Color selector utilizing electric-control automatic distribution of material

A color sorter, automatic technology, applied in the field of color sorter, can solve the problems of high noise, poor mobility, complicated process, etc., and achieve the effect of high automation, fast response speed and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

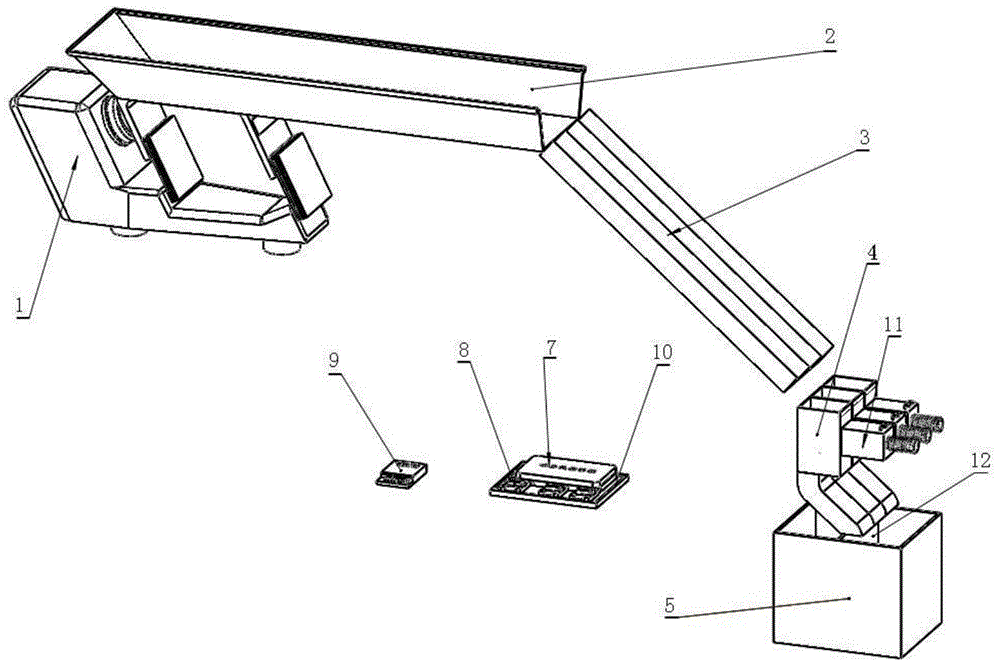

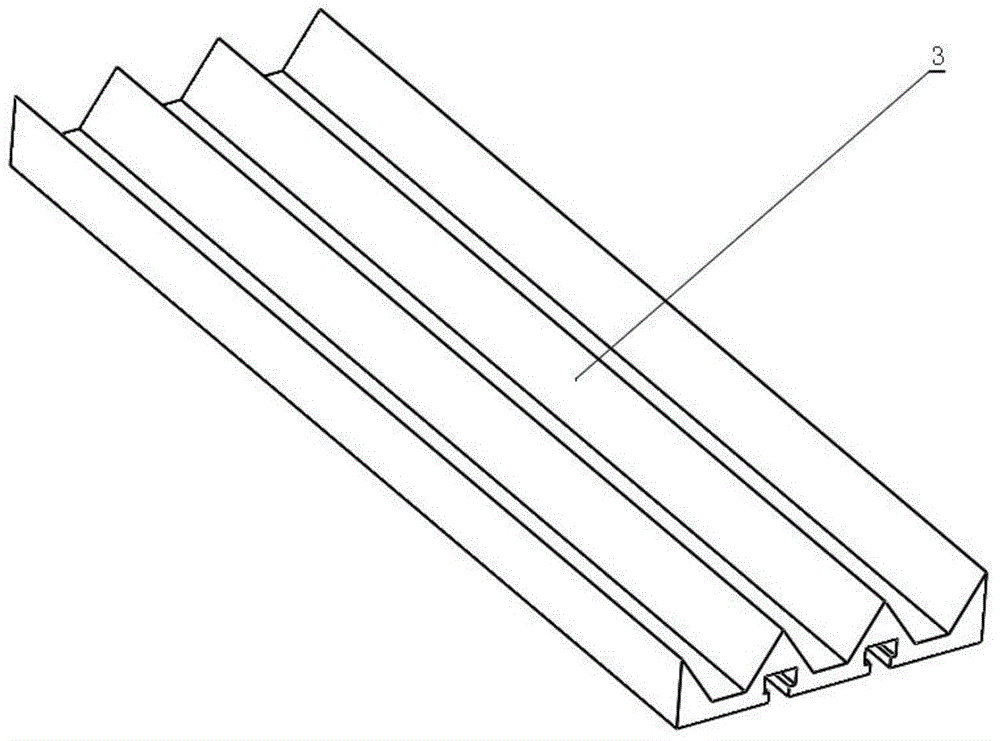

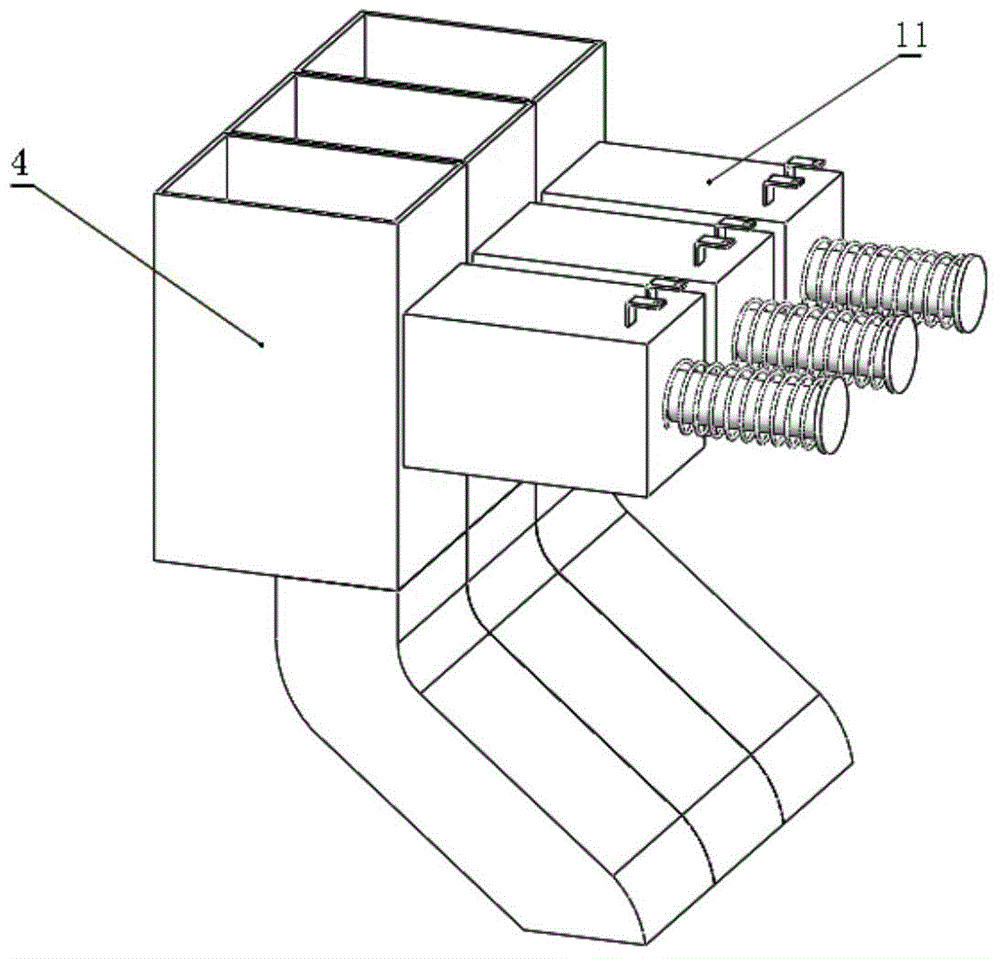

[0028] see Figure 1-Figure 3 , the present embodiment provides a color sorter that adopts electric control automatic material distribution, including a vibration feeder 1, a material tray 2, a chute 3, a material distribution bin 4, a material receiving bin 5 and a control unit, wherein the vibration feeder The feeder drives the tray to vibrate to feed the material; the chute is connected to the discharge port of the tray, and is set at an angle of 30° to the horizontal direction. The length of the chute is 570mm. The chute is equipped with 3 channels, and each channel is inverted ladder type; The distribution bin is located below the chute, and there is a gap between the chute and the distribution bin. Each channel corresponds to a distribution bin, and the three distribution bins are placed side by side. The material slides into the corresponding distribution bin from the chute, and the distribution bin A movable baffle 6 is set inside; the control unit includes an Atmega8 ...

Embodiment 2

[0031] This embodiment carries out experiments on 2000 grains of corn samples. The corn is naturally placed on the feeder pan of the vibrating feeder, so that it can move to the chute one by one with the vibration of the vibrating feeder, and fall into the bottom of the chute through the chute. In the distribution bin, it is calculated that in this way, each channel can drop at most 5 grains of corn per second, and the speed of the corn sliding out of the chute is 0.5m / s; the distribution device is calculated by using the Atmega8 single-chip microcomputer to send out PWM waves. The fastest action frequency, when the Atmega8 MCU sends a high level, the solid-state relay is closed, and the electromagnetic push rod quickly pushes the movable baffle to the position close to the inner wall of the distribution bin and close to the receiving bin A (the position away from the inner wall of the electromagnetic push rod ), at this time, the channel of the distribution bin corresponding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com