Dual-channel nozzle structure capable of controlling reactant uniform distribution

A uniformly distributed, dual-channel technology, applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve the problems affecting the quality of crystal growth, and it is difficult to overcome the uneven distribution of precursors, so as to improve the uniformity, Meet the effect of uniform growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

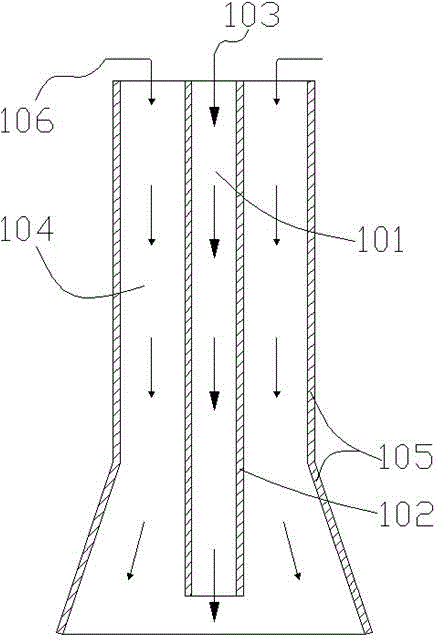

[0019] Such as figure 1 As shown, a dual-channel spout structure with controllable reactants evenly distributed in the present invention is mainly composed of an equal-diameter cylinder 102 and a variable-section outer sleeve 105; the outer sleeve 105 and the cylinder 102 are coaxial; The variable cross-section outer sleeve 105 includes an upper cylinder and a lower skirt body expansion section, the cross section of the skirt body expansion section gradually expands from top to bottom; the outer wall of the cylinder 102 and the inner wall of the variable cross-section outer sleeve 105 form a first channel 104, the reactant gas 106 passed into the first channel 104 is GaCl, the hollow part of the cylinder 102 is the second channel 101, and the gas 103 passed into the second channel 101 is GaCl and N 2 The mixed gas, adjust GaCl and N 2 The flow ratio of the gas in the second channel 101 and the gas flow in the first channel 104 optimizes the uniformity of the radial distributi...

Embodiment 2

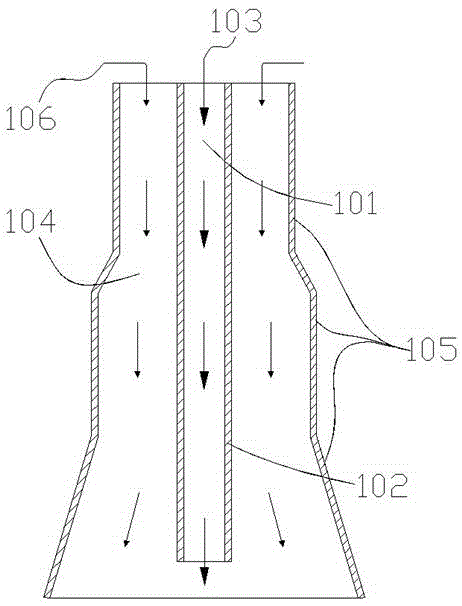

[0021] Such as figure 2 The shown dual-channel spout structure includes a first channel 104 and a second channel 101; the outer sleeve 105 of the first channel 104 is composed of four sections, which are sequentially from top to bottom, the first cylinder, the transition section, The second cylinder and skirt body expansion section, the cross-sectional circle diameters of each section increase from top to bottom, and the diameters of the joints of the sections are equal, and the gas 106 introduced into the channel 104 is GaCl; the second channel 101 Located at the center of the nozzle structure, the gas 103 introduced into the second channel 101 is N 2 ; Between the first channel 104 and the second channel 101 is a hollow cylinder 102 of equal diameter, whose length is slightly shorter than the length of the outer sleeve 105 . Adjusting the gas flow rate of the two channels can make the radial distribution of the reactant GaCl gas near the substrate to be grown more uniform,...

Embodiment 3

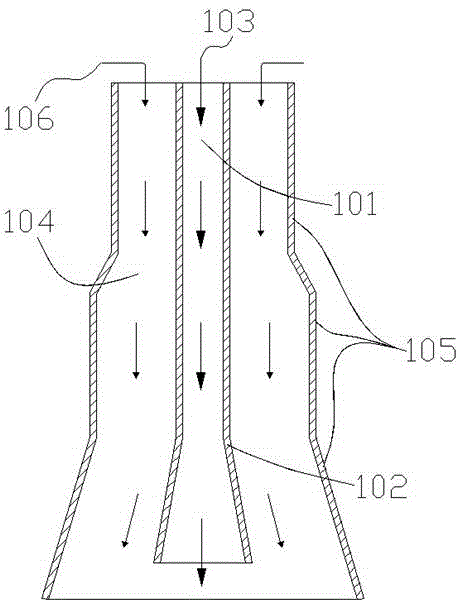

[0023] Such as image 3 The shown double-channel spout structure is based on the second embodiment, and the hollow cylinder 102 in the middle of the first channel 104 and the second channel 101 is improved. Here, the hollow cylinder 102 is composed of two sections, and its upper section is Equal-diameter hollow cylinder, the lower section of which is the skirt body. The extended section is a hollow circular platform tube, and the diameter of the junction of the two sections is equal; The expansion angles are consistent; the length of the hollow cylinder 102 is slightly shorter than the length of the outer sleeve 105 of the channel 104 . This structure further improves the uniformity of the radial distribution of the reactant GaCl gas near the upper substrate to be grown by adjusting the gas flow of the two channels, and can eliminate the problem that the growth thickness of the crystal produced by the traditional shower head system is thick in the middle and thin at the edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com