A fine-blanking die point-type blank holder and its processing method

A blankholder and point-type technology, which is applied in the fine-blanking mold point-type blankholder and its processing field, can solve the problems of high processing cost, material waste, and increased fine-blanking mold manufacturing costs, and achieve low manufacturing costs and reduced The effect of processing cost and easy processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

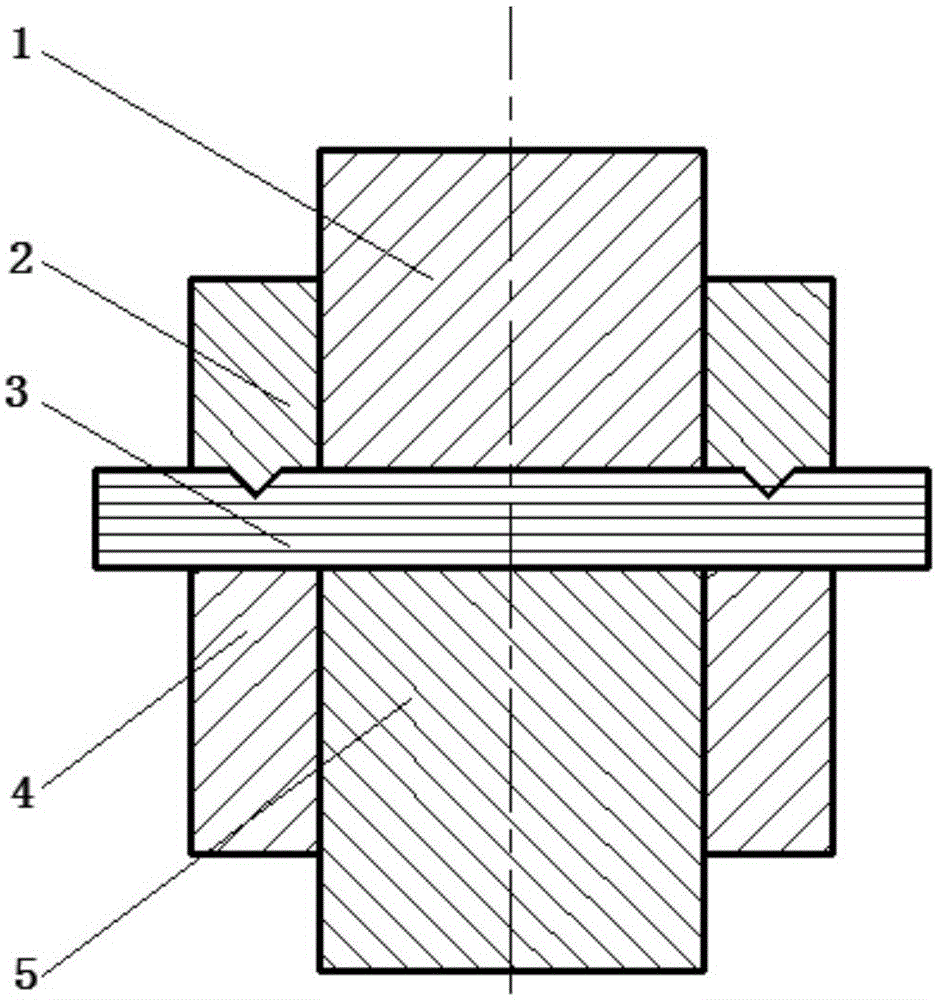

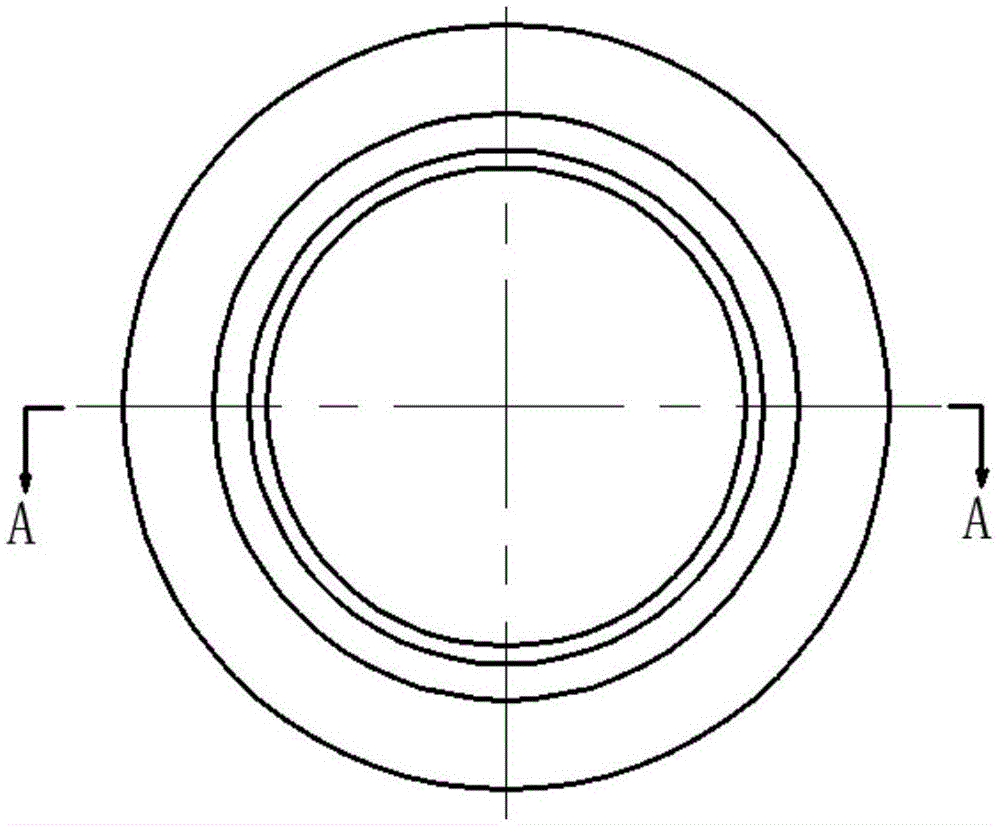

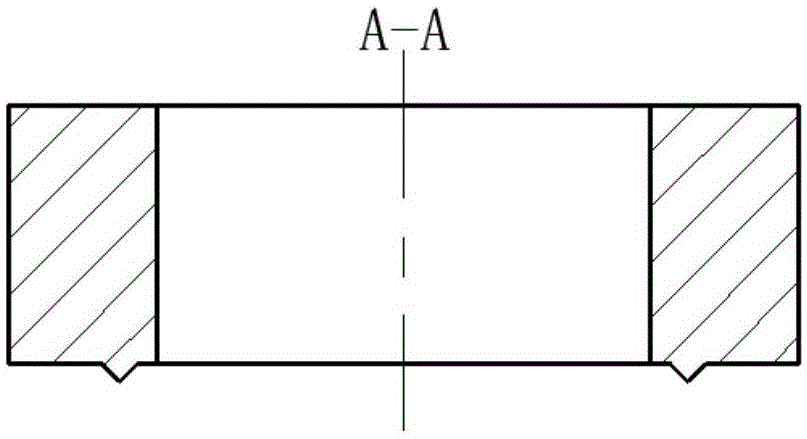

[0027] A point-type blankholder for a fine-blanking die, which includes a point-type blankholder body, a group of convex points are evenly distributed on the lower surface of the point-type blankholder body along the outline of a part to be formed by fine blanking. The starting point is used to compress the blank so that the blank forms a three-way hydrostatic stress state during the fine blanking process.

[0028] The diameter (maximum diameter) of the raised point is 0.6-1.8mm. The raised point is hemispherical.

[0029] The above-mentioned processing method of a point-type blank holder of a fine blanking die (the point-type blank holder adopts electric spark machining), it comprises the following steps:

[0030] 1) According to the design that a set of convex points (that is, the designed convex points) are evenly distributed on the lower surface of the point-type blank holder body along the outline of the required fine-blanking part, use a drill bit equal to the diameter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com