A method for improving the quiet zone performance of a microwave anechoic chamber and a modular dielectric barrier

A microwave anechoic chamber and modular technology, which is applied in the direction of architecture and building construction, can solve the problems of performance degradation of absorbing materials, influence of reflection level index in quiet zone, influence of antenna measurement or simulation test accuracy, etc., so as to improve performance, Effect of size reduction and construction cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail in conjunction with the accompanying drawings and embodiments.

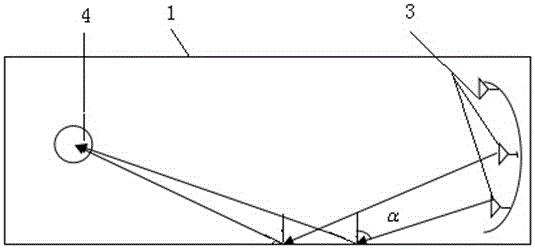

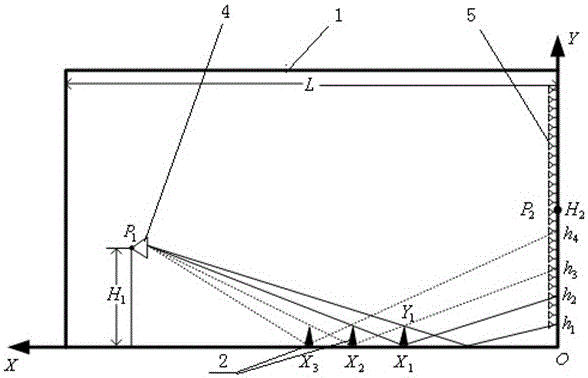

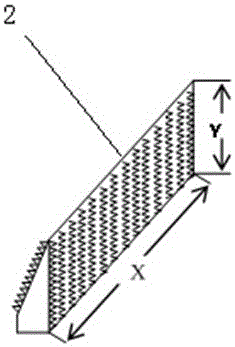

[0034] like figure 1 , 2 As shown in , 3, a modular dielectric barrier for improving the performance of the quiet zone of the microwave anechoic chamber is characterized in that: the modular dielectric barrier 2 located in the microwave anechoic chamber 1 is formed by connecting a right-angled triangle with a rectangular base 2.2, and the right-angled triangle An acute angle of the body is 20-30°, the right-angled surface of the modular dielectric barrier 2 is facing the curtain wall 5, and the slope of the modular dielectric barrier 2 is facing the center of the quiet zone 4; and the slope of the right-angled triangle is provided with a wave-absorbing material layer 2.1 A wave-absorbing material layer 2.1 is respectively arranged on the ground plane shielding body of the microwave anechoic chamber where the vertical plane of the right-angled trian...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com