Tubular solid oxide fuel cell sealing material, tubular solid oxide fuel cell stack, and preparation methods of tubular solid oxide fuel cell sealing material and tubular solid oxide fuel cell stack

A technology of solid oxide and fuel cell stacks, which is applied in the direction of solid electrolyte fuel cells, fuel cells, fuel cell groups, etc., can solve the problems of lagging battery products, no long-term operation of kilowatt or megawatt fuel cell stacks, etc., and achieve production Low cost, easy industrial production and application, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

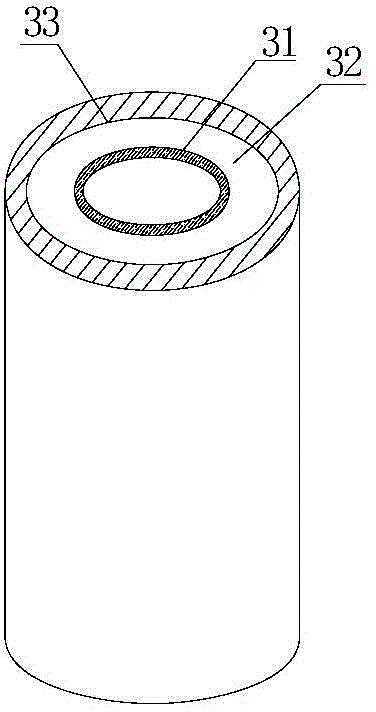

[0031] Such as image 3 As shown, the present embodiment tubular solid oxide fuel cell sealing material 3 includes a conductive layer 31, a sealing layer 32 and a bonding layer 33 from the inside to the outside, the conductive layer 31 is an Ag metal tube, and the surface is coated with Sr 0.7 La 0.3 Ti 0.5 Fe 0.5 o 3 The base sealing layer 32 is coated with La on the surface of the sealing layer 32 0.7 Sr 0.3 CrO 3 Base adhesive layer 33.

[0032] The method for preparing the sealing material 3 of the tubular solid oxide fuel cell in this embodiment includes the following steps:

[0033] Step 1: Using PVA as a dispersant, the ball ink grinding method is used to prepare Sr with a solid content of 15wt%. 0.7 La 0.3 Ti 0.5 Fe 0.5 o 3 Base slurry;

[0034] Step 2: Using PVA as a dispersant, the ball ink grinding method makes La with a solid content of 15wt%. 0.7 Sr 0.3 CrO 3 slurry;

[0035] Step 3: The conductive layer 31 is supported by an Ag metal tube, and th...

Embodiment 2

[0044] In this embodiment, the conductive layer 31 of the sealing material 3 of the tube-type solid oxide fuel cell is supported by an Ag metal tube, and the surface is coated with Sr. 0.7 La 0.3 Ti 0.5 Ni 0.5 o 3 Base sealing layer 32, other contents are the same as Example 1.

Embodiment 3

[0046] Such as image 3 As shown, the present embodiment tubular solid oxide fuel cell sealing material 3 includes a conductive layer 31, a sealing layer 32 and an adhesive layer 33 from the inside to the outside. The conductive layer 31 is a Cu metal tube, and the surface is coated with Sr 0.7 Y 0.3 Ti 0.5 Fe 0.5 o 3 The base sealing layer 32 is coated with a LaCrO3-based bonding layer 33 on the surface of the sealing layer 32 .

[0047] The method for preparing the sealing material 3 of the tubular solid oxide fuel cell in this embodiment includes the following steps:

[0048] Step 1: Using PVA as a dispersant, the ball ink grinding method is used to prepare Sr with a solid content of 15wt%. 0.7 Y 0.3 Ti 0.5 Fe 0.5 o 3 Base slurry;

[0049] Step 2: Using PVA as a dispersant, the ball ink grinding method is used to prepare LaCrO with a solid content of 15wt%. 3 slurry;

[0050] Step 3: The conductive layer 31 is supported by a Cu metal tube, and the surface is uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com