Hot rolling flat steel for high toughness X80 elbow and production method thereof

A production method and high-toughness technology, which are used in hot-simmering elbow oil and gas transportation pipelines, hot-rolled flat steel for high-toughness X80 elbows and their production fields, can solve the problem of inability to form commercial production, high production costs, and insufficient toughness. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

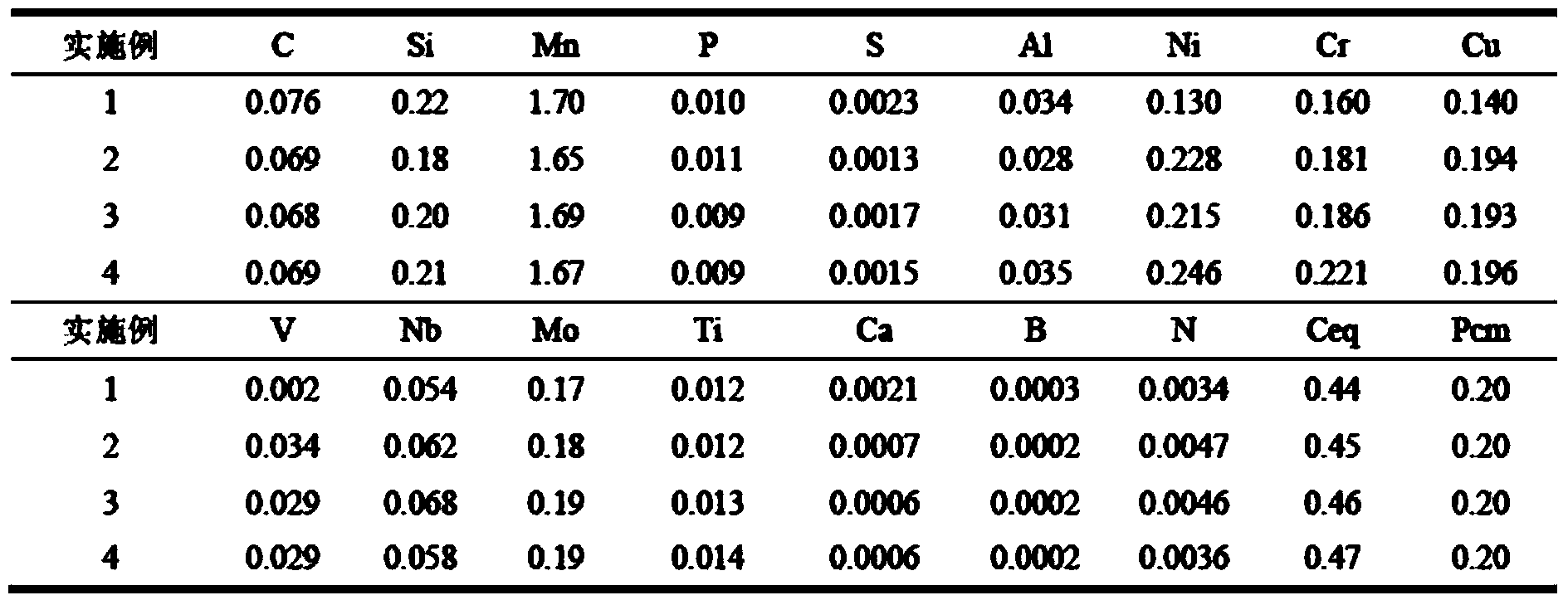

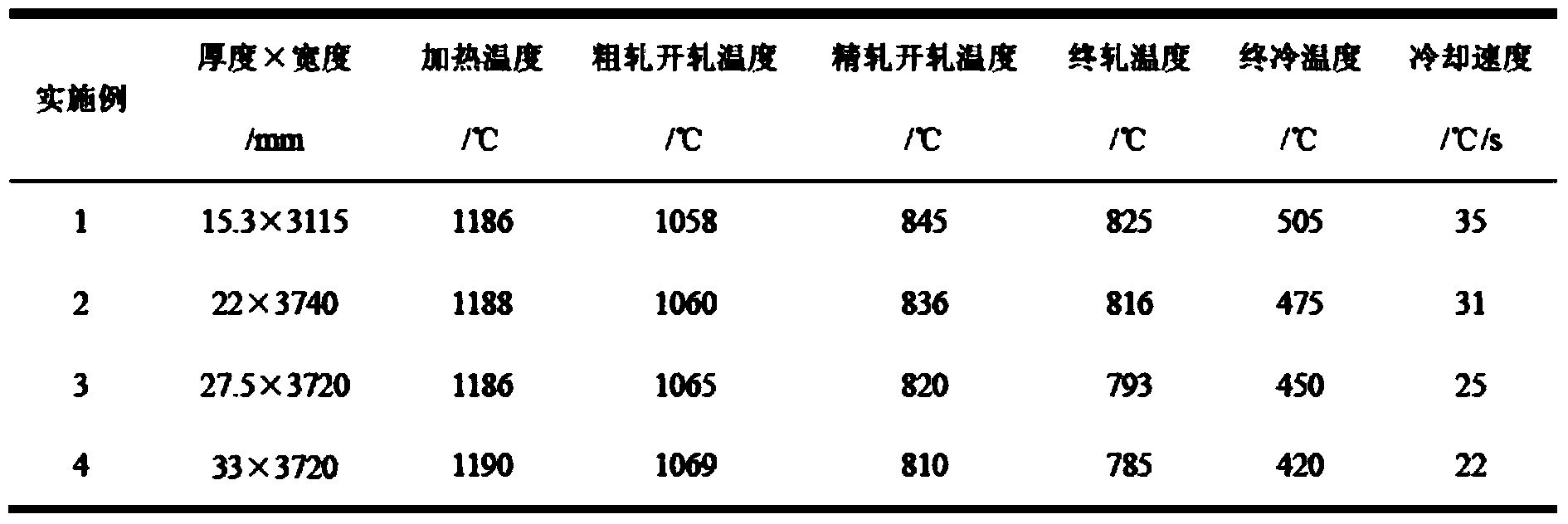

[0031] According to the composition design and production method provided by the present invention, 300 and 400mm continuous casting slabs are smelted on a 100-ton converter, and steel plates are rolled in a 4300mm wide and thick plate rolling mill. The chemical composition is shown in Table 1, and the rolling process parameters are shown in Table 2. Hot rolling The performance of the steel plate is shown in Table 3, and the performance of the bent pipe after simmering is shown in Table 4.

[0032] Table 1 Chemical composition wt% of high toughness X80 bent pipe steel plate

[0033]

[0034] Table 2 Heating, rolling and water cooling process parameters of high toughness X80 bent pipe steel plate

[0035]

[0036] Table 3 Performance of high toughness X80 bent pipe steel plate

[0037]

[0038] Table 4 Performance of high toughness X80 elbow after simmering

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com