Steel tube bundle combination structure with flanged U-shaped section bars

A combined structure and steel pipe bundle technology, which is applied to building components, building structures, walls, etc., can solve problems such as difficult construction, complicated component production, and a large amount of labor, and achieve reliable product quality, save labor, and facilitate welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

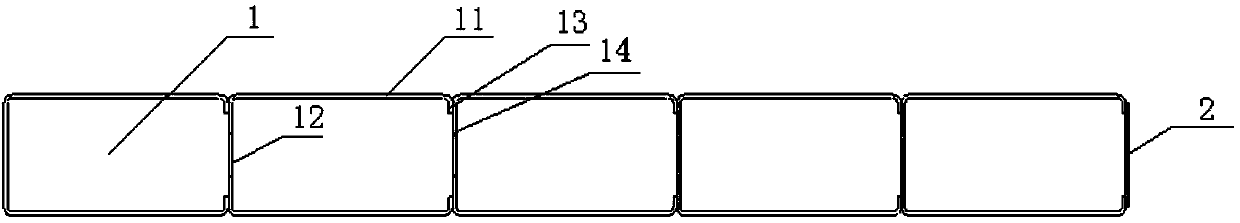

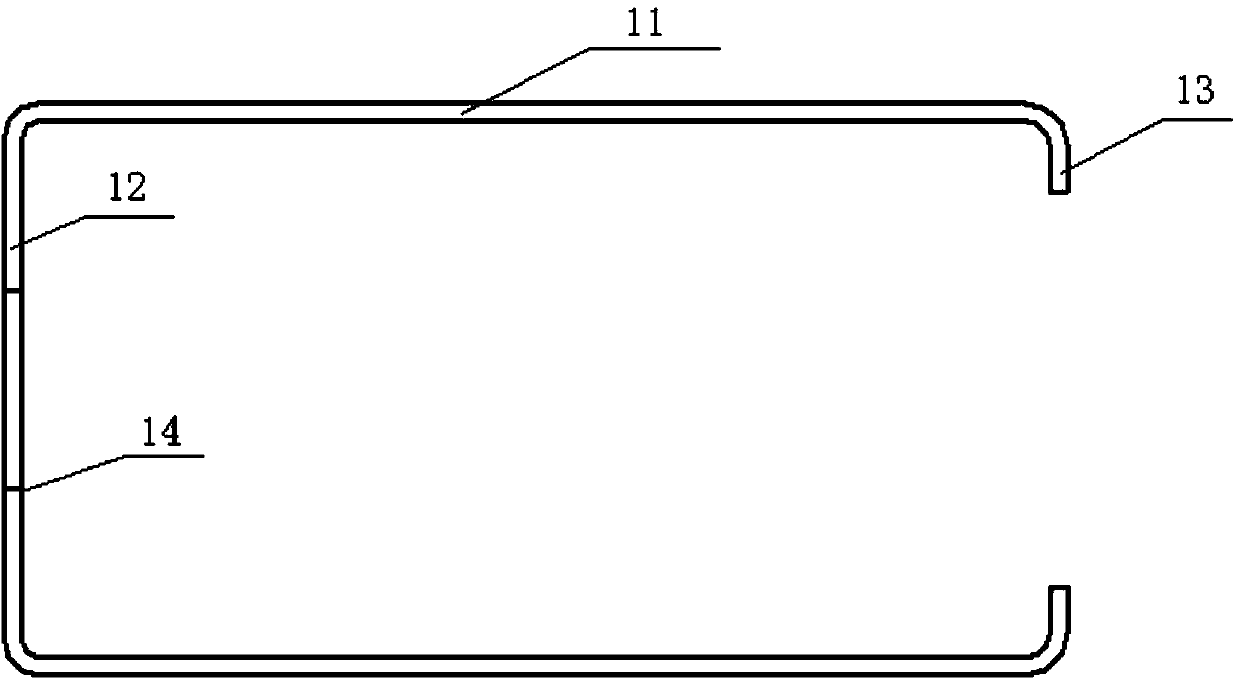

[0025] refer to Figure 1 to Figure 2 , a combined structure of steel pipe bundles of U-shaped profiles with folded edges, which is composed of a steel pipe bundle assembly, the steel pipe bundle assembly is composed of a plurality of steel pipe units 1 connected in sequence, and the steel pipe units 1 have cavities, Pouring concrete in the cavity;

[0026] The steel pipe unit 1 is a U-shaped profile in cross section, the U-shaped profile of the steel pipe unit includes a bent bottom 12, two side walls 11, and an opening is formed between the ends of the two side walls 11. Splicing the bending bottom 12 of the U-shaped profile of the adjacent steel pipe unit at the opening described above;

[0027] The end of the side wall of the U-shaped profile has a bending section 13 parallel to the bending bottom and opposite to the bending direction, and the bending section 13 is connected to the bending bottom. 12 welding; the bent bottom 12 constitutes a partition between adjacent st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com