Heating equipment for electrical heating card thermoluminescence dose measurement

A thermoluminescence dose and heating device technology, which is applied in measurement devices, optical radiation measurement, photometry, etc., can solve the problems of inability to linearize multiple detectors, program heating, etc., and achieve the effect of close contact and increased contact degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

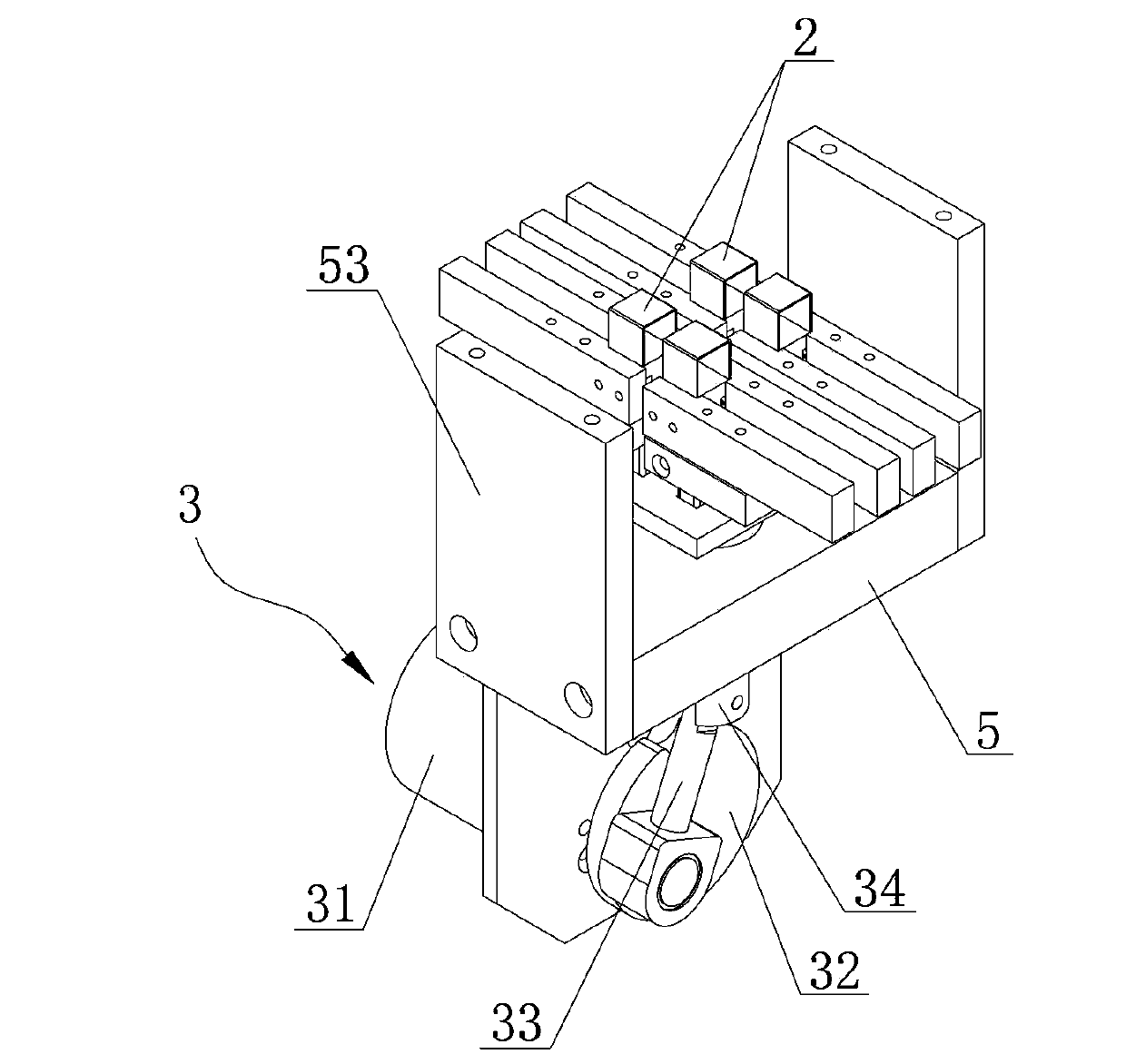

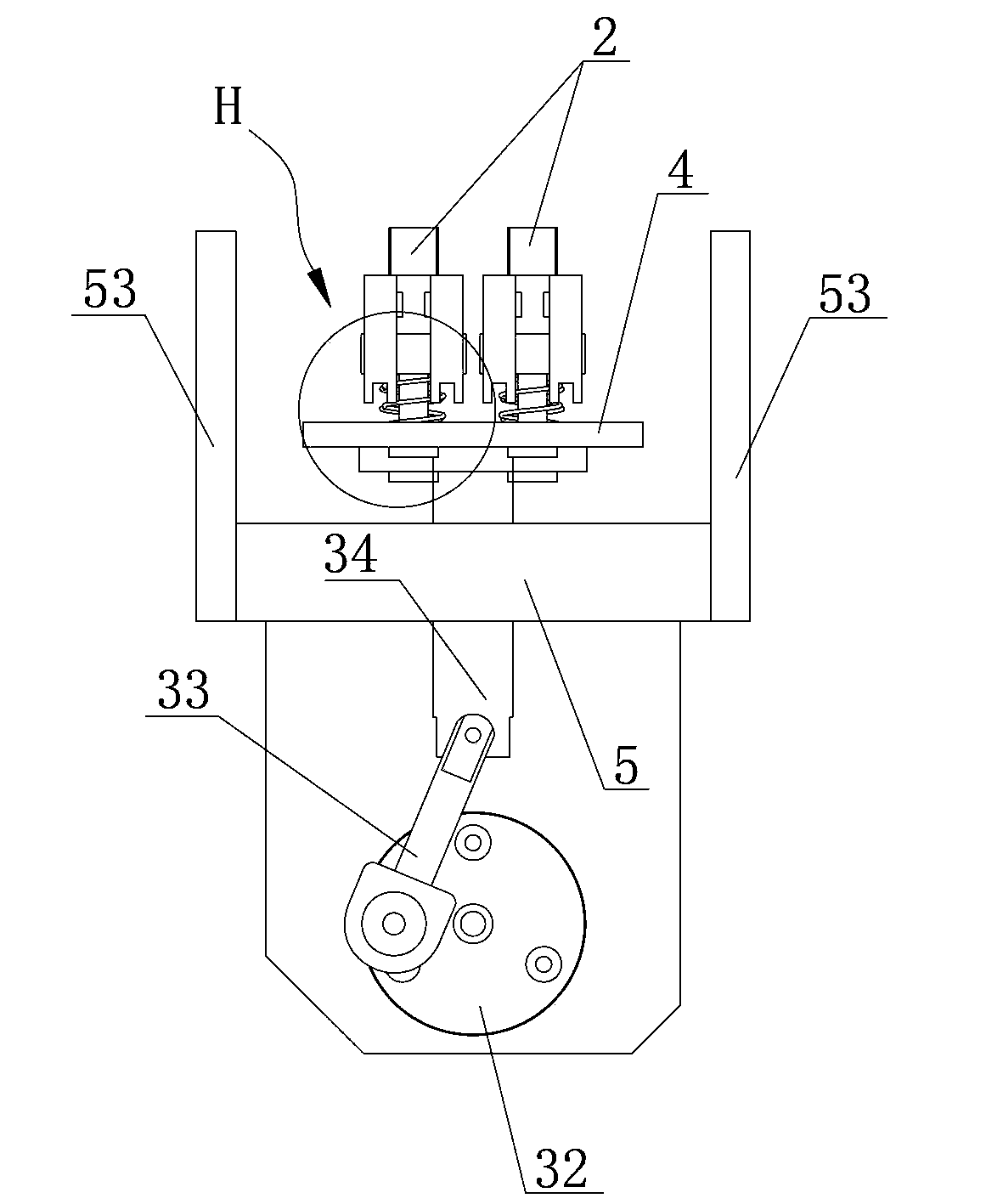

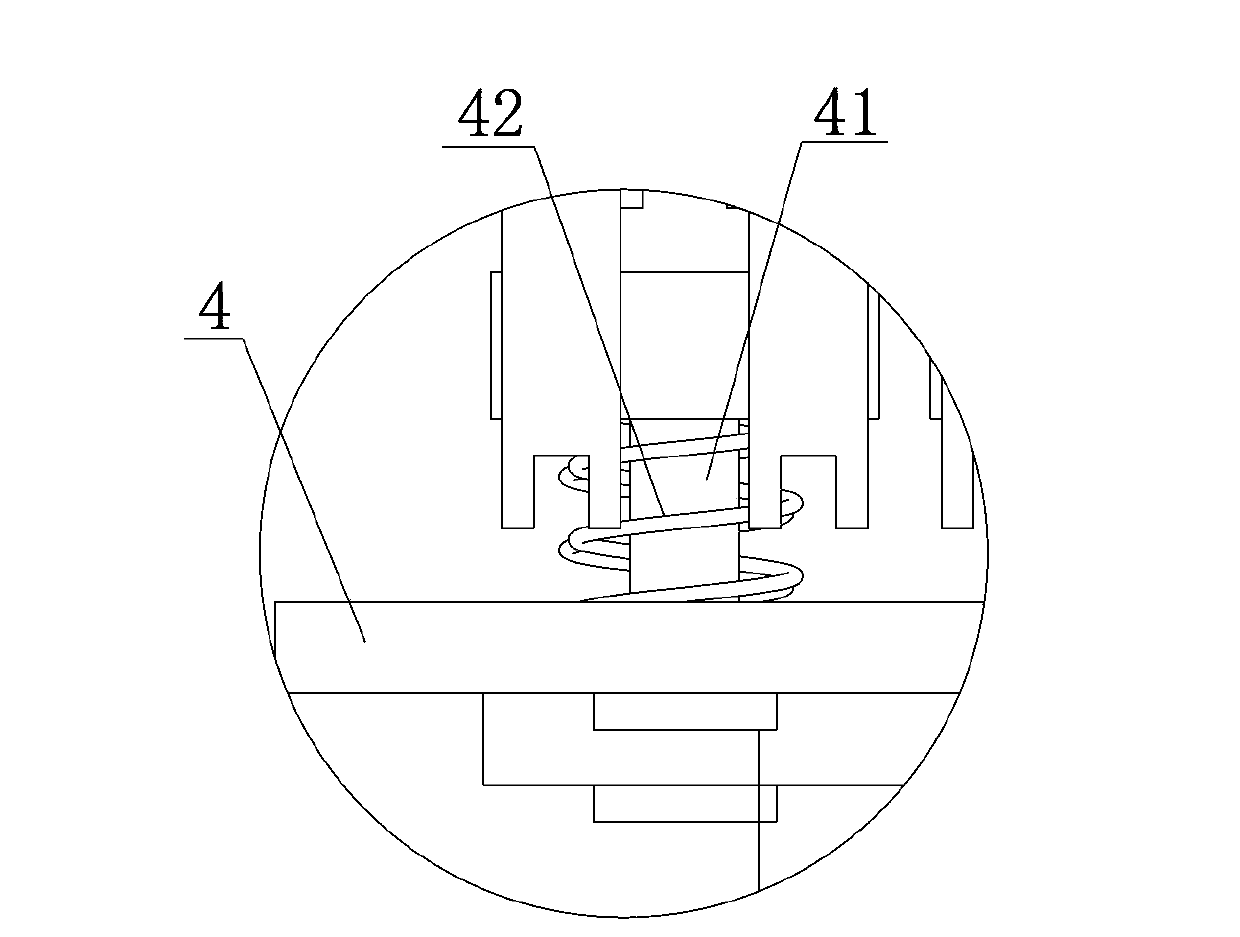

[0026] Such as figure 1 , figure 2 with Figure 4 Commonly shown is an embodiment of the heating device for thermoluminescent dose measurement of the electric heating card of the present invention, including an electric heating mechanism and a power mechanism. Such as Figure 5 with Image 6 Commonly shown is a schematic structural view of the workbench of this embodiment.

