Eyeglass lens with high color contrast degree and manufacturing method

A spectacle lens and contrast technology, applied in glasses/goggles, optics, instruments, etc., can solve the problems of reducing eye color discrimination, visual color discrimination reduction, affecting visual recognition ability, etc., to achieve easy visual observation and improve contrast Resolution, easy to distinguish effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

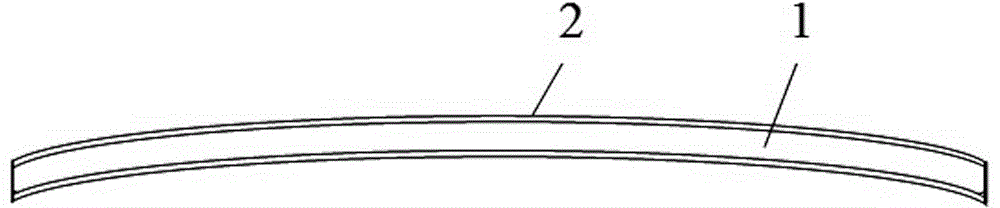

[0045] Such asfigure 1 As shown, the high color contrast spectacle lens includes a substrate 1 and a strengthening film layer 2;

[0046] Substrate 1 is prepared by mixing high molecular polymer, dispersant, solvent and ultraviolet absorber; the high molecular polymer is polyamide (PA), commonly known as nylon, or polycarbonate (PC); the dispersant and solvent are Disperse Violet 26 (CAS №: 6408-72-6), Solvent Blue 97 (CAS №: 32724-62-2), Solvent Violet 36 (CAS №: 61951-89-1) and Solvent Green (CAS №: 128 -80-3) mixture, the content of disperse violet 26 is 40%, the content of solvent blue 97 is 30%, the content of solvent violet 36 is 20%, the content of solvent green is 10%; the ultraviolet absorber is UV- 531;

[0047] The ratio of high molecular polymer to the mixture composed of dispersant solvent is 1000:0.06~0.09; the ratio of high molecular polymer to ultraviolet absorber, polyamide (PA) is 100:3~5; polycarbonate (PC ) is 100:0.3~0.5;

[0048] The strengthening film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com