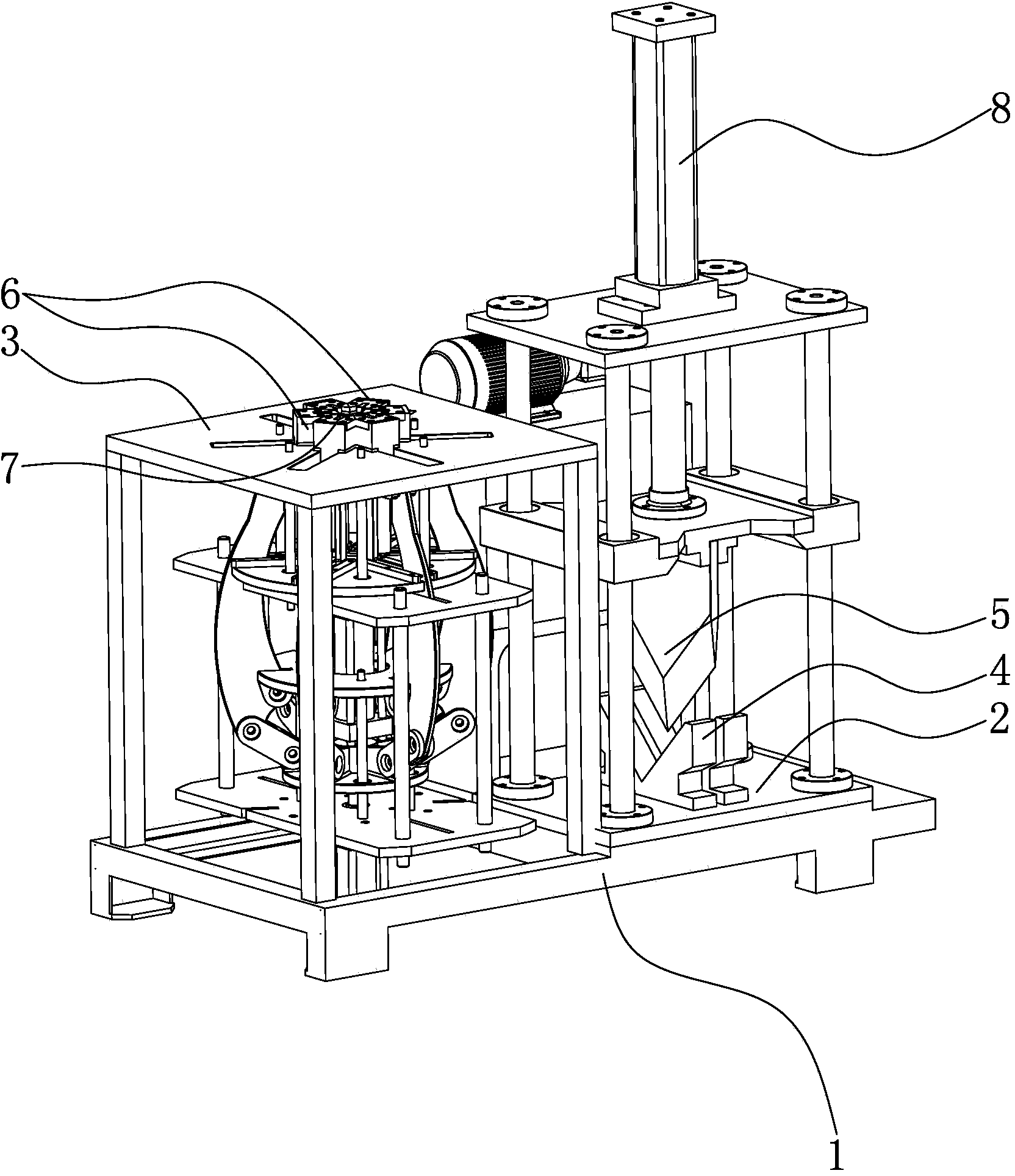

[0026] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 -5:

