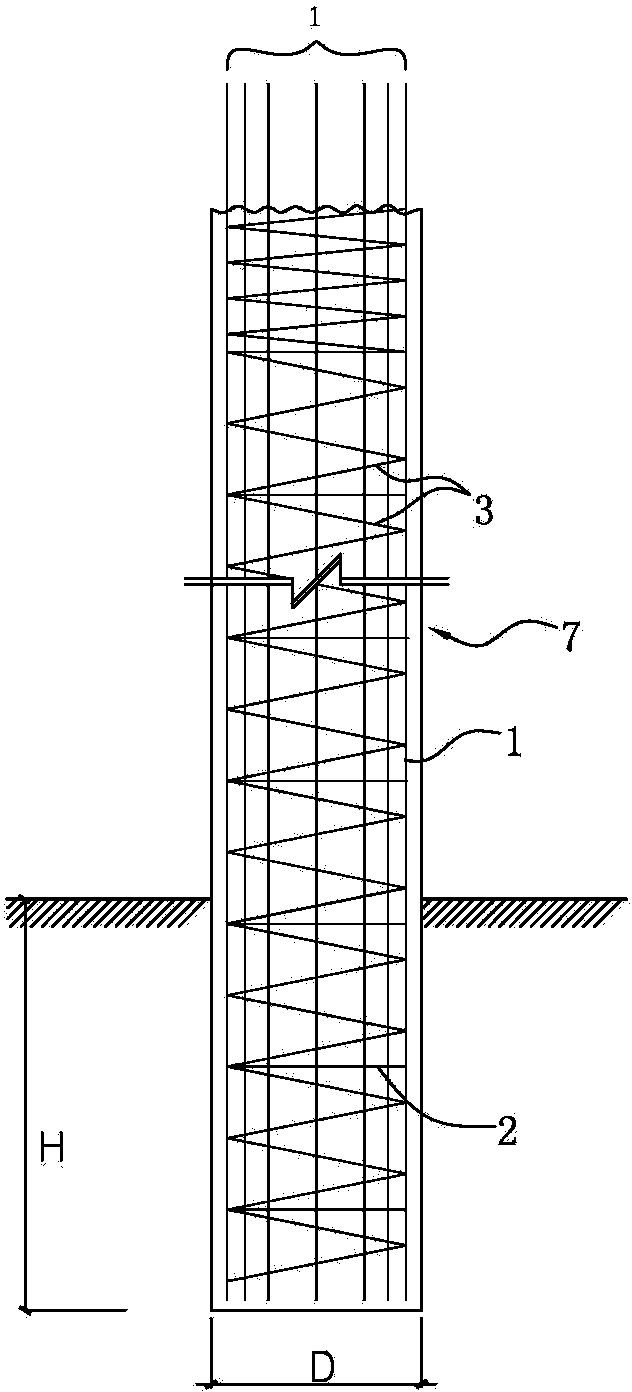

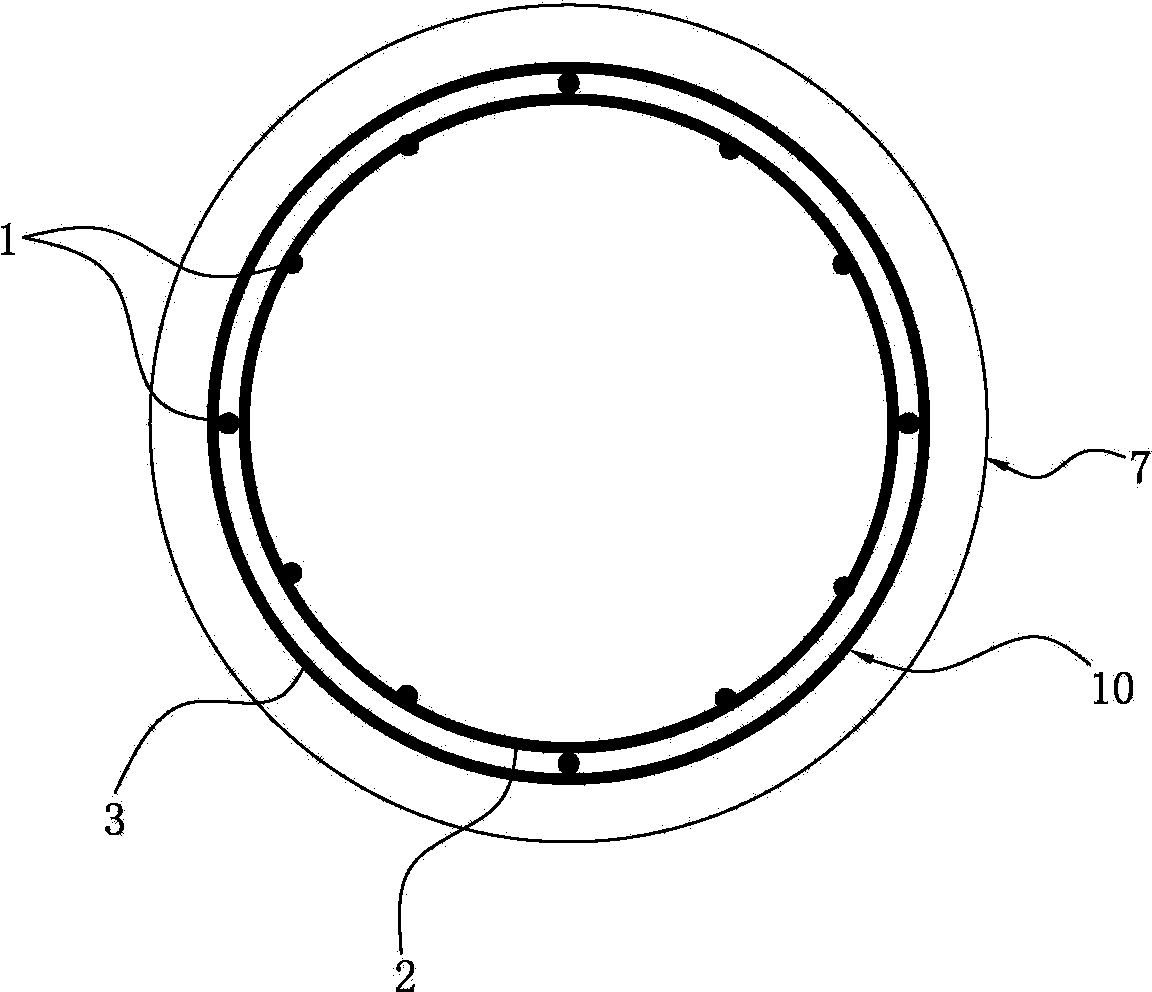

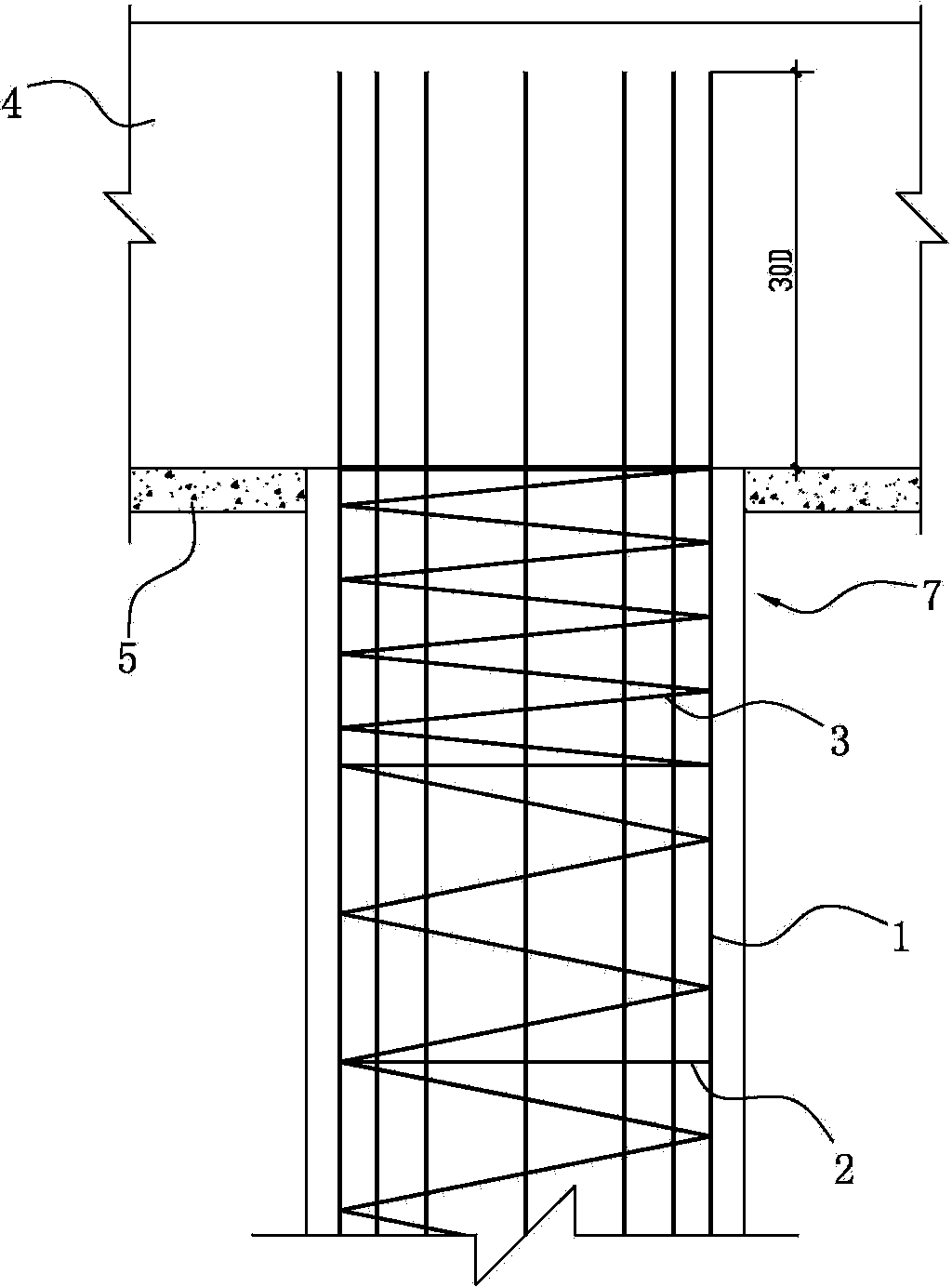

Method for constructing large-diameter reinforced concrete cast-in-place pile supporting stand column

A technology of reinforced concrete and construction method, which is applied in the direction of excavation, sheet pile wall, foundation structure engineering, etc., to achieve the effect of saving project cost, simple operation and controllable quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0039] Panyu Shigang East Lot Development Project is located on Shigang East Road, Panyu District, Guangzhou City, with basements on the first to second floors, the building ±0.00 is equivalent to the Guangzhou urban construction elevation of 7.600m, the perimeter of the foundation pit is about 660m, and the excavation depth of the foundation pit is about 6.4 ~10.2m. Within the excavation depth of the foundation pit, the filling soil, silt, silt, plastic to hard sandy cohesive soil, etc. are sequentially exposed. Partially located in plastic to hard plastic sandy cohesive soil layer. Around the foundation pit is a 6-storey residential building close to the municipal main road and pipe pile foundation. There are sewage pipes, water supply pipes, cable trenches, etc. According to the excavation depth of the foundation pit and the geological conditions of the site, the foundation pit support of this project is mainly supported by piles. The support form is partially supported by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com