Method for preparing low calcium and magnesium refined salt by downhole denitration process

A denitrification and process technology, applied in the direction of alkali metal chloride, etc., can solve the problems of reducing the discharge of salt-making mother liquor, large investment in equipment, high purification cost, etc., and achieve the effect of resolving brine turbidity, low content, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

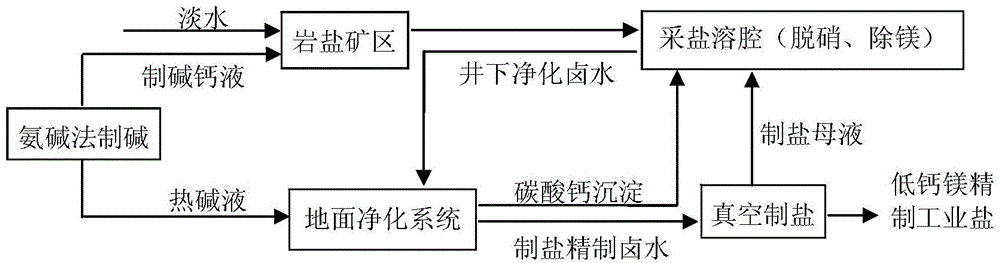

[0048] A method for preparing low-calcium magnesium refined industrial salt by using the downhole denitrification process: such as figure 1 As shown, the alkali-making calcium solution (CaCl 2 110g / l, pH 13) Add appropriate amount of fresh water, control the blending ratio to 1:11, that is, mix 1 part of alkali-making calcium solution with 11 parts of fresh water (the pH of the mixed solution is about 12), and inject it into the underground of the salt mine. Dissolve rock salt in the mine, and after 3 days of settlement, the NaCl content is 290-300g / l, and the NaCl content is 290-300g / l. 2 SO 4 Content about 10g / l, CaSO 4 Low-nitrate brine with a content of 2.5-2.7g / l; transport the mined low-nitrate brine to the inclined plate settler, add 18% alkali-making hot lye to adjust the pH to 9, and react with calcium sulfate in the low-nitrate brine After the calcium ion content in the detected brine is lower than 5mg / l, it is transferred to the inclined tube sedimentation tank, ...

Embodiment 2

[0051] A method for preparing low-calcium magnesium refined industrial salt by using the downhole denitrification process: such as figure 1 As shown, the alkali-making calcium solution (CaCl 2 110g / l, pH 12) Add a certain amount of fresh water, control the blending ratio to 1:18.2, that is, mix 1 part of alkali-making calcium solution with 18.2 parts of fresh water (the pH of the mixed solution is about 11), and inject it into the underground of the salt mine , Dissolve rock salt in the mine, and after 5 days of settlement, the NaCl content is 295-305g / l, and the NaCl content is 295-305g / l.2 SO 4 Content 15g / l, CaSO 4 Low-nitrate brine with a content of 1.8-2.0g / l; transport the mined low-nitrate brine to the inclined plate settler, add 20% alkali-making hot lye to adjust the pH to 9.5, and react with calcium sulfate in the low-nitrate brine After detecting that the calcium ion content in the brine is lower than 4mg / l, it is transferred to the inclined tube sedimentation tan...

Embodiment 3

[0053] A method for preparing low-calcium magnesium refined industrial salt by using the downhole denitrification process: such as figure 1 As shown, the alkali-making calcium solution (CaCl 2 120g / l, pH 13) Add a certain amount of fresh water, and control the blending ratio to 1:9.3, that is, mix 1 part of alkali-making calcium solution with 9.3 parts of fresh water (the pH of the mixed solution is about 12), and then inject it into the underground of the salt mine , Dissolve rock salt in the mine, and after 4 days of settlement, the NaCl content is 300-310g / l, and the NaCl content is 300-310g / l. 2 SO 4 Content 7g / l, CaSO 4 Low-nitrate brine with a content of 2.6-2.8g / l; transport the mined low-nitrate brine to the inclined plate settler, add 22% alkali-making hot lye to adjust the pH to 10.5, and react with calcium sulfate in the low-nitrate brine After detecting that the calcium ion content in the brine is lower than 3.5mg / l, it is transferred to the inclined tube sedime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com