Method and device for a fiber web production line through a coating substance

A fiber web and fiber generation technology, which is applied in fiber raw material processing, pulp raw material addition process, textile and papermaking, etc., can solve the problems of high cost and low fiber web running performance, and achieve good retention and simple device structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In the following description, unless otherwise specified, the same reference numerals refer to the same or corresponding parts or components of the above examples.

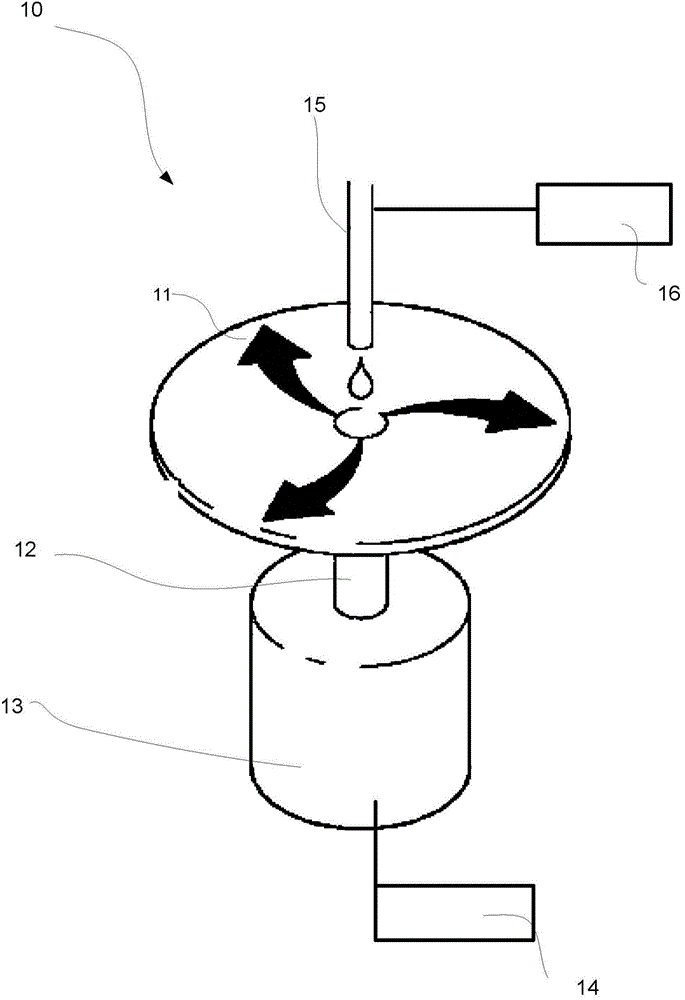

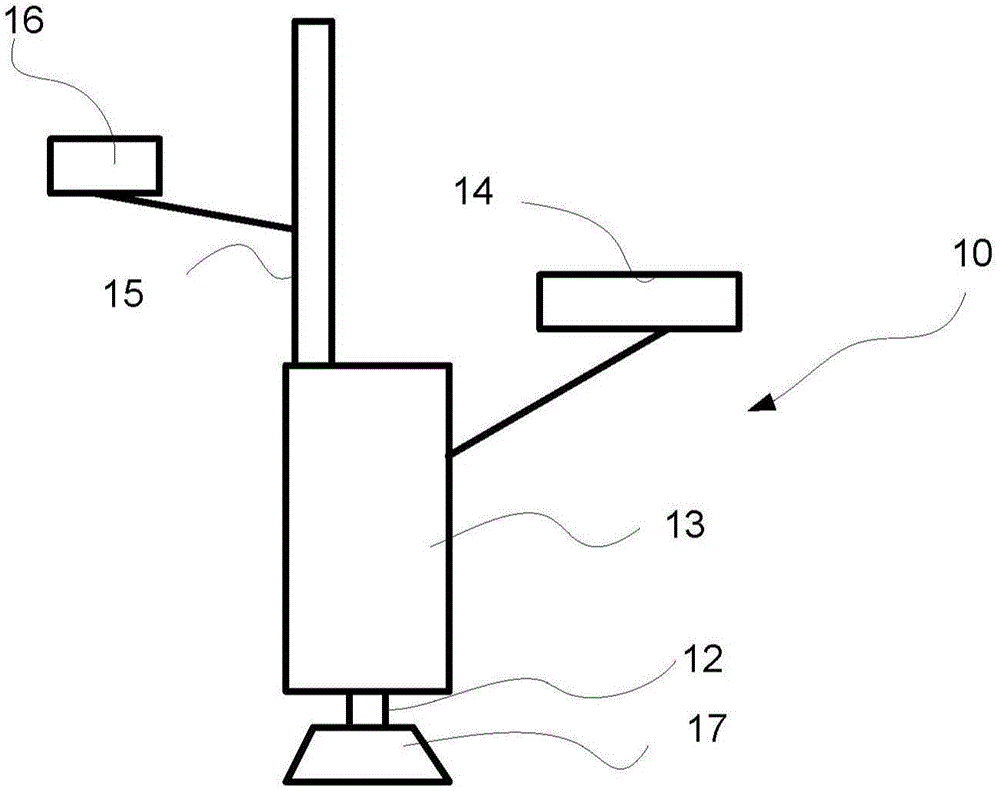

[0062] exist figure 1 An example of a spin coating device 10 is schematically shown in , which is a rotating disc atomizer and includes a disc 11 rotatably arranged on a shaft 12 . The rotary disc atomizer also includes an actuator 13 for providing the rotary motion of the disc 11 . The substance to be coated is supplied on the turntable 11 via the fluid line 15 or a corresponding inlet channel. The control means 14 control the rotational speed of the disc 11 by controlling the actuator 13 , while the control means 16 control the amount of substance to be fed on the disc 11 . When the substance to be applied to form the fiber web or the substance to be applied to the fiber web has been fed on the turntable 11 through the fluid pipe 15, it is sprayed and misted by centrifugal force on all edges of the disk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com