Organic electroluminescent device and preparation method thereof

An electroluminescence device and a luminescence technology, which are applied in the manufacture of organic semiconductor devices, electric solid devices, semiconductor/solid state devices, etc., can solve the problems of light loss, poor refractive index, low light performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

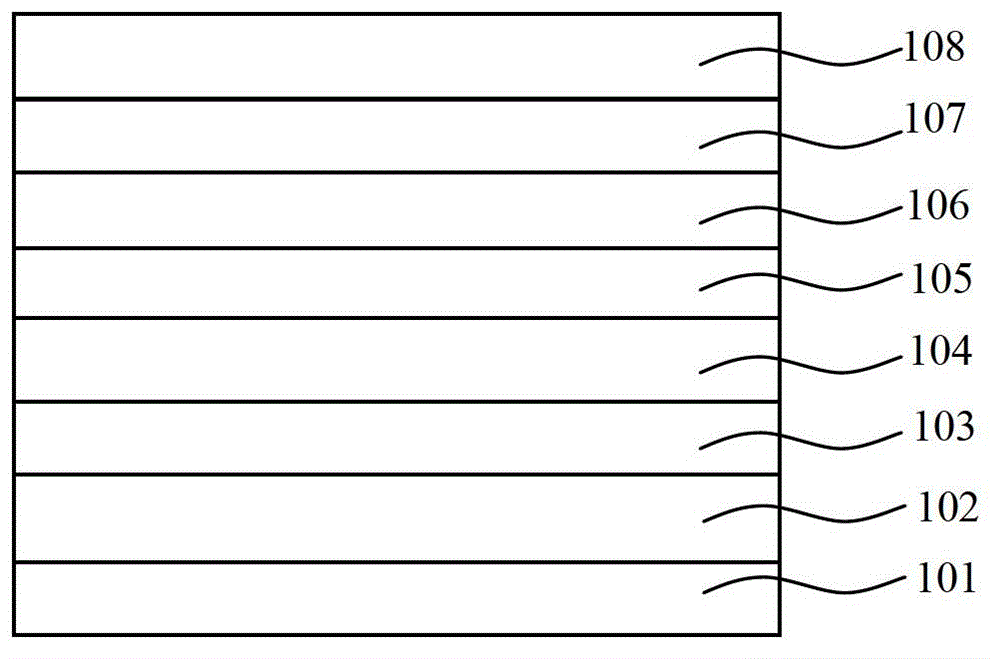

[0077] A method for preparing an organic electroluminescent device, comprising the following steps:

[0078] (1) After rinsing the N-LASF44 glass with distilled water and ethanol, soak it in isopropanol for one night to obtain a clean glass substrate;

[0079] (2) In the high vacuum coating system (Shenyang Scientific Instrument Development Center Co., Ltd.), the pressure is 5×10 -4 Under the condition of Pa, thermal resistance vapor deposition of Ta on one side of a clean glass substrate at a deposition rate of 3nm / s 2 o 5 : CuPc mixture to prepare the light extraction layer with a thickness of 400nm, and then carry out heat preservation annealing treatment for 30min under the condition of 200°C, wherein Ta 2 o 5 : The CuPc mixture is CuPc doped into Ta according to the mass fraction of 20%. 2 o 5 mixture formed in

[0080] (3) At an accelerating voltage of 400V, a magnetic field of 100G, and a power density of 20W / cm 2 Under the condition of , the ITO anode was prepar...

Embodiment 2

[0089] A method for preparing an organic electroluminescent device, comprising the following steps:

[0090] (1) After rinsing the N-LASF36 glass with distilled water and ethanol, soak it in isopropanol for one night to obtain a clean glass substrate;

[0091] (2) In the high vacuum coating system (Shenyang Scientific Instrument Development Center Co., Ltd.), the pressure is 2×10 -3 Under the condition of Pa, thermal resistance evaporation of Nb on one side of a clean glass substrate with an evaporation rate of 1nm / s 2 o 5 : ZnPc mixture to prepare the light extraction layer, the thickness is 50nm, then carry out heat preservation annealing treatment under 50 ℃ condition for 60min, wherein Nb 2 o 5 : ZnPc mixture is ZnPc doped to Nb according to 10% mass fraction 2 o 5 mixture formed in

[0092] (3) At an accelerating voltage of 300V, a magnetic field of 50G, and a power density of 1W / cm 2 Under the condition of , the IZO anode was prepared on the other side of the glas...

Embodiment 3

[0097] (1) After rinsing the N-LASF31A glass with distilled water and ethanol, soak it in isopropanol for one night to obtain a clean glass substrate;

[0098] (2) In the high vacuum coating system (Shenyang Scientific Instrument Development Center Co., Ltd.), the pressure is 5×10 -5 Under the condition of Pa, thermal resistance vapor deposition of VO on one side of a clean glass substrate at a deposition rate of 10nm / s 2 : MgPc mixture to prepare the light extraction layer, the thickness is 500nm, then carry out the heat preservation annealing treatment under 300 ° C for 10min, wherein VO 2 : MgPc mixture is MgPc according to mass fraction 10% doped to VO 2 mixture formed in

[0099] (3) At an acceleration voltage of 800V, a magnetic field of 200G, and a power density of 40W / cm 2 Under the condition of , the AZO anode was prepared on the other side of the glass substrate by magnetron sputtering, with a thickness of 300nm;

[0100] (4) At a pressure of 5×10 -5 Under the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com