Device and method for measuring liquid level height of molten silicon in single crystal furnace

A liquid level, single crystal furnace technology, applied in the self-melting liquid pulling method, single crystal growth, single crystal growth and other directions, can solve the problems of complex algorithm and low detection accuracy, achieve high measurement accuracy, improve accuracy, The effect of simplifying the complexity of the installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

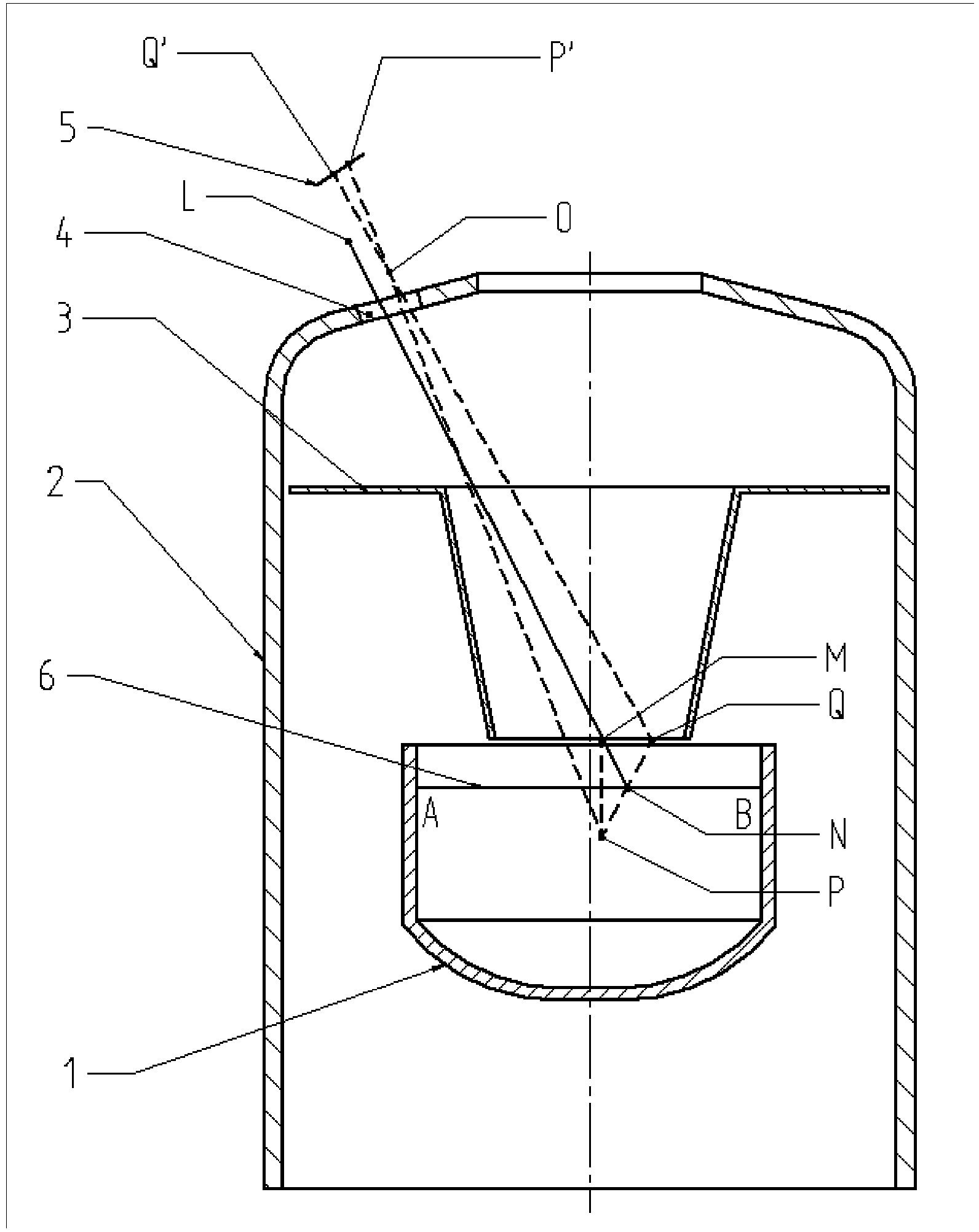

