Reconstructible casting molding fast 3D printing method

A 3D printing and casting molding technology, applied in the field of reconfigurable casting molding rapid 3D printing, can solve the problems of immaturity and low printing efficiency, and achieve the effect of improving speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

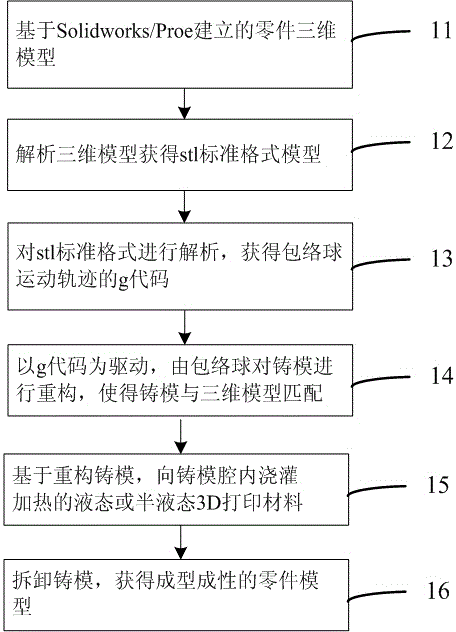

[0029] Such as figure 1 As shown, a rapid 3D printing method for reconfigurable casting molding, based on reconfigurable casting molds, includes steps:

[0030] Step 11, based on Solidwork, Pro / E or UG three-dimensional modeling software, the three-dimensional model of parts is set up;

[0031] Step 12, analyzing the three-dimensional model to obtain a standard format model in stl format;

[0032] Step 13, parsing the standard format model of the stl format to obtain the g code of the envelope ball trajectory;

[0033] Step 14, based on the g code as the drive, the reconfigurable casting mold is reconstructed by the envelope ball, so that the reconstructed casting mold matches the three-dimensional model of the component;

[0034] Step 15. Based on the reconstructed reconfigurable mold, pour heated liquid or semi-liquid 3D printing material into the mold cavity;

[0035] Step 16, after pouring is completed, the casting mold is disassembled to obtain a moldable part model. ...

Embodiment 2

[0038] This embodiment describes the 3D printing process of the present invention in detail for spherical parts.

[0039] Such as Figure 4 The schematic diagram of the printing molding process of the casting method of spherical parts is shown, a fast 3D printing method for reconfigurable casting molding, based on reconfigurable casting molds, including steps:

[0040] Step 1, establish the spherical three-dimensional model 41 of parts based on Solidwork, Pro / E or three-dimensional modeling software;

[0041] Step 2, analyzing the spherical three-dimensional model 41 to obtain a standard format model 42 in stl format;

[0042] Step 3, parsing the standard format model 42 of the stl format to obtain the g code of the envelope ball trajectory;

[0043] Step 4, based on the g code as the drive, the reconfigurable mold is reconstructed by the envelope ball, so that the reconstructed mold matches the three-dimensional model of the parts;

[0044] Step 5. Based on the reconstruct...

Embodiment 3

[0049] This embodiment describes the 3D printing process of the present invention in detail for spinning cone parts.

[0050] Such as Figure 5 The schematic diagram of the printing and molding process of the casting method of spinning cone parts is shown, a fast 3D printing method for reconfigurable casting molding, based on reconfigurable casting molds, including steps:

[0051] Step 1, based on Solidwork, Pro / E three-dimensional modeling software, set up the spinning cone three-dimensional model 51 of parts;

[0052] Step 2. Analyzing the spinning cone three-dimensional model 51 to obtain a standard format model 52 in stl format;

[0053] Step 3, parsing the standard format model 52 of the stl format to obtain the g code of the envelope ball trajectory;

[0054] Step 4, based on the g code as the drive, the reconfigurable mold is reconstructed by the envelope ball, so that the reconstructed mold matches the three-dimensional model of the parts;

[0055] Step 5. Based on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com