Olefin hydroformylation catalyst

A technology of olefin hydroformylation catalyst and rhodium catalyst, which is applied in the direction of physical/chemical process catalyst, organic compound/hydride/coordination complex catalyst, organic chemistry, etc., and can solve the problem of low reaction activity, poor stability, positive and negative to achieve high catalytic activity, prolong service life, reduce separation energy consumption and achieve the effects of low specific ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

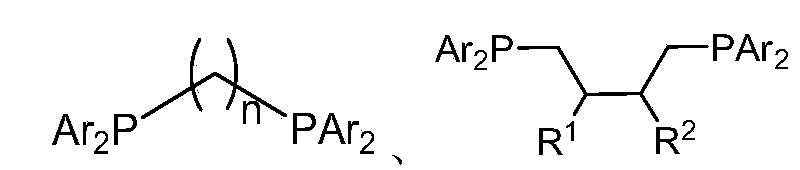

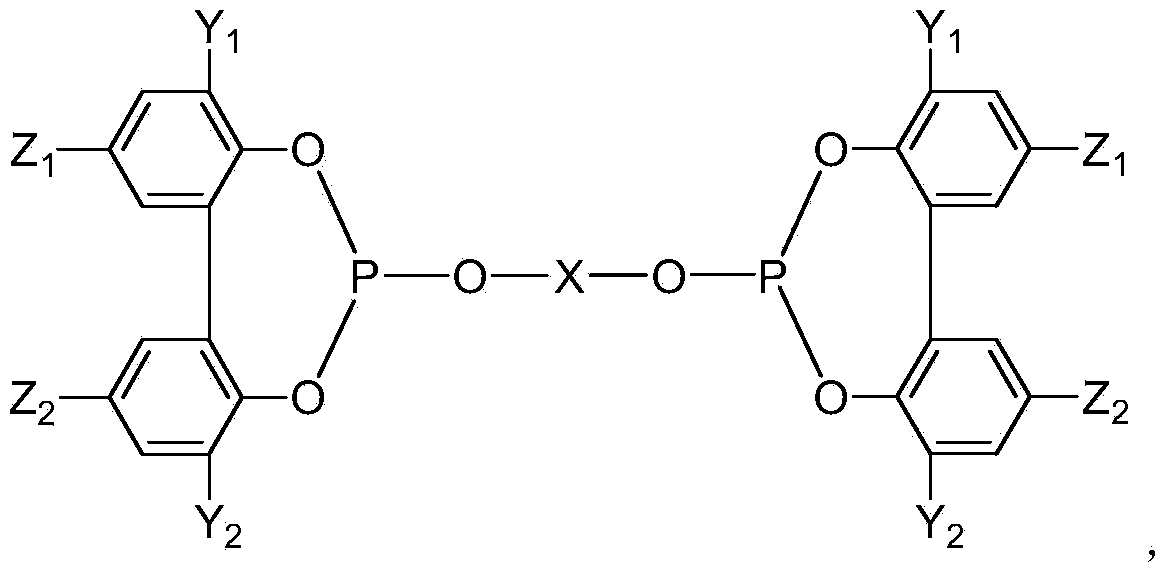

Method used

Image

Examples

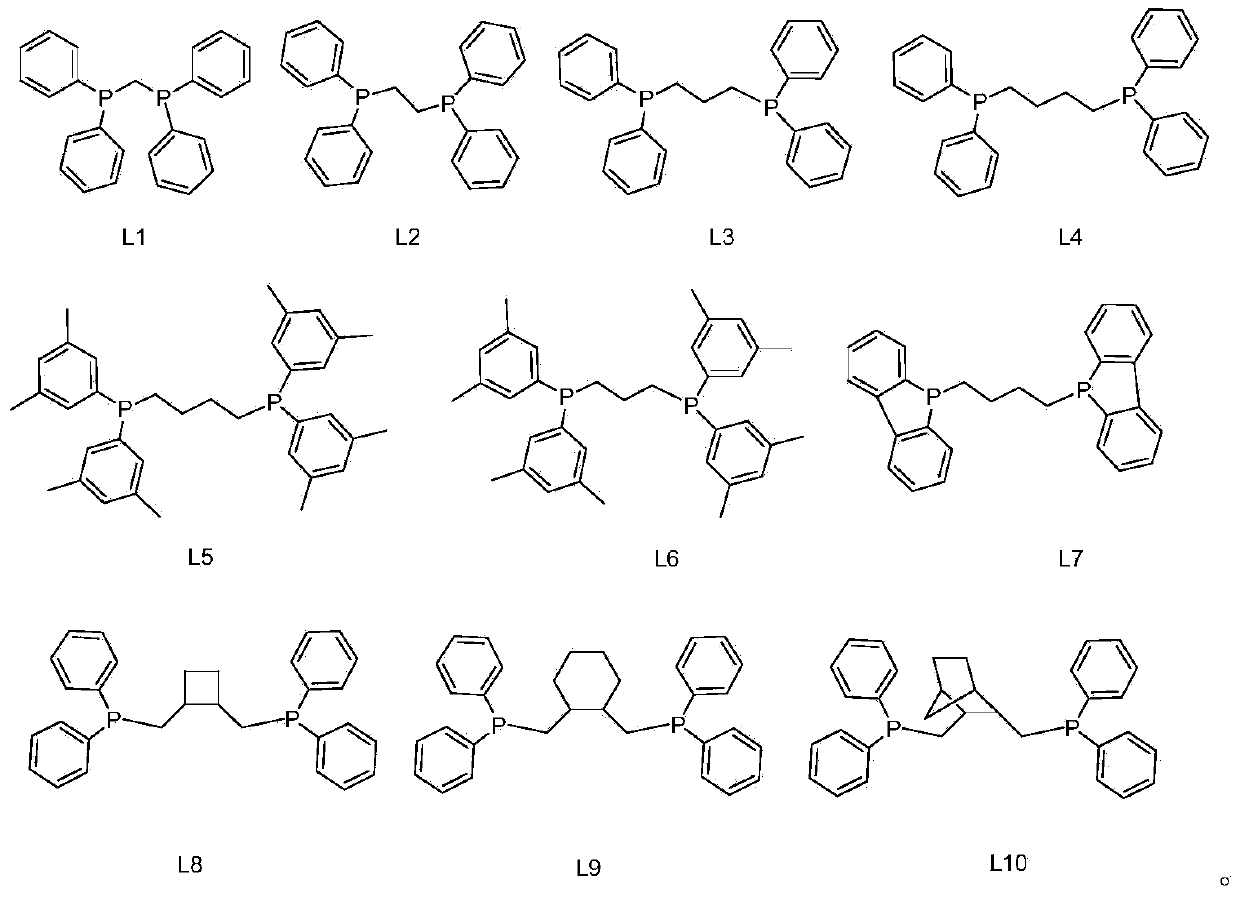

Embodiment 1

[0048] Add rhodium(I)[Rh(acac)(CO) dicarbonyl acetylacetone to a 200mL stainless steel autoclave equipped with a pressure gauge under air atmosphere 2 ] (0.01mmol, 2.5mg, the concentration is 103mg / L) and 0.04mmol of 1,4-bis(diphenylphosphine)butane L4 bidentate phosphine ligand and 0.04mmol of L15 bidentate phosphite ligand, And 70mL of anhydrous toluene, connect the gas pipeline, replace the gas in the kettle with nitrogen three times, introduce 15g of propylene, heat up to the temperature of the reaction kettle to 100 ° C, stir with an electromagnetically driven mechanical stirrer, and feed hydrogen and carbon monoxide (volume Ratio 1:1) mixed gas to a total pressure of 2MPa, and maintain the reaction pressure at 2MPa, measure the carbon monoxide and hydrogen consumed by the reaction with a mass flow meter, and stop feeding the mixed gas of hydrogen and carbon monoxide after 1 hour of reaction. Reaction kettle is cooled with ice water, vents residual gas in fume hood, weigh...

Embodiment 2

