Coal-fired power plant furnace chamber flame judging method based on double images

A coal-fired power plant, double-image technology, applied in the direction of combustion control, instruments, character and pattern recognition, etc., can solve the problems of energy waste, heavy pollution, long service life, etc., achieve accurate automatic monitoring and control, and realize safety, The effect of the simple and easy-to-understand discrimination method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] 1. Acquisition of the original double image of the furnace flame

[0022] Select an appropriate dual-image acquisition system (such as two infrared flame detectors with an image capture angle of 90° and installed in a horizontal position) to obtain the original image of the real-time combustion furnace flame, and transmit the acquired flame image to the host computer through the data line, and then The center of mass of the flame image is determined by processing and computing the two images acquired by the host computer.

[0023] First of all, considering the instability of the furnace flame conditions, the obtained original image contains more noise factors, which affects the clarity of the image, so the original image is pre-processed first;

[0024] 2. Preprocessing of each original single image

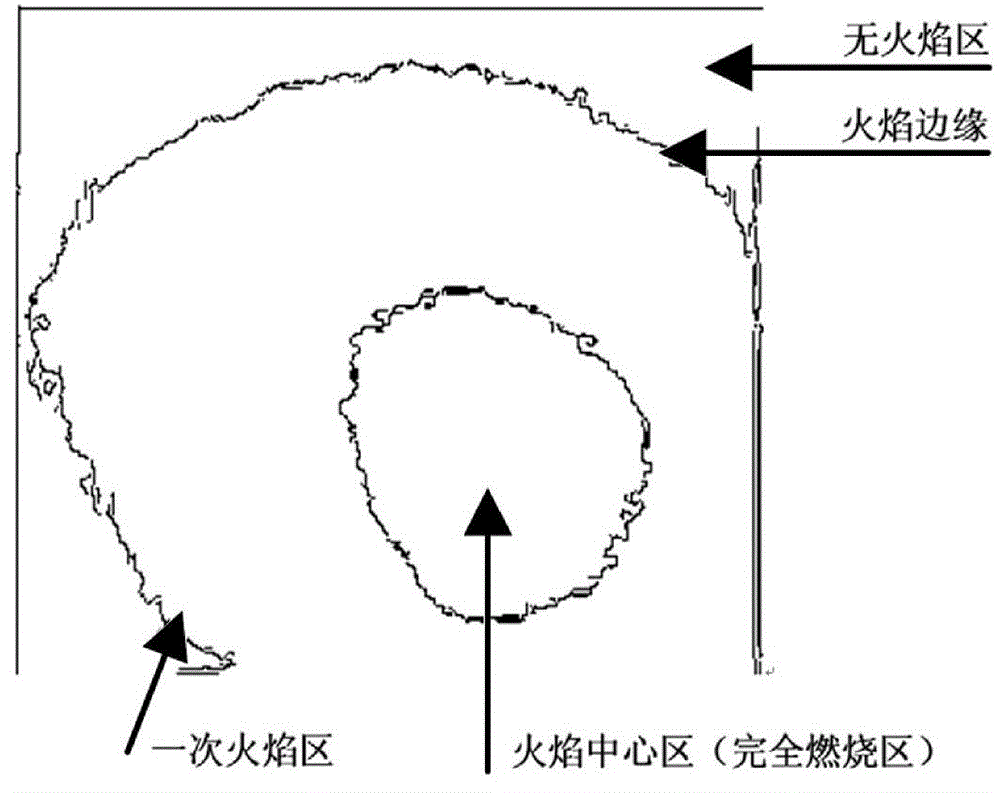

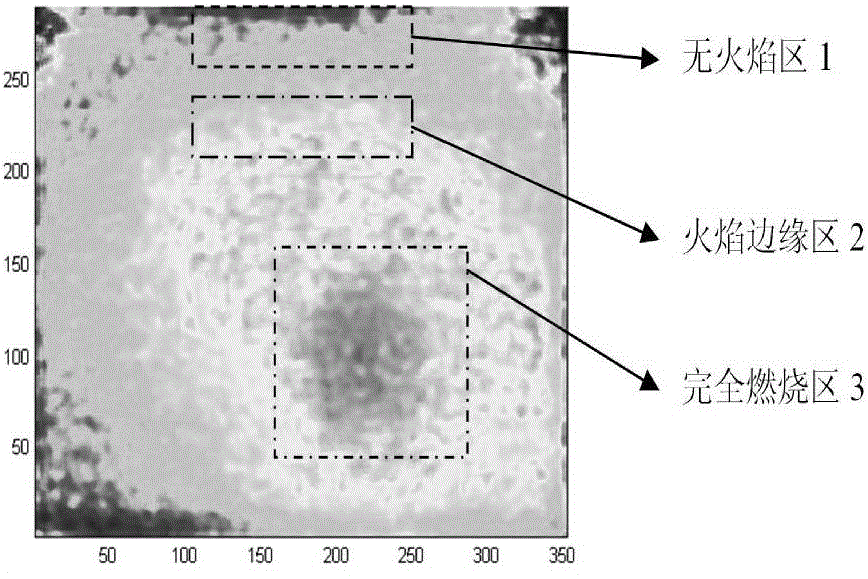

[0025] According to the effective characteristics of the flame image, in order to suppress the noise caused by various interferences in the boiler, imaging process, and s...

example 1

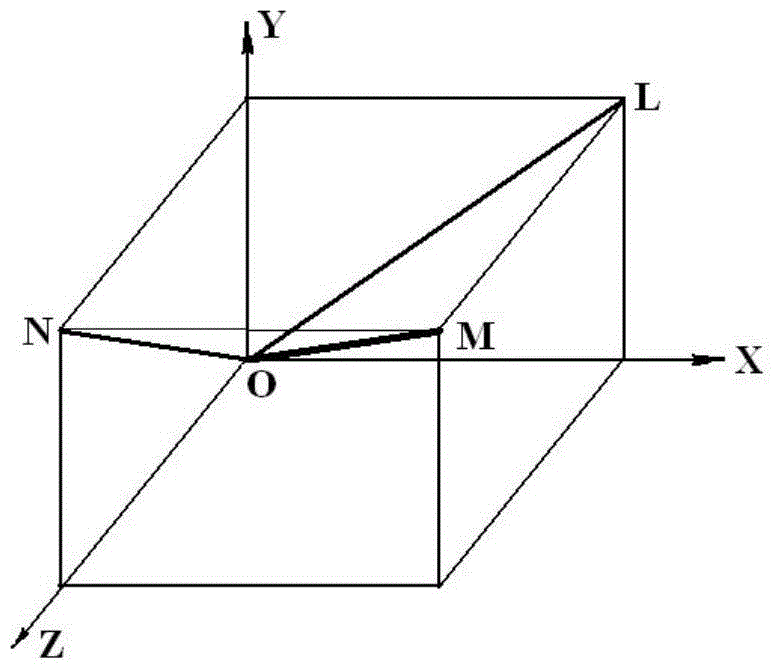

[0060] Below to image 3 The spatial structure image is shown to illustrate the calculation of the centroid offset distance of the actual flame image:

[0061] like image 3 As shown, if the original centroid is at point O, and the current flame centroid is M, a flame image is obtained on the XOY plane, and the offset distance OL is calculated. If the OL value is greater than the set effective fluctuation area, an early warning or alarm will be issued without Then calculate the offset distance of the actual flame burning center of mass; similarly, get the flame image on the vertical XOY plane on the YOZ plane, and calculate the offset distance ON. If the ON value is greater than the set effective fluctuation area, a direct warning or alarm will be issued.

[0062] Calculate the center of mass point M of the actual flame combustion from OL and ON to get OM, and the amount of pulverized coal and hot air is determined by the value of OM.

[0063] The coal-fired boiler in a powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com