Method for detecting texture performance of thermal simulation experiment material

A technology of tissue properties and experimental materials, applied in the direction of analyzing materials, testing material strength using stable tension/pressure, measuring devices, etc., can solve the problems of decreased strain and temperature uniformity, decreased research accuracy, and limited application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to the following embodiments.

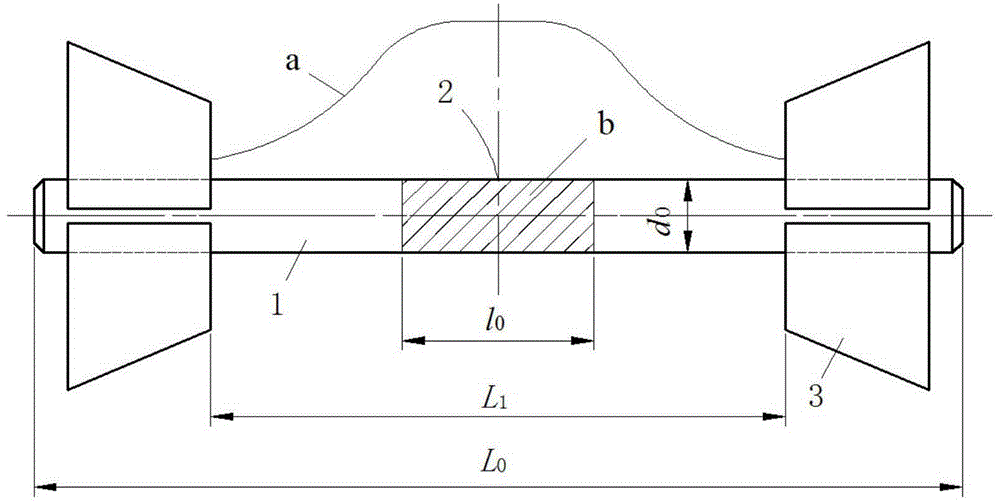

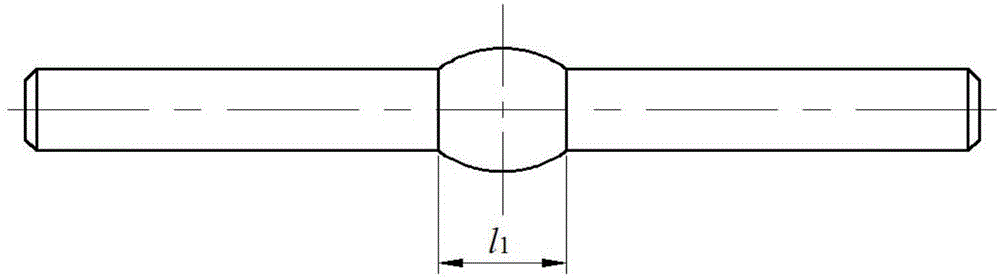

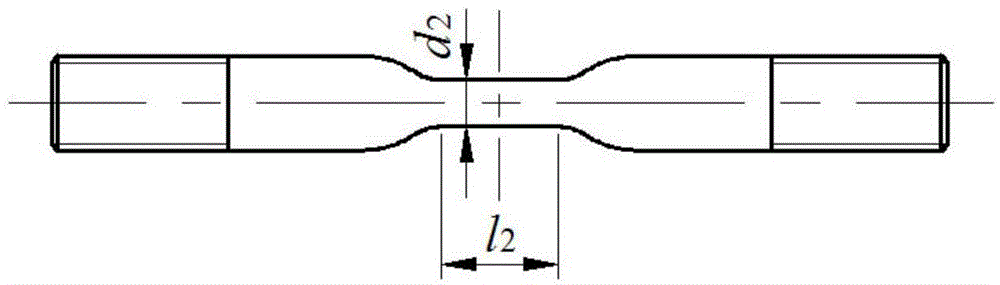

[0023] The present invention sets three process parameters, respectively, process 1: the deformation temperature in the uniform temperature zone is 850°C, and the cooling rate is 4°C / s; process 2: the deformation temperature in the uniform temperature zone is 800°C, and the cooling speed is 8°C / s Cool to 550°C, then slowly cool at 1°C / s; Process 3: The deformation temperature in the uniform temperature zone is 800°C, quickly cool to 550°C at 5°C / s, and then slowly cool at 2°C / s. The effects of controlled rolling and controlled cooling process parameters on the microstructure and properties of steel were studied on the Gleeble3500 thermal simulation testing machine. Make the sample into a cylindrical shape of Ф10mm×86mm, place it in the thermal simulation testing machine, weld the the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com