[0050] Add [Rh(acac)(CO) to a 200mL stainless steel autoclave equipped with a pressure gauge under air atmosphere 2 ] (0.01mmol, 2.5mg, 103mg / L) and 0.04mmol of the L5 bidentate phosphine ligand and 0.04mmol of the L13 bidentate phosphite ligand, and 70mL of anhydrous toluene, connect the gas line, and replace the kettle with nitrogen After gas three times, introduce 15g of propylene, heat up to the inner temperature of the reactor to 100°C, stir with an electromagnetically driven mechanical stirrer, and introduce a mixture of hydrogen and carbon monoxide (volume ratio 1:1) to a total pressure of 2MPa, and maintain The reaction pressure is at 2 MPa, and the carbon monoxide and hydrogen consumed by the reaction are measured with a mass flow meter. After 1 hour of reaction, the mixed gas of hydrogen and carbon monoxide is stopped. Reactor is cooled with ice water, vents residual gas in fume hood, weighs, open still, and sampling is measured positive isotropic ratio (the mol rati...

Embodiment 3

[0052] Add [Rh(acac)(CO) to a 200mL stainless steel autoclave equipped with a pressure gauge under air atmosphere 2 ] (0.01mmol, 2.5mg, 103mg / L) and 0.04mmol of the L3 bidentate phosphine ligand and 0.04mmol of the L15 bidentate phosphite ligand, and 70mL of anhydrous toluene, connect the gas line, and replace the kettle with nitrogen After gas three times, introduce 15g of propylene, heat up to the inner temperature of the reactor to 100°C, stir with an electromagnetically driven mechanical stirrer, and introduce a mixture of hydrogen and carbon monoxide (volume ratio 1:1) to a total pressure of 2MPa, and maintain The reaction pressure is at 2 MPa, and the carbon monoxide and hydrogen consumed by the reaction are measured with a mass flow meter. After 1 hour of reaction, the mixed gas of hydrogen and carbon monoxide is stopped. Reactor is cooled with ice water, vents residual gas in fume hood, weighs, open still, and gas chromatography (GC) is used for sampling to measure pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com