High-efficiency acoustic anionic putty powder for hidden flat acoustic speaker

A hidden, negative ion technology, applied in the direction of filling slurry, etc., can solve the problems of increasing system heat generation and instability factors, low efficiency of audio system, and reduction of sound loudness, etc., to achieve light weight, high cost performance, and sound wave blocking small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

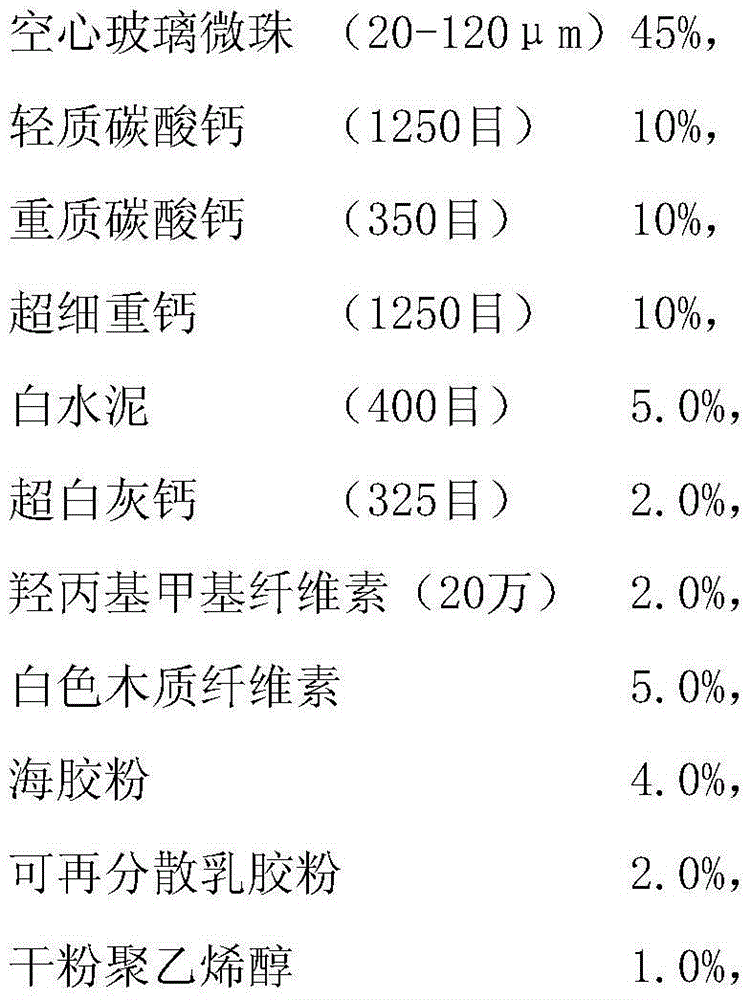

[0024] Weigh each component according to the following volume percentages:

[0025]

[0026]

[0027] The above raw materials are prepared according to the volume percentage, stirred evenly, and can be packaged and stored. When used, the putty powder and water are mixed according to the volume ratio of 2:1 to form a paste.

Embodiment 2

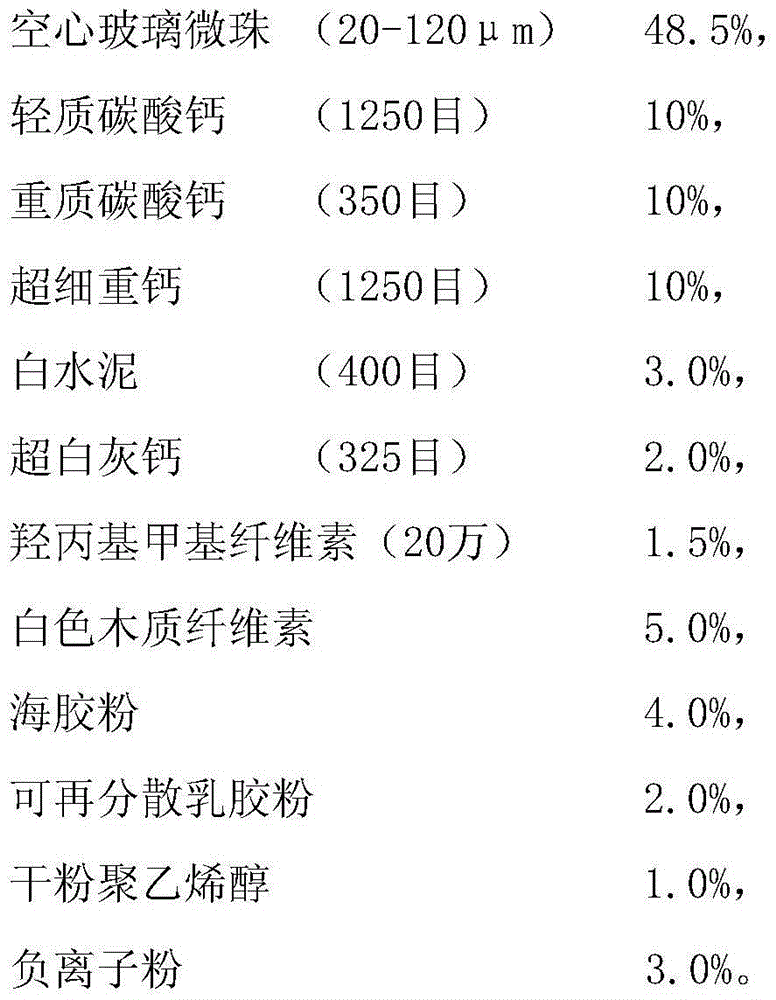

[0029]

[0030] The volume percentage of the above raw materials is prepared and stirred evenly. It can be packaged and stored. When in use, mix the putty powder and water according to the volume ratio of 2:1 to form a paste.

Embodiment 3

[0032]

[0033] The volume percentage of the above raw materials is prepared and stirred evenly. It can be packaged and stored. When in use, mix the putty powder and water according to the volume ratio of 2:1 to form a paste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com