Frequency converter testing device

A test device and frequency converter technology, applied in the field of frequency converter testing, can solve problems such as waste of human resources, high damage coefficient of electrical equipment, waste of resources, etc., to ensure safety and reliability, improve test efficiency, and reduce experiment risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

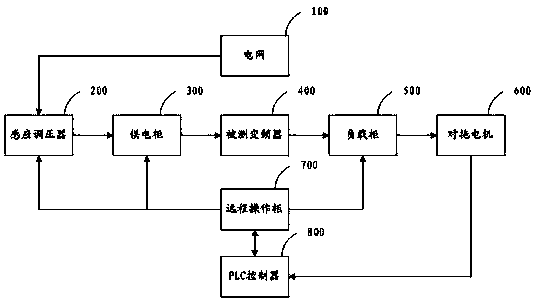

[0038] Such as figure 1 As shown, the frequency converter testing device in this embodiment includes a frequency converter testing device, including:

[0039] The power grid 100 is used to provide test energy to the frequency converter test device;

[0040] An induction voltage regulator 200, used to realize the regulation of the output voltage of the power grid 100;

[0041] The power supply cabinet 300 is used to switch the circuit matching the voltage adjusted by the induction voltage regulator 200;

[0042] To the traction motor 600, used to obtain the load moment;

[0043] The load cabinet 500 is used to load the towed motor 600;

[0044] The remote operation cabinet 700 is used to control the power-on and power-off of the inverter test device, and realize the adjustment of the test voltage, the selection of the power supply test line and the test load through the isolated control of the induction voltage regulator 200, the power supply cabinet 300 and the load cabinet...

Embodiment 2

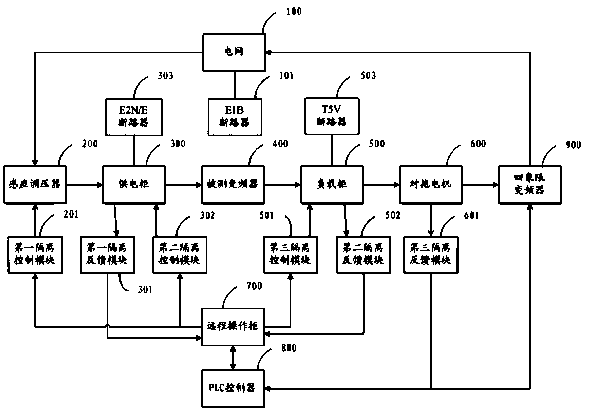

[0056] Such as figure 2As shown, the difference between the frequency converter testing device disclosed in this embodiment and Embodiment 1 is that the frequency converter testing device disclosed in this embodiment also includes the following features:

[0057] In this embodiment, a first isolation control module 201 is also provided between the induction voltage regulator 200 and the remote operation cabinet 700; a first isolation feedback module 301 and a second Two isolation control modules 302; a third isolation control module 501 and a second isolation feedback module 502 are arranged between the load cabinet 500 and the remote operation cabinet 700; Isolated feedback module 601 .

[0058] Among them, the first isolation control module 201, the second isolation control module 302, and the third isolation control module 501 isolate the remote operation cabinet 700 from the power supply cabinet 300, the remote operation cabinet 700 and the load cabinet through the struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com