Sliding-vane-type oil delivery pump with springs

An oil pump and sliding vane technology, which is applied in the field of parts and components, can solve the problems of extremely high processing precision of parts, the inability to use high-pressure common rail systems, and poor low-speed adaptability, so as to achieve low processing precision requirements and avoid internal leakage. , to meet the effect of pump oil volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

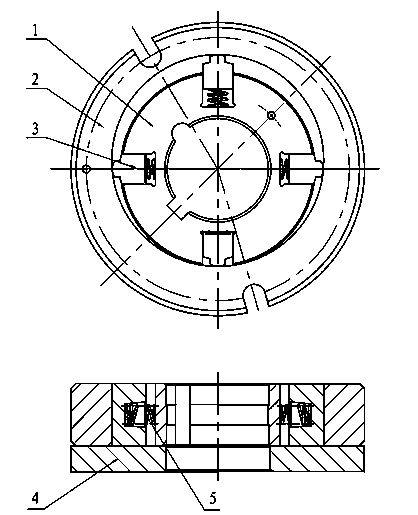

[0016] Such as figure 1 As shown, the rotor 1 is installed on the drive shaft of the high-pressure oil pump. There are 4 sliding slots equidistant around the rotor 1. The sliding piece 3 is installed in the sliding slot and can slide freely along the sliding slot. The sliding piece 3 is tightly attached to the eccentric ring. 2, the vane spring 5 is installed between the bottom of the chute and the vane 3, the eccentric ring 2 is set on the outer edge of the assembled rotor 1, vane 3 and vane spring 5, and the eccentric ring 2 is for The eccentricity of the axis of the drive shaft is 1mm.

Embodiment approach 2

[0018] Use 6 slides. Set 6 sliding slots equidistantly around the rotor 1, and 6 sliding vanes 3 and sliding vane springs 5 are installed in the sliding slots; the eccentricity of the eccentric ring 2 is 2mm; the installation and technical conditions of other parts are the same as those of the implementation plan 1 .

Embodiment approach 3

[0020] Use 8 slides. Set up 8 slide slots equidistantly around the rotor 1, and install 8 slide plates 3 and slide plate springs 5 in the slide slots; the eccentricity of the eccentric ring 2 is 3 mm; the installation and technical conditions of other components are the same as those of Embodiment 1 .

[0021] The operating mechanism of the present invention is: when the rotor 1 is driven to rotate by the drive shaft of the high-pressure oil pump, the sliding plate 3 is thrown out by the centrifugal force, and tightly fits on the inner cavity wall of the eccentric ring 2 . However, due to the eccentric installation of the rotor 1 in the inner cavity of the eccentric ring 2, the sliding vane 3 slides along the groove on the rotor 1, and the volume of the cavity between the two sliding vanes 3 changes from large to small, sucking in the low-pressure inlet. The diesel oil is compressed to the high-pressure outlet, so that the diesel pressure increases rapidly to meet the oil i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Eccentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com