Catenary suspension string preplanning platform

A catenary and platform technology, applied in the direction of overhead lines, etc., can solve the problems of poor precision, high scrap rate, low efficiency, etc., and achieve the effect of solving poor precision and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

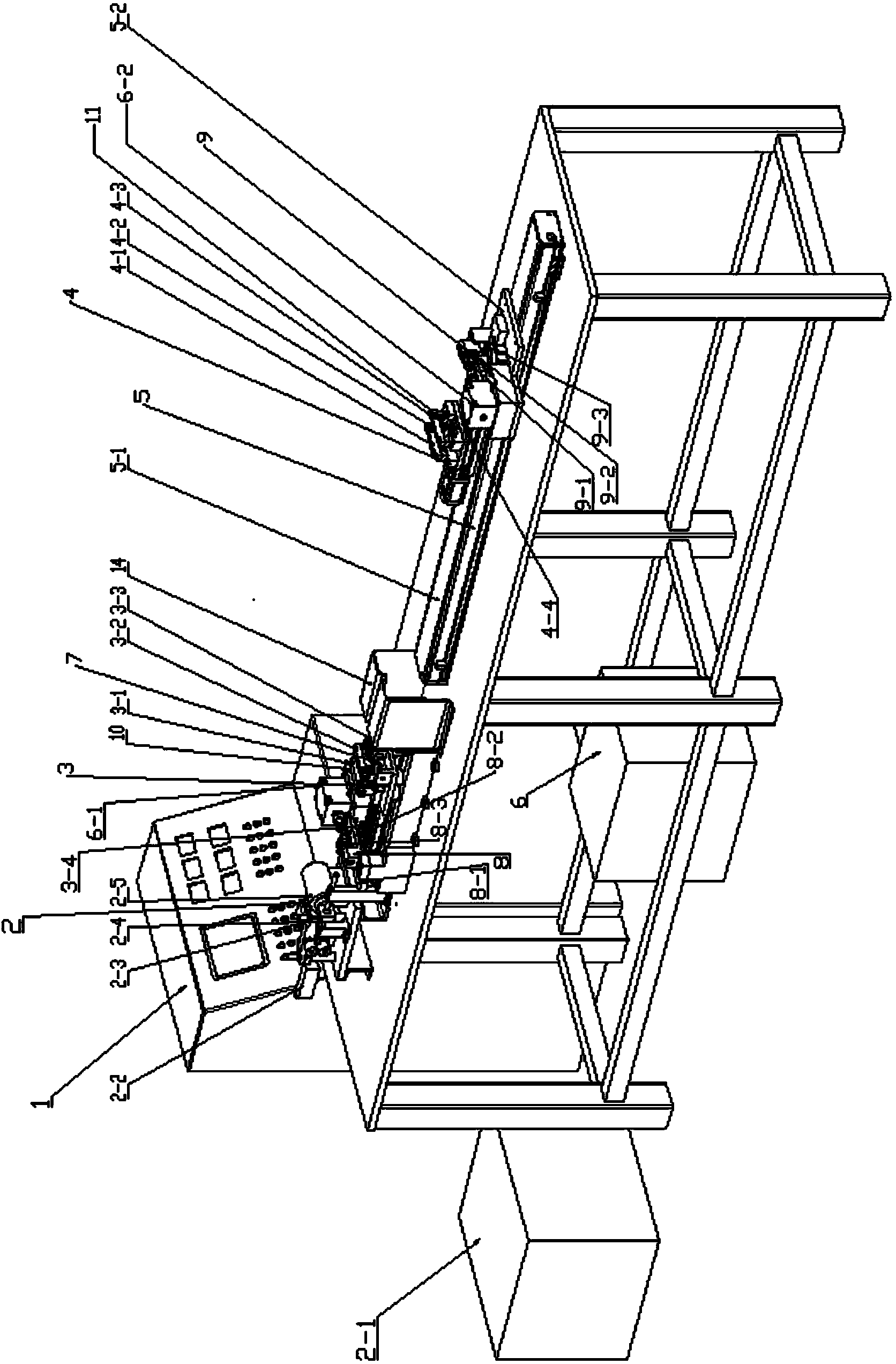

[0034] Specific embodiments of the invention will be described in detail below in conjunction with the accompanying drawings.

[0035] The production and processing of hanging strings generally includes two steps, the first is wire feeding, and the specific process is as follows:

[0036] The electric control device (1) sends wire feeding signals and parameter information to other devices, and moves the left copper casing pushing device (3) to the left stop point of the left linear motion module (3-4) with a stroke of 300mm, and the length of the hanging string is controlled Both the device (5) and the right copper casing pushing device (4) are moved to their respective left dead centers, and the left copper casing clamping lever cylinder (3-1) and the right copper casing clamping lever cylinder (4-1) are started Hold the left copper sleeve (10) and the right copper sleeve (11) respectively; the purchased copper strands pass through the pay-off machine (2-1), the straightener ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com