A high-efficiency extraction separator for volatile oil

A separator, volatile oil technology, applied in the direction of essential oils/spice, fat generation, etc., to reduce liquid temperature, eliminate collision and disturbance, and increase distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific embodiments.

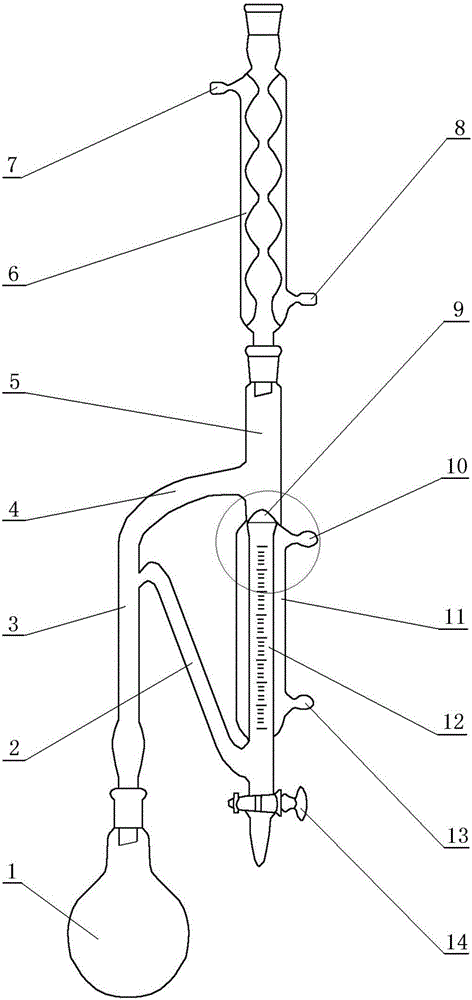

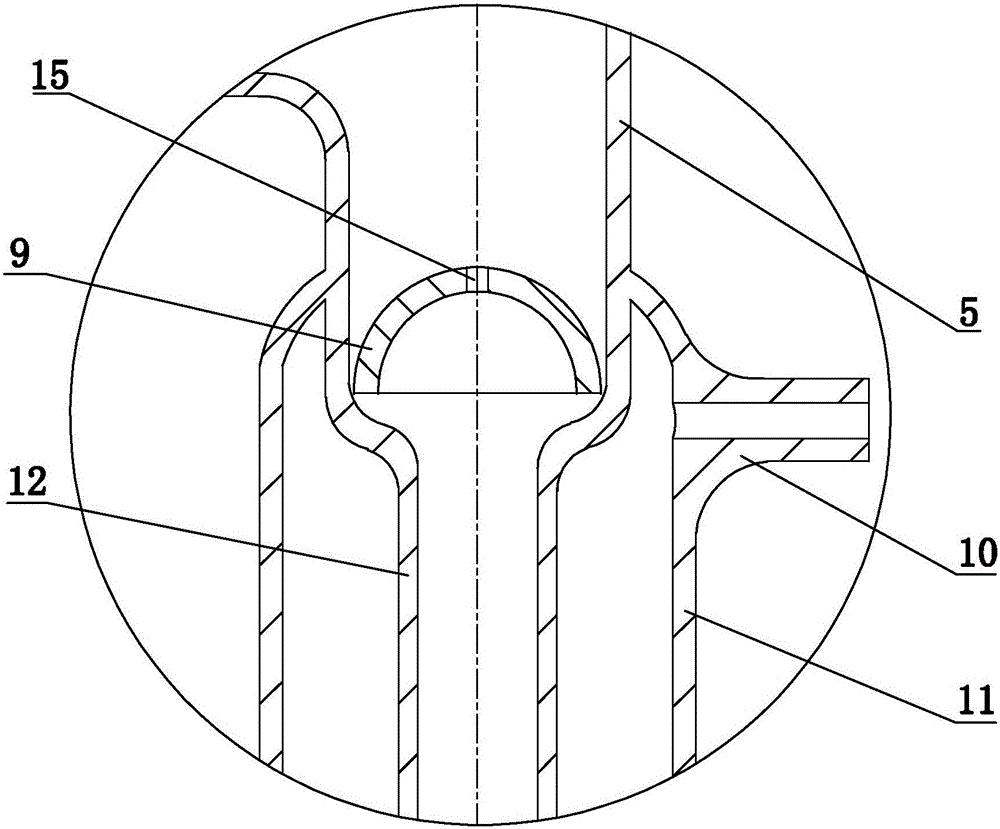

[0015] The present invention is the improvement carried out to existing conventional volatile oil extractor, as figure 1 , figure 2 As shown, this improved volatile oil high-efficiency extraction separator includes a steam outlet pipe 3 connected to the round bottom flask 1. The steam outlet pipe 3 passes through the communication pipe 4 and then passes through the side and the liquid storage pipe 5 and the inclined return pipe. 2. The upper nozzles are connected, and the liquid storage pipe 5 is connected with a condenser 6. The condensate outlet of the condenser 6 is connected with the separation pipe 12 through the liquid storage pipe 5 and the top inlet of the separation pipe 12. The inner diameter of the separation pipe 12 is less than The inner diameter of the liquid storage pipe 5, the lower outlet of the separation pipe 12 is connected to the lower nozzle of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com