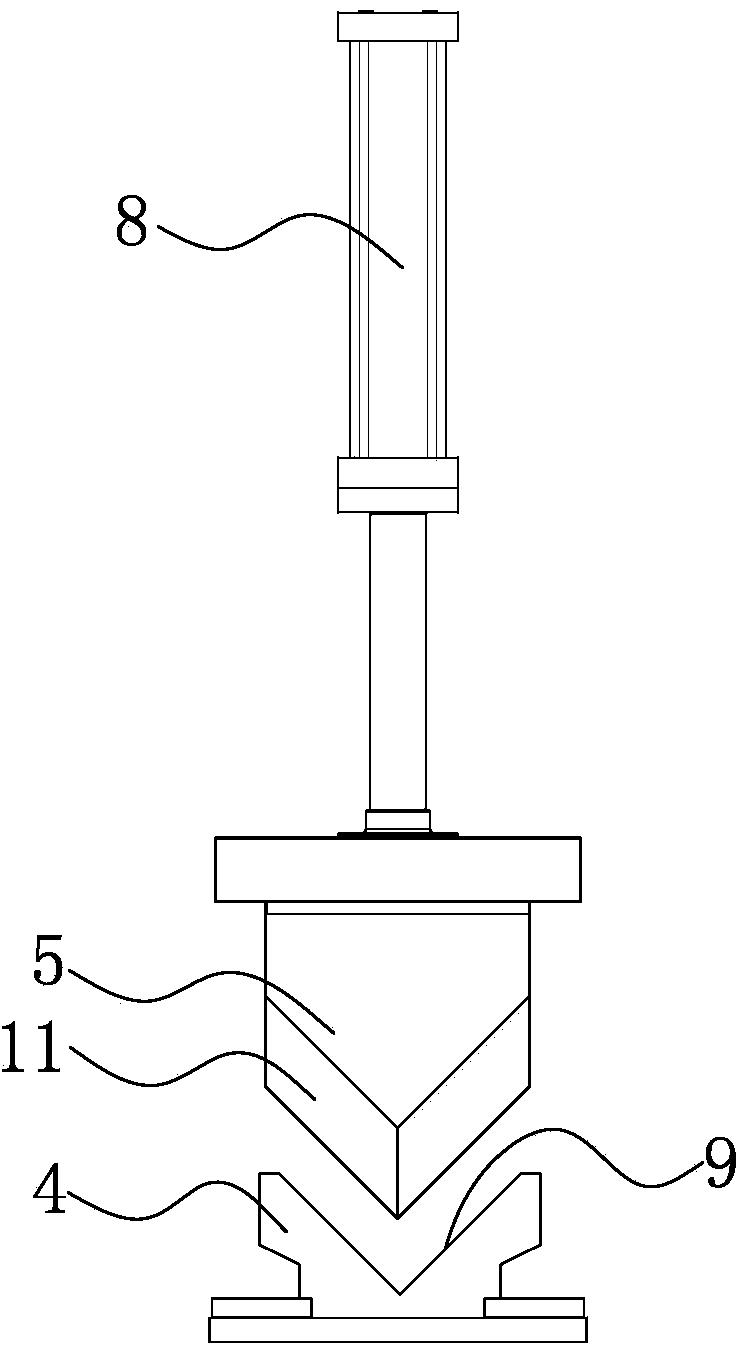

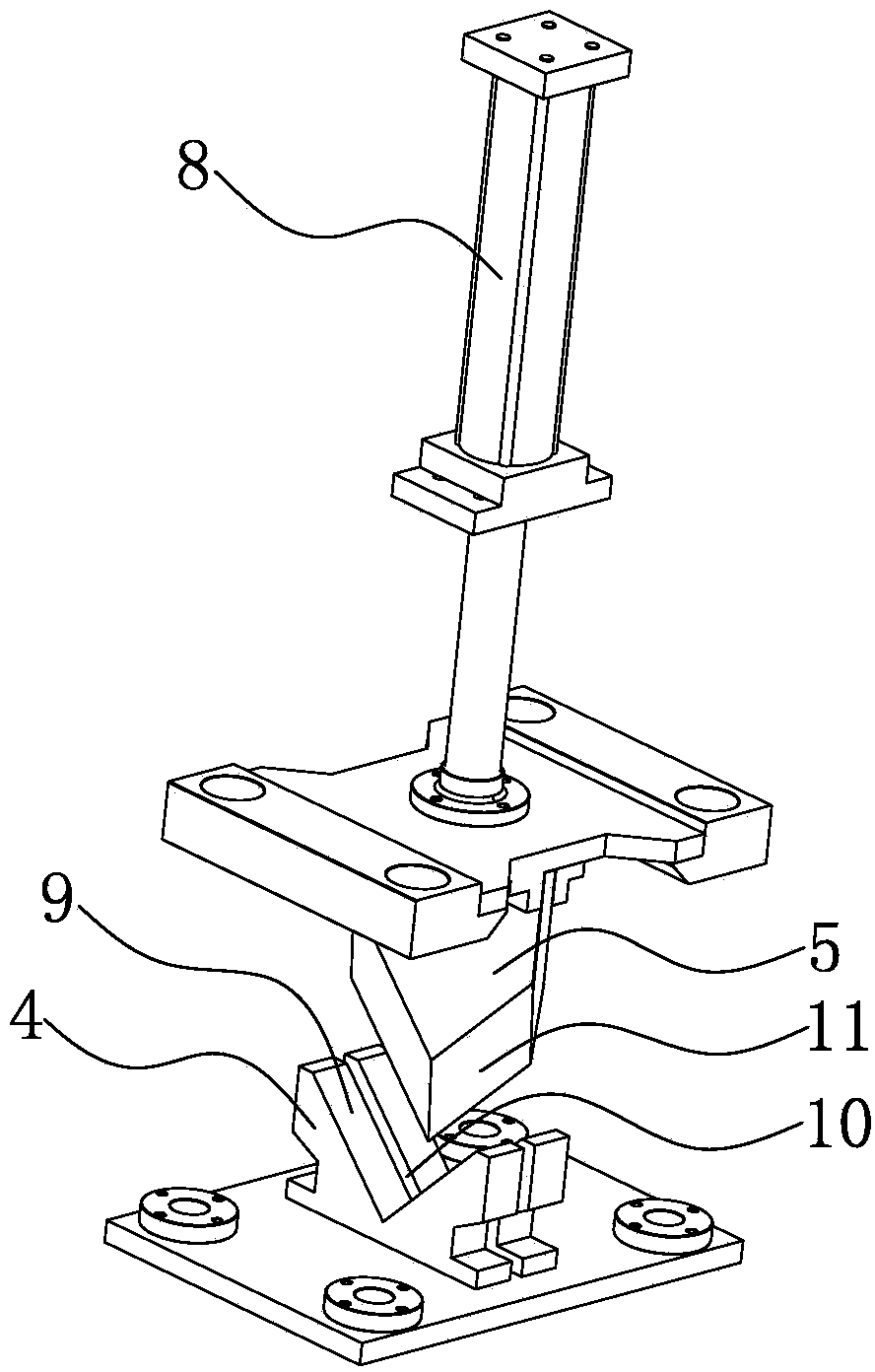

[0027] An all-in-one machine for dismantling and recycling waste motors, comprising a frame 1, a cutting platform 2 and a dismantling platform 3 are provided on the frame, and a motor stator fixing seat 4 is detachably provided on the cutting platform, A cutting knife 5 controlled by a driver 8 is arranged above the cutting platform, and several jaws 6 are arranged around the center of the dismantling platform on the dismantling platform, and the several jaws are driven by the driving mechanism and can be disassembled. Move and gather the clamped objects on the platform or move and disperse them. The motor stator thimbles 7 driven by the driver are all provided on the several jaws.

[0028] The fixed seat of the motor stator is provided with a "V" shaped groove 9, and the groove bottom of the groove is provided with a blade groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com