Blowing-suction machine with water piston

A blower and piston technology, applied to piston pumps, mechanical equipment, machines/engines, etc., can solve problems such as poor controllability, easy damage of gaskets, poor sealing effect, etc., to reduce manufacturing difficulty, cost, and precision Low requirements, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

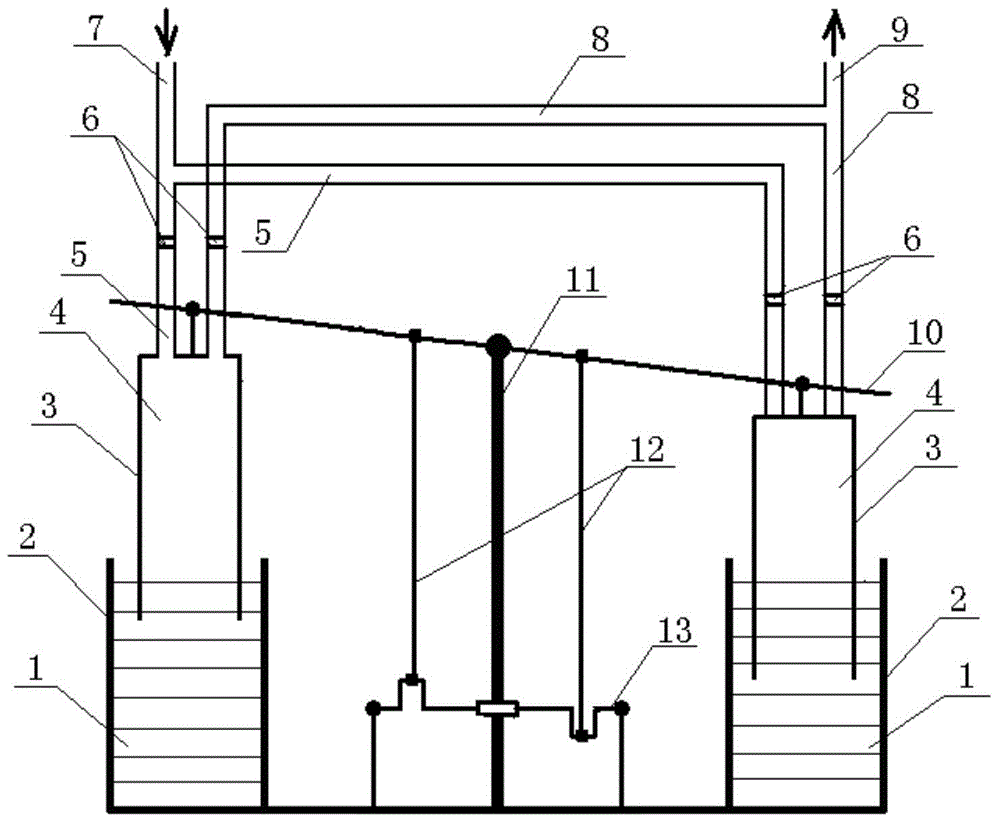

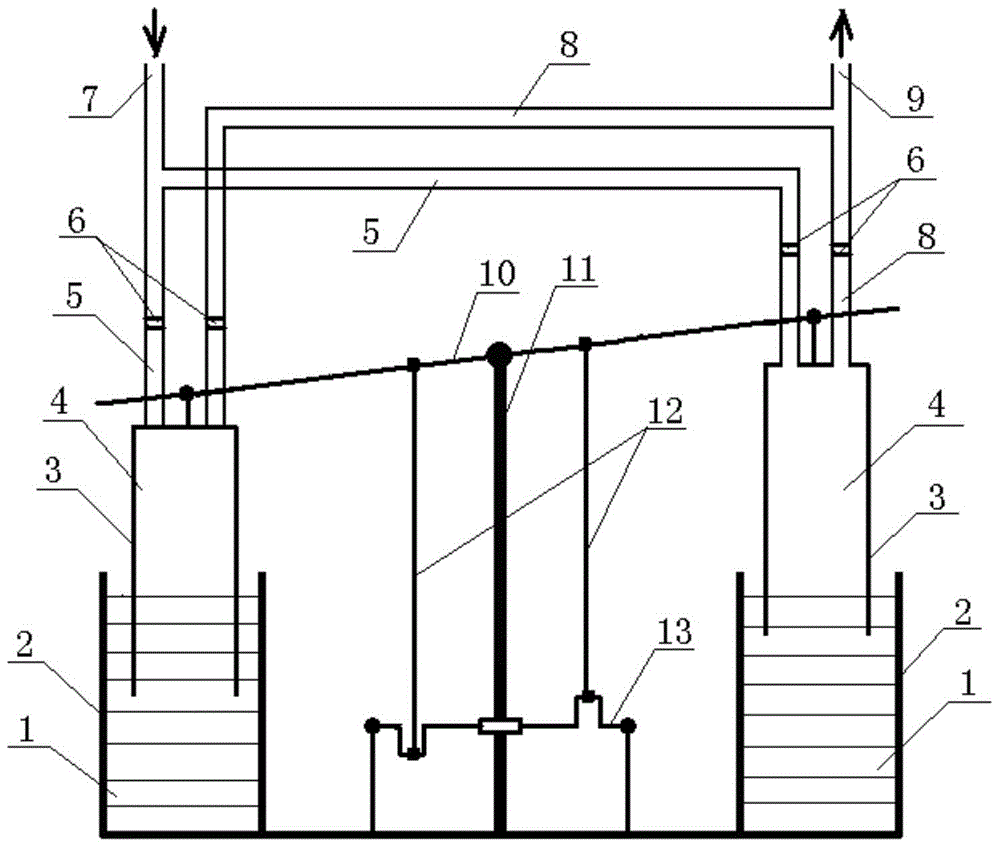

[0029] The present embodiment is a kind of water piston blower, such as figure 1 with figure 2 Shown, comprise two water tanks 2 (left and right each one), two gas cylinders 3 (left and right each one) and a driving device; Two water tanks 2 upper end openings store aqueous solution 1 therein; The lower end of the air cylinder 3 is open, and its lower end opening is located below the liquid level of the water cylinder 2; The air intake pipes share the same air inlet 7; the upper end faces of the two air cylinders 3 are connected to an air outlet pipe 8, and the two air outlet pipes 8 are provided with a check valve 6, and the air outlet pipes 8 of the two air cylinders 3 share the same air outlet 9 .

[0030] The driving device comprises a lever 10, a support 11, two pull rods 12 and a driving motor; one end of the lever 10 is connected with the upper end face of one of the gas cylinders, and the other end is connected with the upper end face of the other gas cylinder, and ...

Embodiment 2

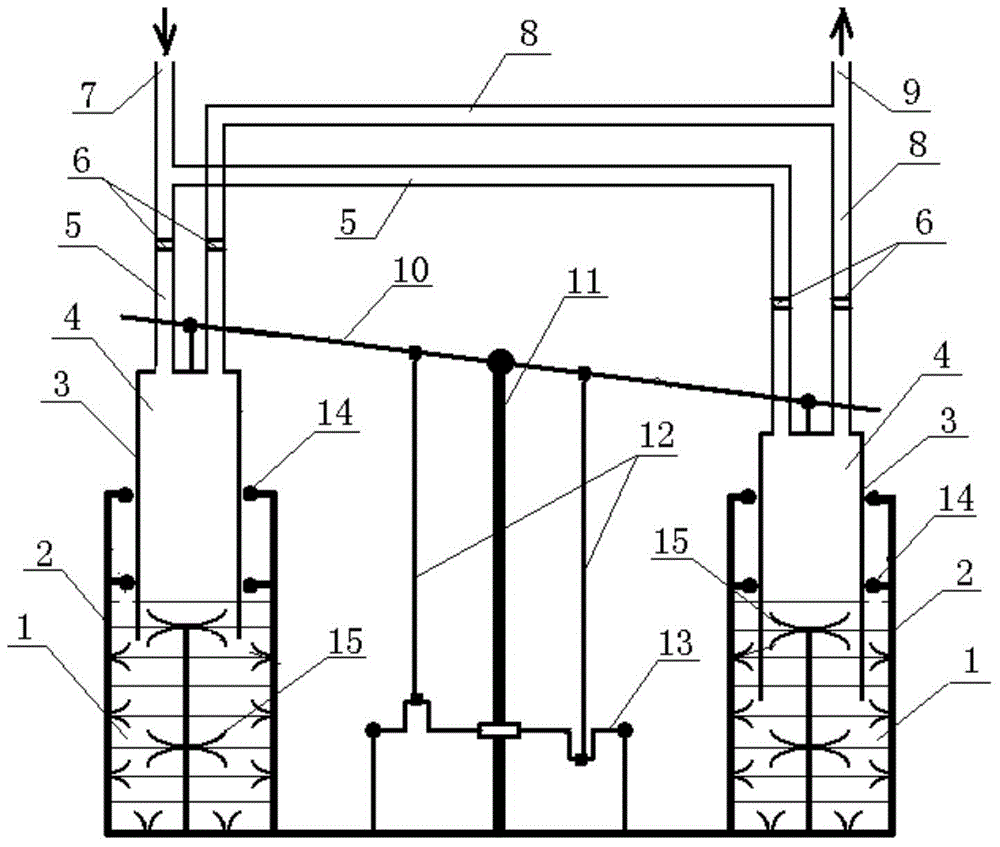

