Low-cost Mo-free plastic mould steel plate and production technology thereof

A technology of plastic mold steel and production process, applied in the field of plastic mold steel, can solve the problems of low production efficiency, long production cycle, rising production cost, etc., and achieve the effect of short production cycle, low alloy cost and large process window.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The steel is composed of the following components (wt%): C: 0.39%, Si: 0.30%, Mn: 0.58%, P≤0.020%, S≤0.010%, Cr: 1.25~1.55%, Nb: 0~0.015% , B: 0.0020%, the rest is Fe and unavoidable impurities, wherein Cr / Mn is 2.1-2.6, and Si+Cr+Mn is 2.1%-2.4%.

[0031] (1) according to above-mentioned chemical composition weight percent, carry out smelting with 180 tons of converters, continuous casting becomes the continuous casting slab of 220mm;

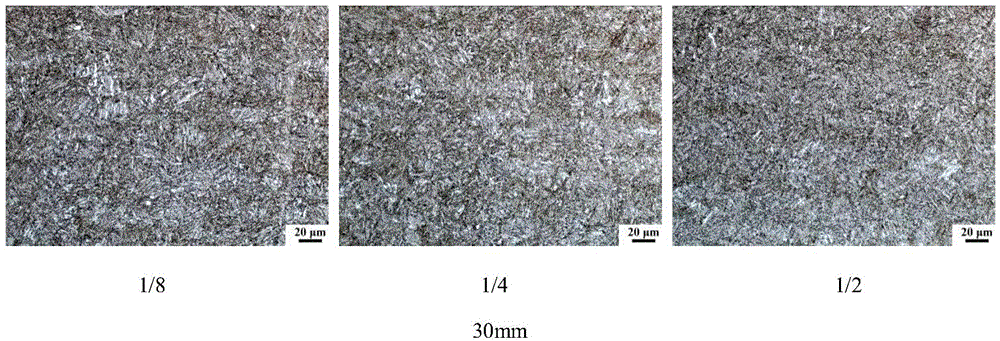

[0032] (2) In the heating process, the continuous casting slab is heated at a temperature of 1170-1210°C, and the heating method is heated to 800°C at a speed of 10-20°C / min, and then kept at a temperature of 15 minutes. Continue heating, and heat up at a speed of ≤5°C / min Keep warm at 1170-1210°C for 60-90 minutes, and roll the soaked slab into a 30mm thick plate by hot rolling on a 5m wide plate rolling mill;

[0033] (3) In the hot rolling process, the hot rolling temperature is 980 ~ 1120 ℃, the pass deformation rate? 15%; after r...

Embodiment 2

[0036] The steel is composed of the following components C: 0.39%, Si: 0.30%, Mn: 0.58%, P≤0.020%, S≤0.010%, Cr: 1.25~1.55%, Nb: 0~0.015%, B: 0.0020% , and the rest are Fe and unavoidable impurities, among which Cr / Mn is 2.1-2.6, and Si+Cr+Mn is 2.1%-2.4%.

[0037] (1) according to above-mentioned chemical composition weight percent, carry out smelting with 180 tons of converters, continuous casting becomes the continuous casting slab of 220mm;

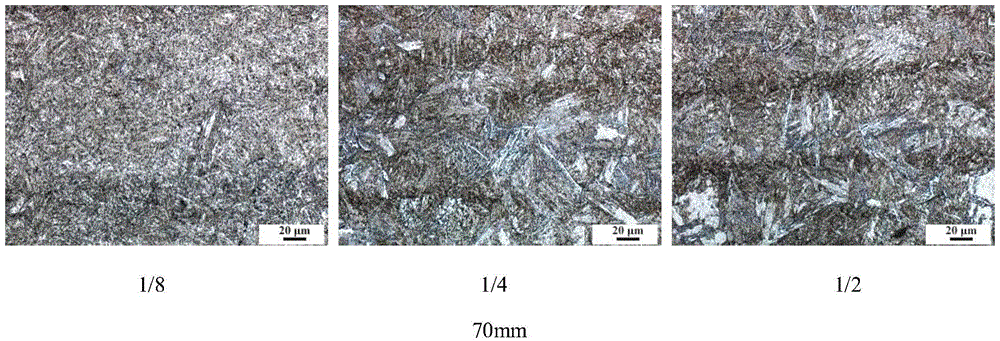

[0038] (2) In the heating process, the continuous casting slab is heated at a temperature of 1170-1210°C, and the heating method is heated to 800°C at a speed of 10-20°C / min, and then kept at a temperature of 15 minutes. Continue heating, and heat up at a speed of ≤5°C / min Keep warm at 1170-1210°C for 60-90 minutes, and roll the soaked slab into a 70mm thick plate by hot rolling on a 5m wide plate rolling mill;

[0039] (3) In the hot rolling process, the hot rolling temperature is 980 ~ 1120 ℃, the pass deformation rate? 15%; after...

Embodiment 3

[0042] The steel is composed of the following components (wt%): C: 0.39%, Si: 0.30%, Mn: 0.58%, P≤0.020%, S≤0.010%, Cr: 1.25~1.55%, Nb: 0~0.015% , B: 0.0020%, the rest is Fe and unavoidable impurities, wherein Cr / Mn is 2.1-2.6, and Si+Cr+Mn is 2.1%-2.4%.

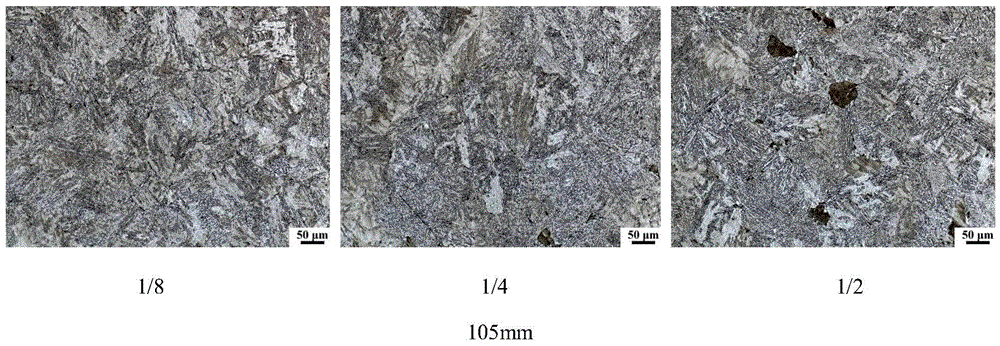

[0043] (1) according to the chemical composition weight percentage described in claim 1, smelting is carried out with 180 tons of converters, and continuous casting becomes the thick continuous casting slab of 320mm;

[0044] (2) In the heating process, the heating temperature of the continuous casting slab is 1170-1210°C, and the heating method is heated to 800°C at a speed of 10-20°C / min, and then kept for 30 minutes, and the heating is continued, and the temperature is raised at a speed of ≤10°C / min Keep warm at 1170-1210°C for 60-90 minutes, and roll the soaked slab into a 105mm thick plate by hot rolling on a 5m wide plate rolling mill;

[0045] (3) In the hot rolling process, the hot rolling temperature is 980 ~ 1120 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com