Polyamide 6 POY/FDY composite fibre and preparation method adopting spinning-interlacing one-step process

A composite fiber and polyamide technology, applied in the field of chemical fiber, to achieve the effect of large production capacity, reduced investment cost and good melt uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

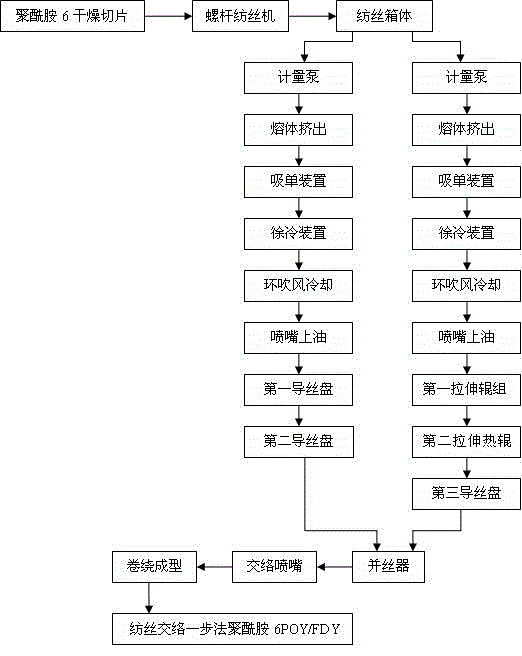

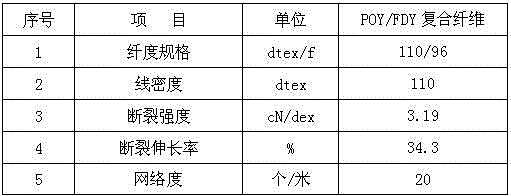

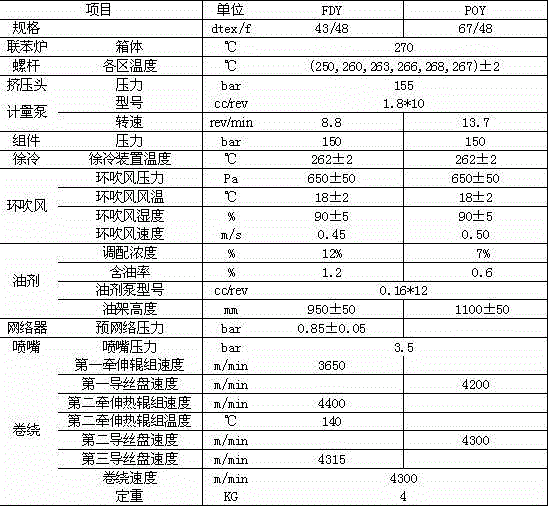

[0020] This example provides a method for preparing polyamide 6POY / FDY composite fiber by one-step spinning and interlacing of 110dtex / 96f (among them: 43dtex / 48f fully drawn yarn, 67dtex / 48f pre-oriented yarn). figure 1 . The production process is as follows:

[0021] The polyamide 6 dry chips that meet the requirements of the spinning process are input into the screw, heated, melted and filtered, and then enter the spinning box. The spinning melt is extruded from the micropores of two metering pumps, spinning components and two spinnerets, The slow cooling device and the surrounding air blowing cooling device are cooled and solidified to form two bundles of filaments, one of which is oiled through the nozzle, pre-networked, stretched and heat-set between the first drafting roller group and the second drafting hot roller group , and then pass through the third guide wire disc to obtain polyamide 6 fully drawn yarn (FDY); another bundle of yarn is oiled through the nozzle and...

Embodiment 2

[0027] This example provides a method for preparing polyamide 6POY / FDY composite fiber by one-step spinning and interlacing of 136dtex / 96f (including: 43dtex / 24f fully drawn yarn, 93dtex / 72f pre-oriented yarn). For the process flow, see the attached figure 1 . The production process is as follows:

[0028] The polyamide 6 dry chips that meet the requirements of the spinning process are input into the screw, heated, melted and filtered, and then enter the spinning box. The spinning melt is extruded from the micropores of two metering pumps, spinning components and two spinnerets, The slow cooling device and the surrounding air blowing cooling device are cooled and solidified to form two bundles of filaments, one of which is oiled through the nozzle, pre-networked, stretched and heat-set between the first drafting roller group and the second drafting hot roller group , and then pass through the third godet to obtain polyamide 6 fully drawn yarn (FDY); another bundle of yarn is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com