High-manganese steel inset high-chromium cast iron jaw plate and manufacturing method thereof

A technology of high-chromium cast iron and high-manganese steel, applied in grain processing and other directions, can solve the problems of high operation requirements and difficult to achieve close coordination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

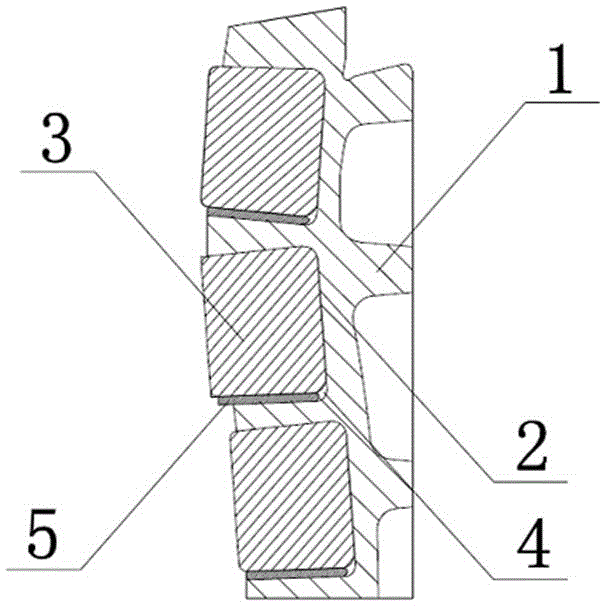

[0022] Embodiment 1: as figure 1 As shown, a high-manganese steel inlaid high-chromium cast iron jaw plate includes a high-manganese steel casting base 1, and the high-manganese steel casting base 1 is provided with several tooth peaks arranged in parallel at intervals and interspersed between two adjacent tooth peaks. Tooth valley, each tooth crest is provided with a number of dovetail grooves 4 that are small in size and large in size, that is, a trapezoidal cavity, and each dovetail groove 4 is equipped with a trapezoidal high-chromium cast iron mosaic block whose volume is smaller than the cavity 3. Of the four sets of mating surfaces facing each other among the four trapezoidal side surfaces of the trapezoidal body of the high chromium cast iron mosaic block 3 and the trapezoidal cavity walls of the dovetail groove 4, at least one of the mating surfaces but at most three of them are matched The surfaces are veneer abutment, and there are at most three sets of mating surfa...

Embodiment 2

[0023] Embodiment 2: The rest is the same as Embodiment 1, the high chromium cast iron mosaic block 3 protrudes outside the dovetail groove 2 of the high manganese steel casting substrate 1 .

[0024] A method for manufacturing a high manganese steel inlaid high chromium cast iron jaw plate, comprising the following steps:

[0025] (1) One piece of prefabricated high manganese steel casting base, on which there are several tooth peaks arranged in parallel at intervals and tooth valleys interspersed between two adjacent tooth peaks, and each tooth peak is provided with several outer small The large inside is the dovetail groove with trapezoidal cavity;

[0026] (2) A number of prefabricated high-chromium cast iron mosaic blocks, the number of which is equal to the number of dovetail grooves on the base of the whole high-manganese steel casting. , but the height of each high chromium cast iron mosaic block is higher than the cavity of the dovetail groove, that is, the high chro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com