Simple waste tyre port ring separator

A waste tire and separator technology, which is applied in recycling technology, metal processing, plastic recycling, etc., can solve the problems of complex structure, complex use process, power consumption, etc., and achieve the effect of simple structure, convenient operation and high efficiency of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

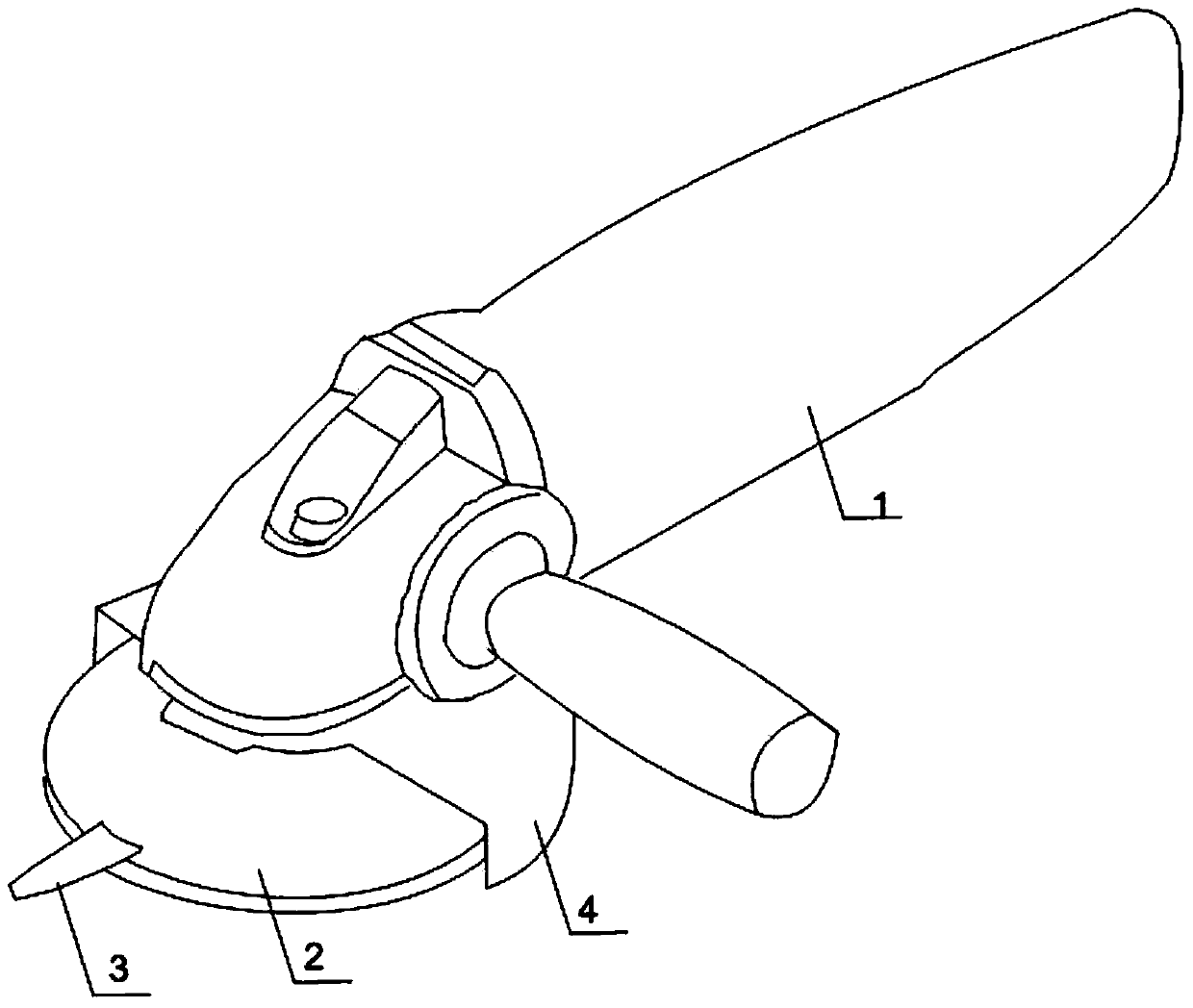

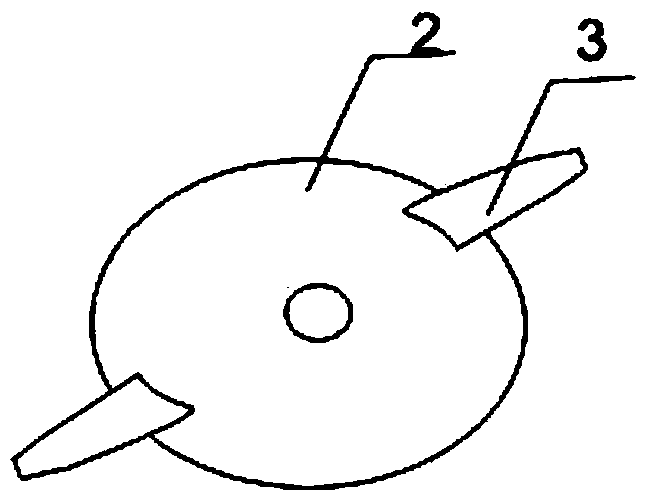

[0014] Such as Figure 1-2 As shown, the simple waste tire rim separator of the present invention is composed of an angle grinder body 1, a rotating disc 2, an alloy cutter head 3, a shield 4 and other components.

[0015] The angle grinder body 1 is an existing portable angle grinder, and the angle grinder body 1 is provided with a shield 4. The structure of the angle grinder is in the prior art, and will not be repeated here.

[0016] The rotating disk 2 is a metal disk, preferably a waste and cutting piece, with low cost and environmental protection. In the center of the rotating disk 2, there is a central hole for installing the rotating disk 2 on the output shaft of the angle grinder body 1. The output shaft of the angle grinder body 1 itself is equipped with a grinding wheel. We will take the grinding wheel out Next, the rotating disk 2 is mounted on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com