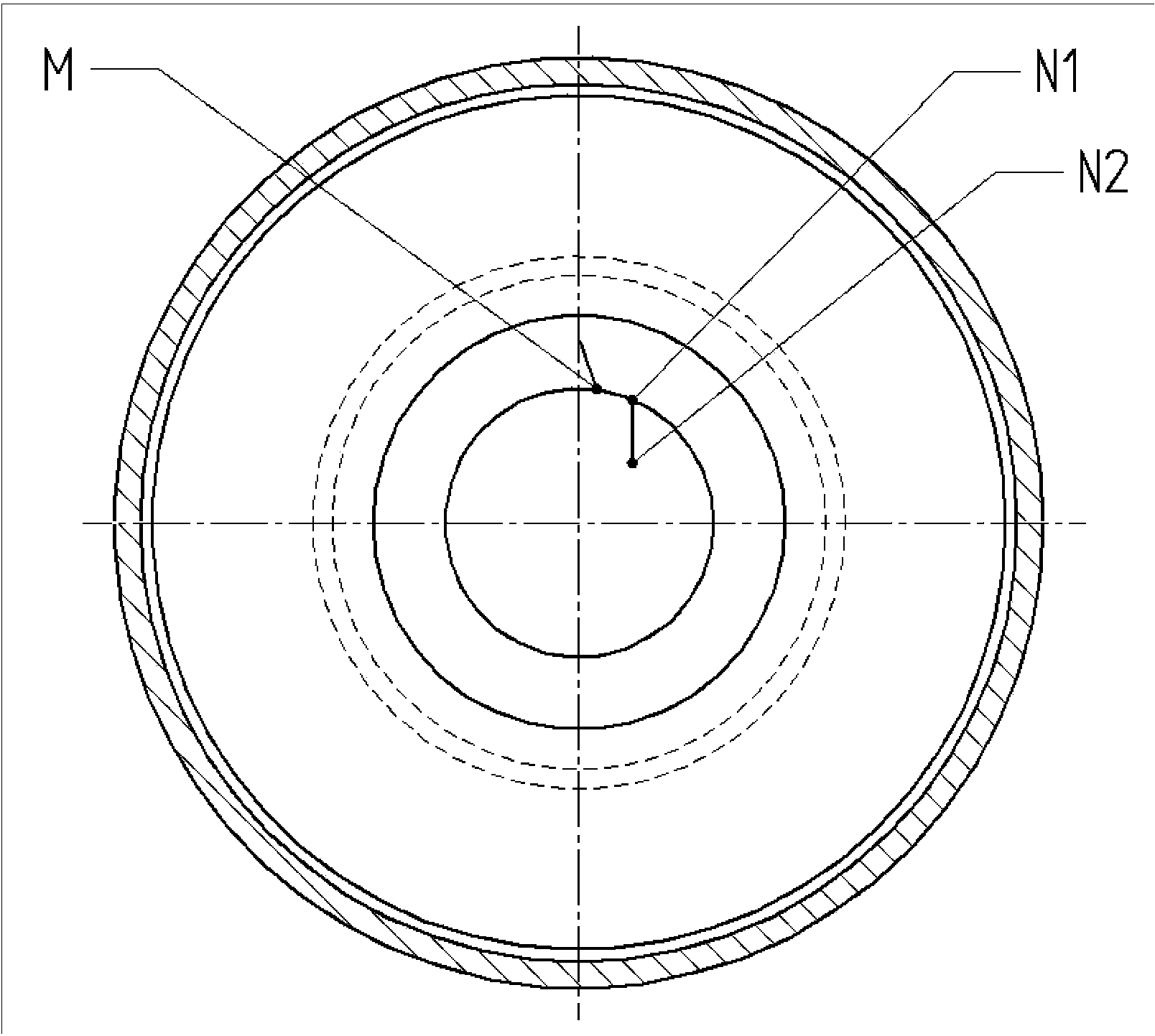

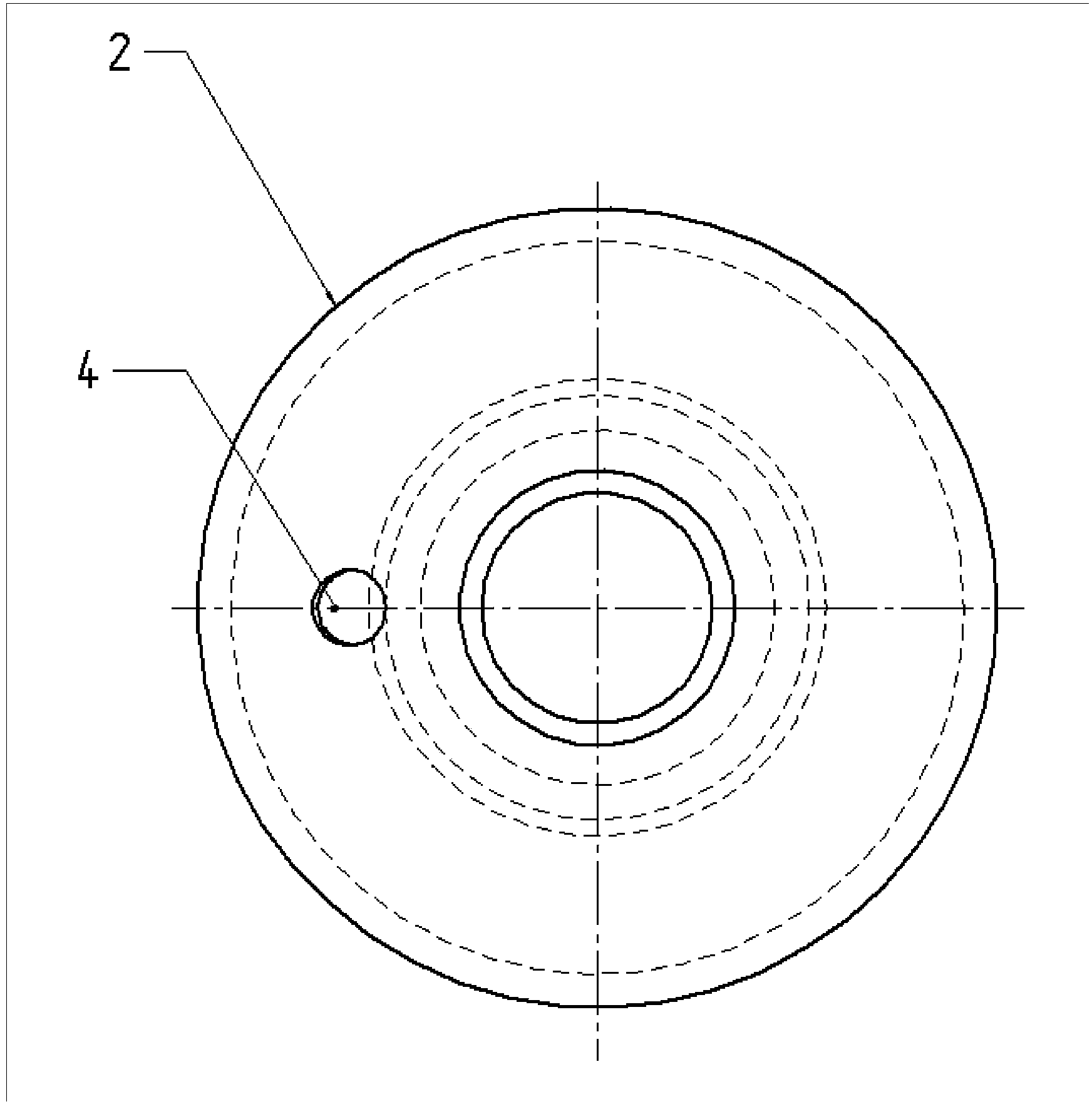

[0028] Example: The camera model is SQ-S20C-G30-C, and the pixel size is 5.5 μm. Since the height of the liquid level cannot be directly measured during the crystal pulling process, the liquid level is replaced by a mirror surface. The measured distance between the mirror surface and the heat shield is 37.5 mm, through calibration, the angle between the optical axis of the lens and the liquid surface is 22.1 degrees. When the measured size of the actual calibration object is 80mm, the length of the object in the image is 195 pixels, and the magnification k of the lens can be obtained as 0.0134 times. The projected distance of the coordinates of Q' and P' measured at this time in the direction perpendicular to the laser stripes is 135 pixels. According to the size of the CCD pixel, the actual distance between Q' and P' is 0.743mm. According to the formula (1) It can be obtained that the distance between the liquid surface and the bottom edge of the heat shield is 37.09mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com