Dust recycling system and dust recycling treatment method

A technology of dust recovery and dust absorption, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, and can solve problems such as low degree of automation, poor reliability, and small filtration area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

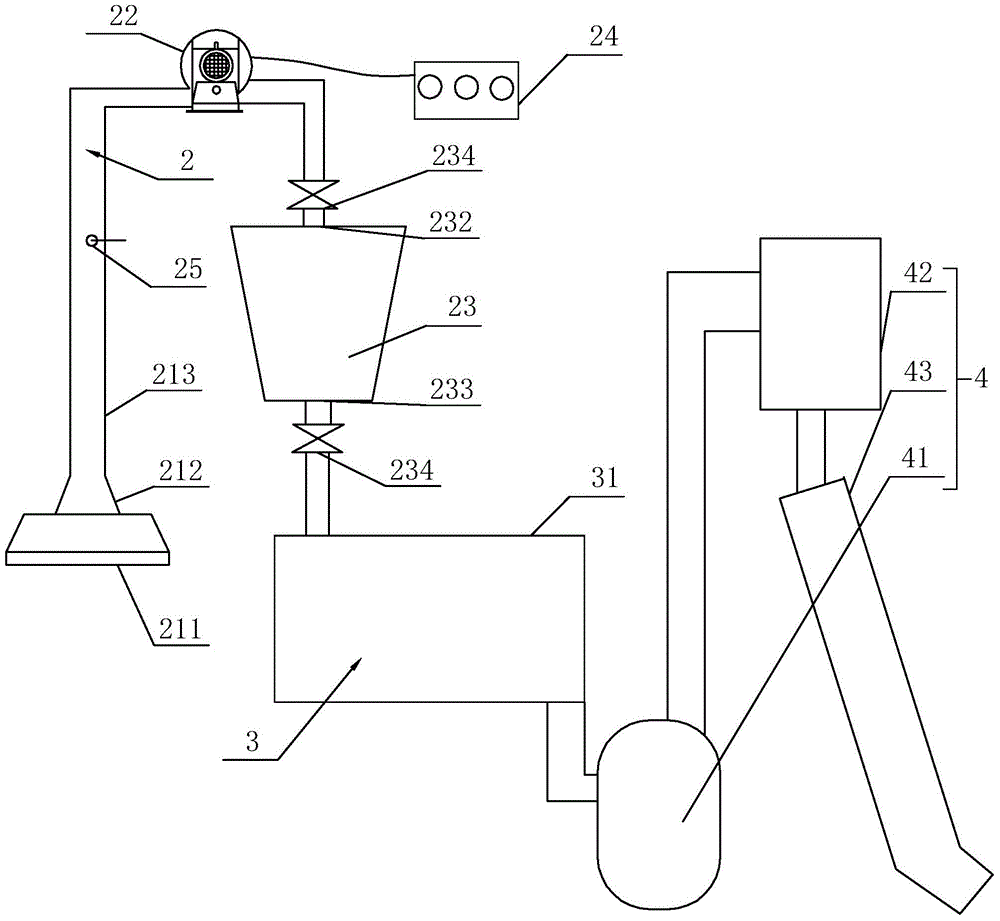

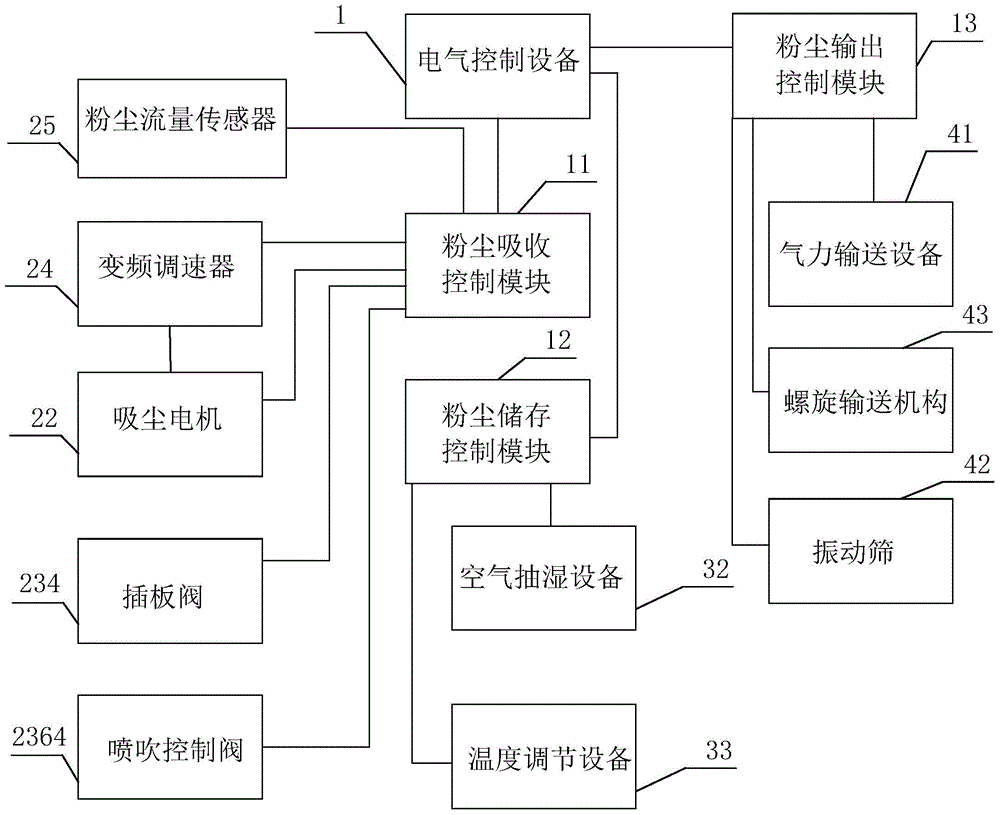

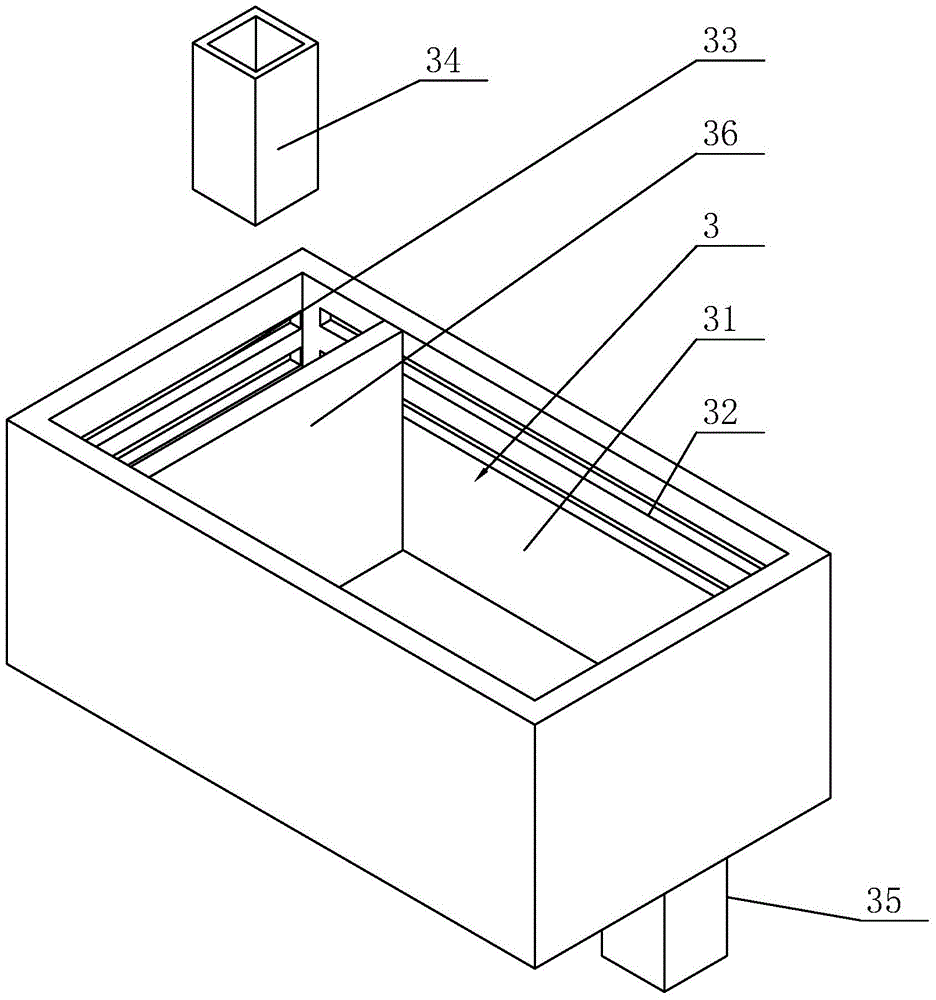

[0035] refer to Figure 1 to Figure 6 The embodiment of the dust recycling system of the present invention will be further described.

[0036] Such as Figure 1 to Figure 6 As shown, a dust recycling system includes an electrical control device 1, a dust absorption device 2, a dust storage device 3, and a dust output device 4, and the dust absorption device 2, the dust storage device 3, and the dust output device 4 are sequentially connected; The dust absorption device 2 includes a dust absorption channel 21, a dust suction fan 22 and a bag vacuum cleaner 23 for temporarily storing the absorbed dust, and the dust absorption channel 21, the dust suction fan 22 and the bag vacuum cleaner 23 are sequentially connected; The dust storage device 3 includes a dust settling tank 31, and the dust settling tank 31 is provided with an air dehumidifying device 32 and a temperature regulating device 33; the dust output device 4 includes a pneumatic conveying device 41, a vibrating screen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com