[0027] The workbench in this embodiment is a detector tray 1, and a plurality of (four shown in the figure) detector grooves 11 for accommodating detectors are opened on the detector tray 1, as Figure 7 shown, for Figure 5 In the partially enlarged schematic diagram of the position I, the detector tray 1 is also provided with a metal sheet 12 located on the back of the detector groove 11 (ie, the detector). The detector tray 1 is set horizontally when in use, the detector groove 11 is on the top, and the metal sheet 12 is on the bottom. At the same time, a limiter is provided above the detector tr...

Embodiment 2

[0039] The power source of the heating device for measuring the thermoluminescent dose of the electric heating card can also be a vertical cylinder, and the heating head 2 can be directly fixed on the top of the piston of the cylinder, or can be fixed on the top of the cylinder by driving rod 34 and copper plate 4. The piston top of the cylinder.

[0040] The difference between this embodiment and the first embodiment is only that the driving mode is different, and the crank-link mechanism in the first embodiment is replaced by a cylinder, which can also realize the heating function. The rest of the structure in this embodiment is the same as that in Embodiment 1, and will not be repeated here.

[0041] In short, the heating device uses a single-column four-head electric heating device to heat four detectors at one time, which can realize automatic sample replacement and automatic measurement. Moreover, the thermal contact between the heating head and the workbench is good, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com