A solar cogeneration tube

A technology of combined heat and power generation and solar heat collection, which is applied in solar thermal power generation, solar thermal devices, electrical components, etc., can solve the problems of vacuum tube manufacturing process, waste of ground cost, and impact on power generation, etc., so as to improve energy utilization rate and structure. Simple, easy to mass-produce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

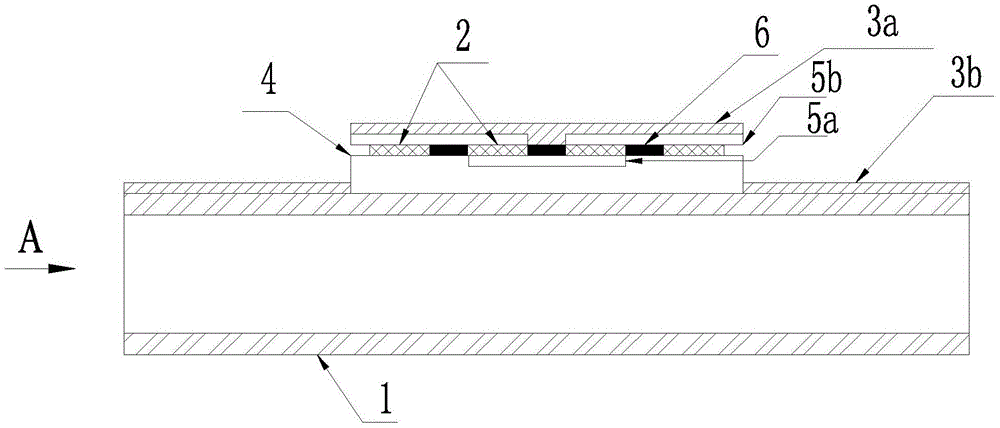

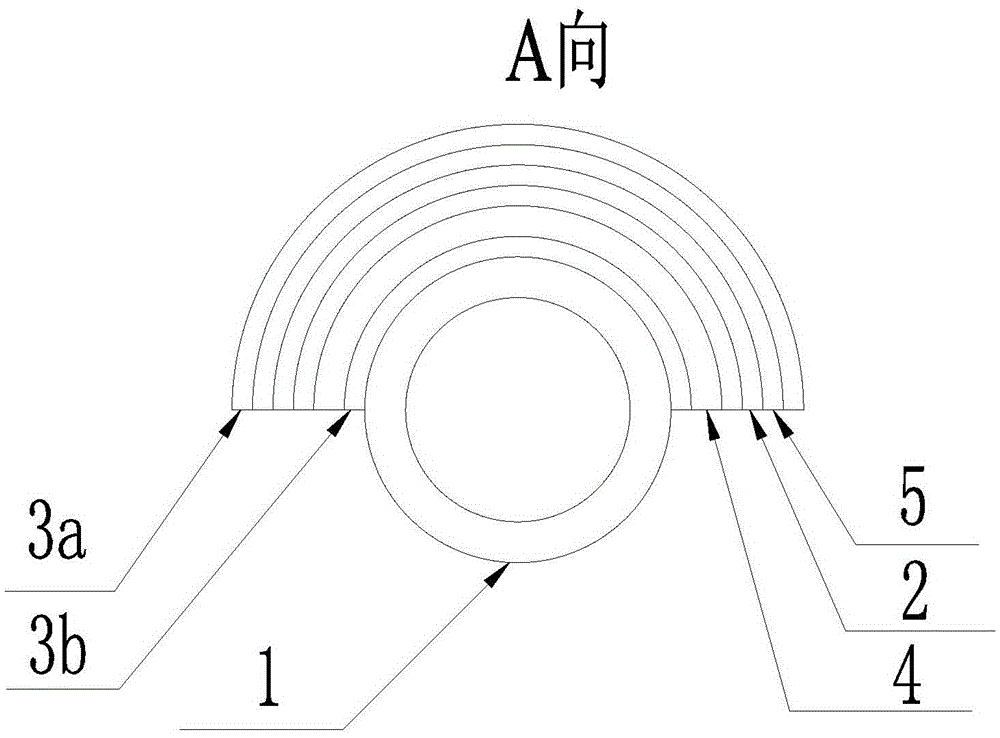

[0031] see figure 1 and figure 2 , a solar cogeneration tube of the present invention, comprising a glass water pipe 1, and an insulating ceramic layer 4 arranged on the outer wall of the glass water pipe 1, a plurality of PN junction thermoelectric power generation components 2 are arranged on the outer wall of the insulating ceramic layer 4, and several PN Two adjacent P-type semiconductors and N-type semiconductors in the junction thermoelectric power generation component 2 are separated by an insulating material layer 6 so that they can be closely attached to the insulating material layer 6 to ensure good contact. The P-type semiconductor and N-type semiconductor of two adjacent PN junction thermoelectric power generation components 2 are connected through the first conductive film 5a embedded on the outer wall of the insulating ceramic 4, which is equivalent to connecting different PN junction thermoelectric power generation components 2 in series. The P-type semiconduc...

Embodiment 2

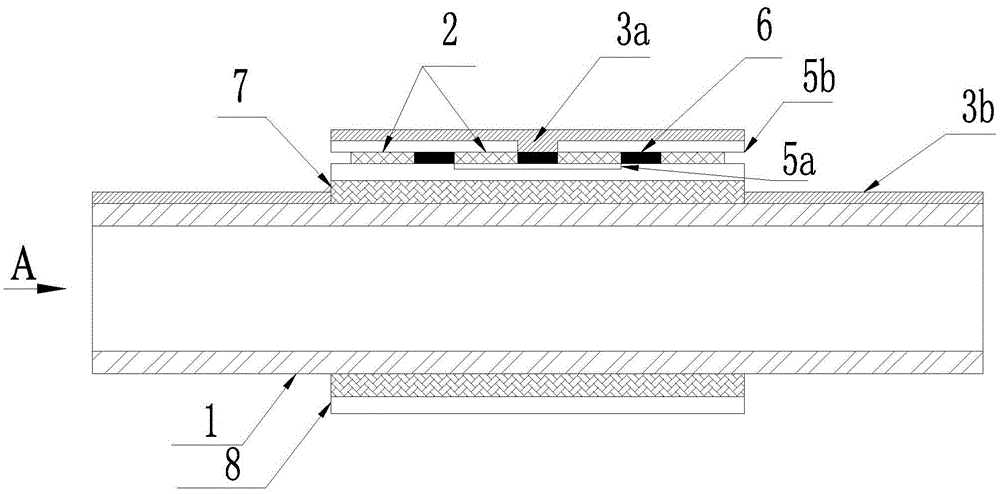

[0035] see image 3 and Figure 4 , a kind of solar heat and power cogeneration tube of the present invention, comprises glass water pipe 1, and the insulating or glass fiber layer 7 that is arranged on the outer wall of glass water pipe 1 and glass casing 8 successively from inside to outside, and the outer wall of glass casing 8 is provided with A plurality of PN junction thermoelectric power generation components 2, and two adjacent P-type semiconductors and N-type semiconductors in the plurality of PN junction thermoelectric power generation components 2 are separated by an insulating material layer 6, and the P of two adjacent PN junction thermoelectric power generation components 2 The P-type semiconductor and the N-type semiconductor are connected through the first conductive film 5a embedded on the outer wall of the insulating ceramic 4, and the P-type semiconductor and the N-type semiconductor of the single PN junction thermoelectric power generation assembly 2 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com