[0033] The difference between this embodiment and Embodiment 1 is: a waterproof shock plate 15 and a guide frame 14 for guiding the air cylinder to move up and down are provided in the water tank, such as image 3 with Figure 4 shown.

[0034] In this embodiment, the setting of the waterproof shock sheet is to reduce the vibration amplitude of the aqueous solution in the water tank when the water piston blower is working, so as to ensure its working stability; the setting of the guide frame is to When the water piston blower is working, it guides the air cylinder so that it can always be perpendicular to the water surface, and further ensures its working stability.

Embodiment 3

[0036] The difference between this embodiment and Embodiment 1 and Embodiment 2 is: the power source is a cylinder, the piston rod of the cylinder is connected with the lever, and is away from the fulcrum, and its end is fixedly installed on the bottom end of the bracket (not shown in the figure), Only one cylinder can realize the working effect described in Embodiment 1 and Embodiment 2, and its structure and principle are very simple.

[0037] The above embodiments are all a kind of double-piston and double-cylinder suction and blowing machine, which can not only realize the intermittent suction and blow function, but also the continuous suction and blow function; The machine can realize the function of the intermittent suction and blower; when the suction and blower is equipped with more than two water cylinders and air cylinders, it not only has the function of a double-piston double-cylinder suction and blower, but also can control multiple devices at the same time. Perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com