Novel expansion tank

An expansion tank, a new type of technology, applied in the direction of engine components, machines/engines, engine cooling, etc., can solve the problems of complex drainage, affecting the cooling of diesel engine intake oil, etc., to facilitate piping, reduce high and low temperature water Reduces the effect of the upper drain operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

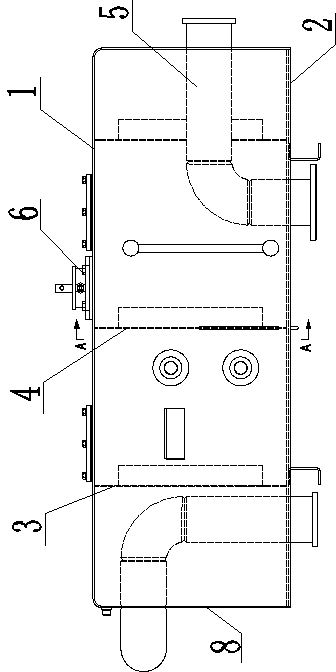

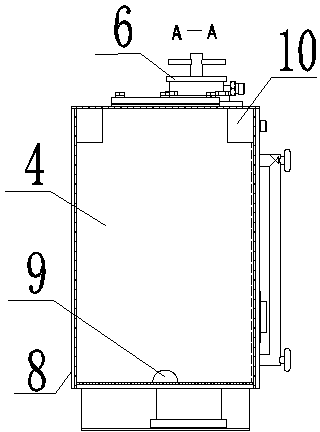

[0013] Such as figure 1 It is a structural schematic diagram of the present invention, figure 2 It is the A-A cross-sectional view of the present invention, a new type of expansion tank, including U-shaped plate 1, flat plate 2, wave-proof plate 3, partition 4, embedded water pipe 5 and pressure valve 6, U-shaped plate 1 and flat plate 2 are welded into a box The body 8, the anti-wave plate 3, the partition plate 4 and the embedded water pipe 5 are installed inside the box body 8, and the pressure valve 6 is connected to the top of the box body 8. The U-shaped plate 1 is covered on the top of the plate 2 assembly. The anti-wave plate 3 and the partition plate 4 are vertically connected in the box body 8 . The lower part of the partition 4 is provided with a balance hole 9 , and the upper part is provided with a vent 10 .

[0014] The box body 8 is composed of a U-shaped plate 1 and three flat plates 2 welded into a frame, and then the sealing plates on both sides are welde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com