Planar EMI filter integrating common mode inductors, differential mode inductors and differential mode capacitors

A technology of common-mode capacitors and differential-mode inductors, which is applied in the field of filters, can solve the problems of large size, large filter flux leakage, and poor filtering effect, and achieve the effects of improving utilization, reducing volume, and suppressing common-mode noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

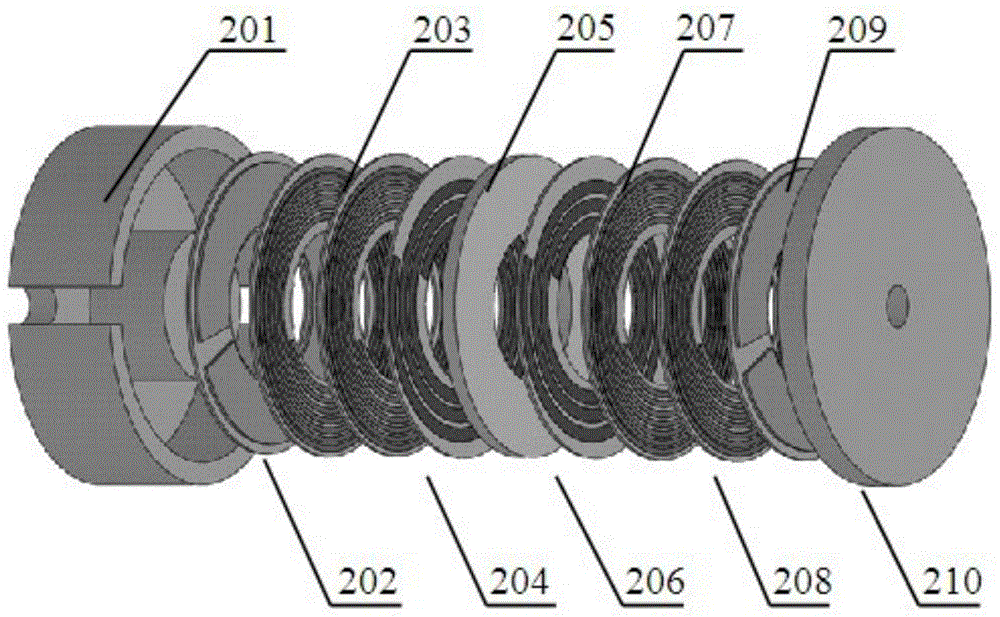

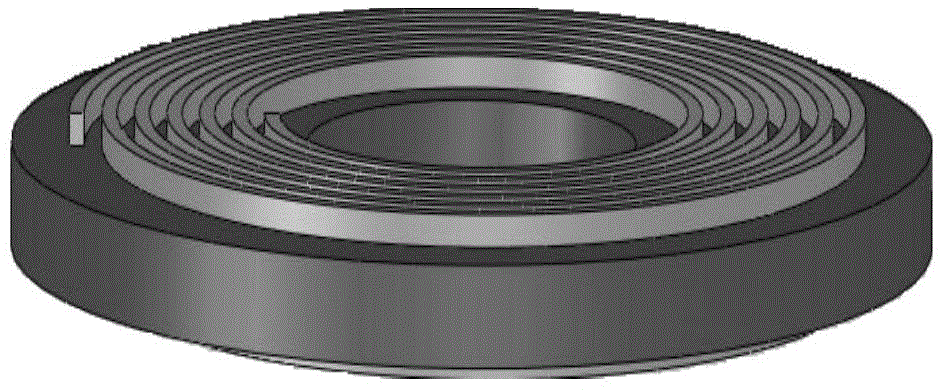

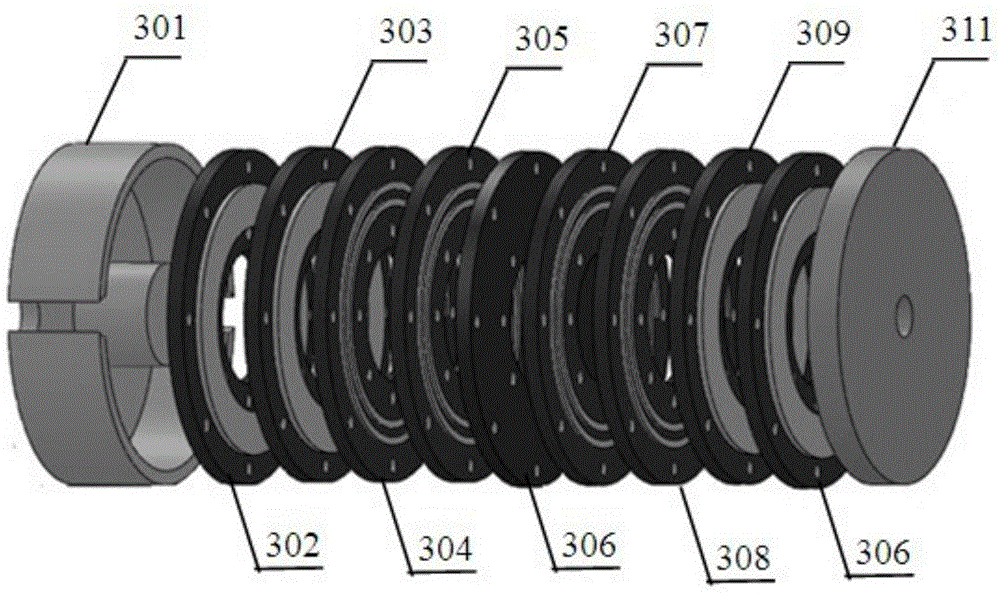

[0030] Such as Figure 2A In the example shown, a planar EMI filter integrating common-mode inductors, differential-mode inductors, and differential-mode capacitors includes a pot-type magnetic core 301, a planar magnetic core 311, a common-mode capacitor, an integrated inductive capacitor structure, and a leakage inductance layer 306, wherein The common-mode capacitor and the integrated inductance structure form the inductance unit. The two inductance units are separated by the leakage inductance layer and are symmetrically arranged on both sides of the leakage inductance layer. The inductance unit on the left side of the leakage inductance layer is the first inductance unit. unit, the inductance unit on the right side of the leakage inductance layer is the second inductance unit, and the integrated inductance structure on both sides of the leakage ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com