A kind of preparation method of magnetic agarose microsphere

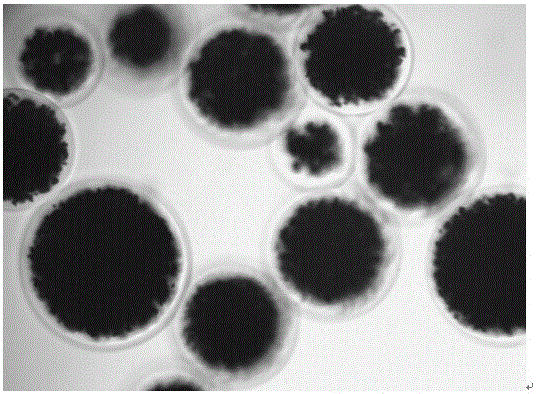

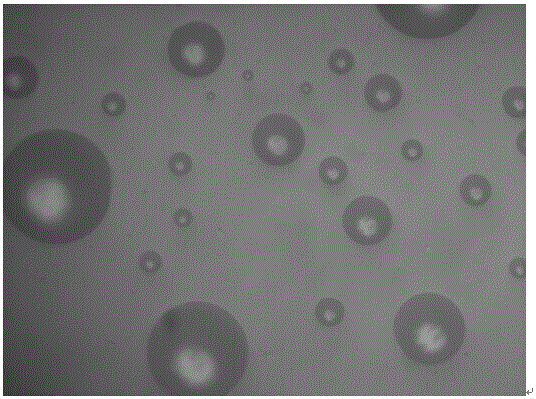

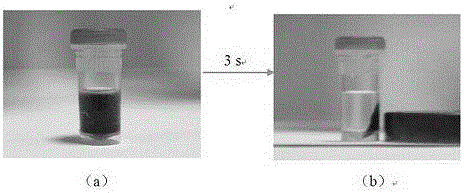

A technology of agarose microspheres and agarose, which is applied in the field of preparation of magnetic agarose microspheres, can solve the problems of uneven coating of magnetic agarose microspheres, low separation and purification, and poor magnetic response, and achieve smooth ball formation , Good dispersibility, and the effect of improving the coating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] 1. the preparation method of a kind of agarose nonmagnetic microsphere of the present invention, comprises the following steps:

[0035] (1) Provide agarose aqueous solution containing one or several additives as the water phase W, and heat at a certain temperature to dissolve the agarose.

[0036] (2) Provide one or several organic solvents that are immiscible with the water phase as the oil phase O, and dissolve one or several emulsifiers in it. Heat and stir the oil phase O at a constant temperature and constant speed, add the water phase W to the oil phase O in a certain proportion, and mechanically stir the reaction at a certain speed for a certain period of time to obtain a W / O emulsion.

[0037] (3) Rapidly lower the W / O emulsion to a certain temperature to form agarose microspheres.

[0038] More specifically, in step (1), the agarose aqueous solution provided has a preset concentration, and the agarose-containing aqueous solution will be used as the aqueous ph...

Embodiment 1

[0059] 1. Preparation of non-magnetic agarose microspheres:

[0060] (1) Add 2.0 g of agarose microspheres to 100 ml of ultrapure water and heat at 100°C to prepare the agarose aqueous phase W.

[0061] (2) Add 180ml of liquid paraffin, 40ml of petroleum ether, add 8.0g of emulsifier Span 80, and fully disperse to prepare oil phase O.

[0062] (3) The oil phase O was heated at a constant temperature of 80°C, mechanically stirred at 400 rpm, and the water phase was quickly transferred in, and reacted for 3 hours.

[0063] (4) Cool the ice water bath to 15°C rapidly.

[0064] 2. Activation and cross-linking of non-magnetic agarose microspheres:

[0065] (1) Take 5g of microspheres, add 7.5ml of 0.8mol / L NaOH, 0.01g of sodium borohydride, shake at 25°C and 400rpm for 30min.

[0066] (2) Add 7.5ml of dimethyl sulfoxide and 3.75ml of epichlorohydrin to the above solution. React at a constant temperature of 30°C and 400rpm for 20h.

[0067] (3) Wash to remove unreacted reagents...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com