Tweezers

A technology of tweezers and clamping arms, applied in the field of tweezers, can solve problems such as laborious fingers, high manufacturing process requirements, and shortened service life, so as to achieve the effects of no degradation in blade performance, avoiding structural instability, and avoiding operational errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

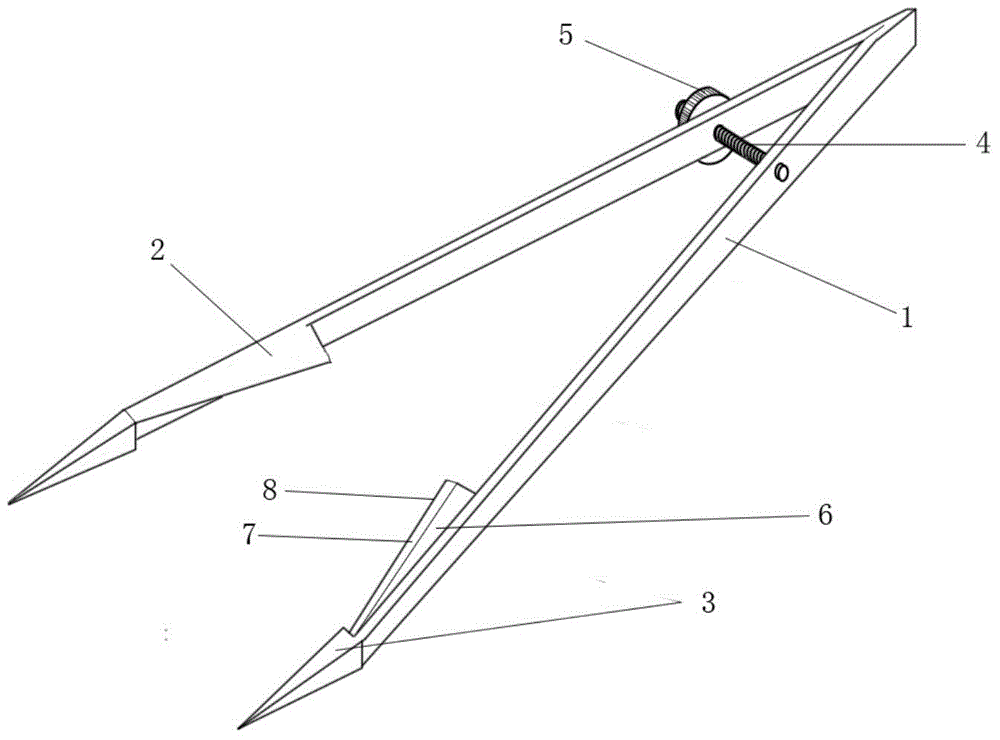

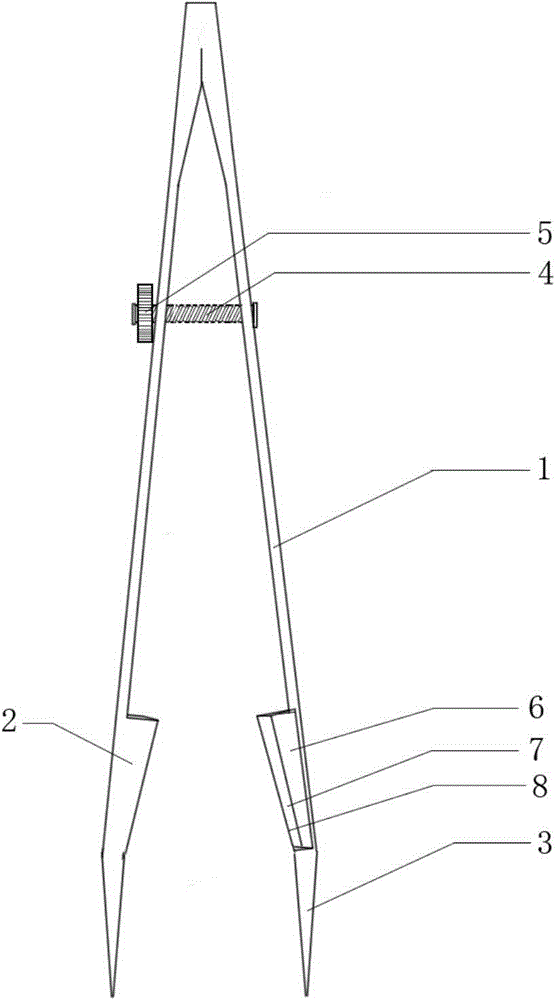

[0020] Such as Figures 1 to 4 As shown, the tweezers of the present invention include two clamping arms 1 and clamping ends 3, the ends of the clamping arms are connected to the clamping ends, a pair of blades 2 that are staggered and tangent are arranged at the ends of the two clamping arms, and the joints near the head ends of the two clamping arms are provided. There is an adjustment rotating shaft 4 that runs through the two clamping arms.

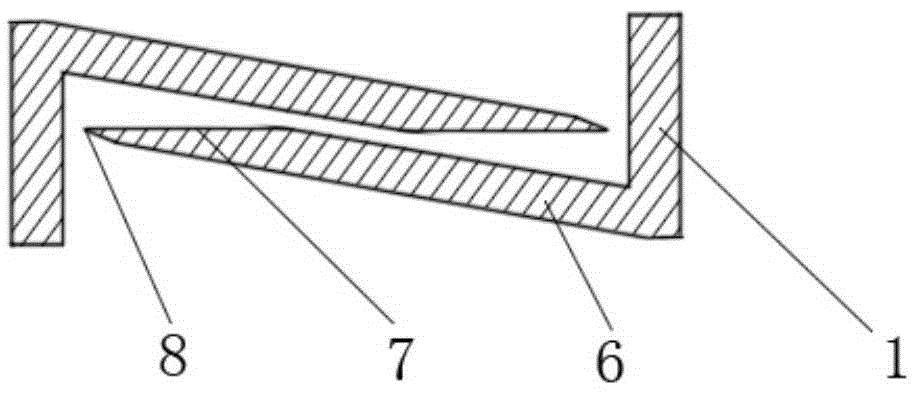

[0021] The pair of blades and the two clamping arms are integrally formed by extending, bending and flattening the ends of the two clamping arms inwardly. When the clamping arms are opened and closed, the cutting edges of the two blades form a notch with each other. The blade 2 is composed of the extension part 6 of the clamp arm, the cutting plane 7 and the cutting edge 8 of the blade. The angle between the extension part of the clamp arm and the clamp arm is 60-80 degrees. The arm extension forms the facet, and the edge of the face...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com